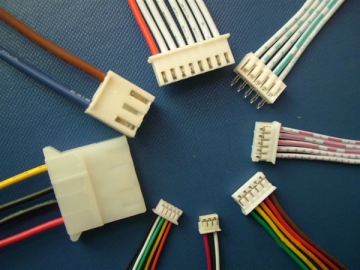

Stamping Dies for Wire Terminals

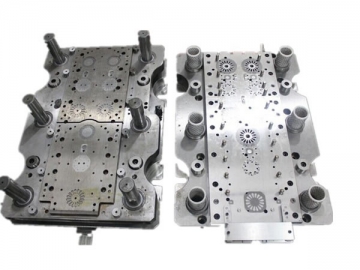

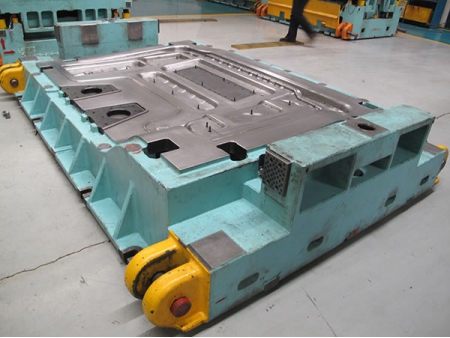

Wire terminals are mostly made using stamping dies. They are economical to manufacture, which means manufacturers make very little money off low-volume orders.

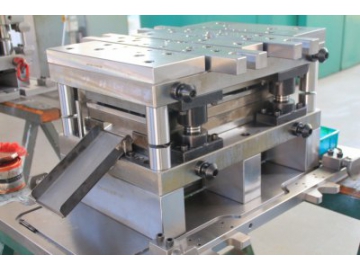

We understand customers need quality stamping dies that will withstand repeated usage in high-volume productions of wire terminals. Because of that, we carefully test and design each aspect of our tooling solutions to ensure you can produce large volumes of quality wire terminals fast and efficiently.

Wire terminals vary in construction, size, and materials. The most commonly used are barrier strips, quick-disconnect terminals, fixed terminal blocks, and wire lugs. This means stamping dies should be custom built to meet particular specifications on each wire terminal.

Bottom Line

1. With a "less is more" mindset, we encourage designers to use materials sparingly in the initial die design stage. While the pitch of a terminal block is usually specified before- hand by the customer, engineers usually consider making the terminal block into two rows to shorten the overall length.

2. Our tooling engineers usually perform measuring operations on the die in a single step to minimize the accumulated error in measurements.

3. For customers with strict requirements on the end angle and size, we'll adjust the process on the punch press to meet them.

If you are in need of stamping dies for wire terminal production, simply give us a call. We aim to provide you with the right metal stamping services to meet your needs.