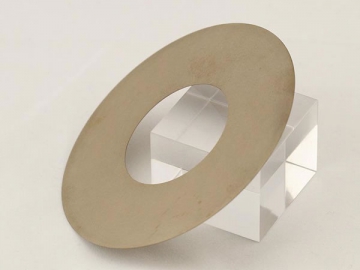

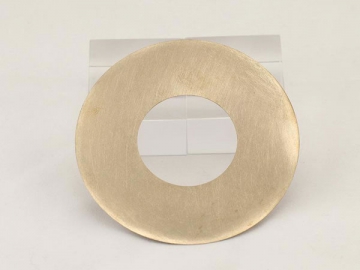

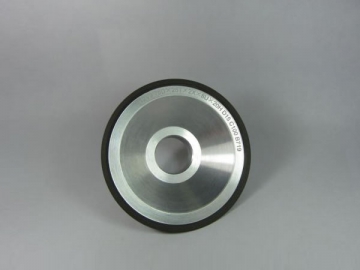

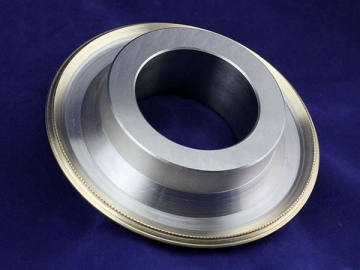

Slotting Wheels

This page is specifically focused on our slotting wheels. The slotting wheel -also commonly referred to as a cutting wheel-is made from diamond abrasives and metal bonds using a sintering process. It is primarily used for cutting or slotting of oxidation film with a high content of A12O3 or a metal oxide film resistance. During the slotting process, the diamond cutting disc requires no enforced cooling conditions, providing a high precision, a narrow slot and a long service life.

Direction for Use

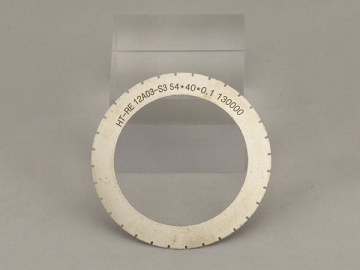

1. Insulation

During use, please use a cleat insulator and insulation gasket to keep the abrasive disc insulated from the spindle of the grooving machine. To be more specific, the outer diameter of the insulation gasket is matched with the inner diameter of the slotting wheel; and the inner diameter of the insulation gasket is matched with the machine spindle.

2. Dressing

Use a diamond file or sharpening stone to dress the new slotting wheel before use, to ensure that the external circle can be concentric and burr free.

3. Rotary Direction

If the rotary direction of resistance is opposite to that of the slotting wheel, the slotting effect will be better.