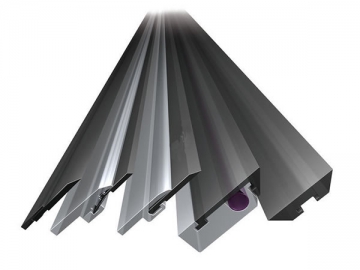

UHMWPE Forming Board

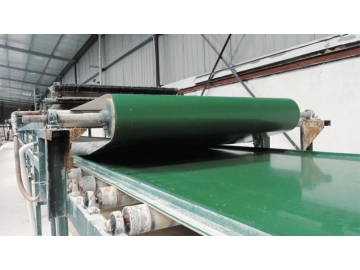

This UHMWPE drainage element is designed to serve various industrial applications. These UHMWPE forming boards are primarily used for paper industry purposes. UHMWPE machined parts are known for their wear resistance and ability to work well in moist environments. The high end engineered plastic component is cost effective and has a long working life.

Features of the UHMWPE Forming Board

1. Custom fitted to each machine

2. High inertial strength for vibration-free operation

3. 316L stainless steel external construction

4. Free discharge of doctored water

5. T-bar mounting provides the flexibility to control the cover opening without removing the fabric

6. Multiple T-bar positions are spaced to match table pulse frequencies

7. Horizontally and vertically adjustable custom designed mounts provided

8. Complete adjustability to accept jet impingement

Size

Any size can be customized

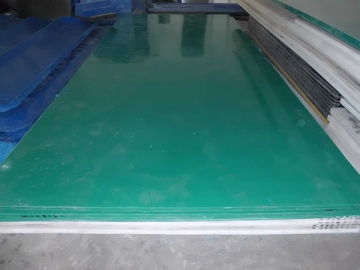

Color

White, yellow, blue, orange, green, etc.

Applications

The UHMWPE forming board is a collection of custom plastic parts specially designed to fit close to the breast roll nip in paper manufacturing machines. Its lead blade supports the fabric as it slices the material.

| Properties | Unit | Method | |

| Density | g/cm3 | 527 / D 792 | 0.93-1 |

| Tensile strength at yield | MPa | 527 / D 638 | 17 |

| Tensile strength at break | MPa | 527 / D 638 | 40 |

| Elongation at break | % | 527 / D 638 | >50 |

| Modulus of elasticity in tension | MPa | 527 / D 638 | 650 |

| Modulus of elasticity in flexure | MPa | 178 / D 790 | 800 |

| Ball indentation hardness | MPa | 2039/1 | 35 |

| Impact Strength | kJ/m2 | 179 / D 256 | No br. |

| Creep rupture strength after 1000 hrs with static load | MPa | ||

| Time yield limit for 1% elongation after 1000 hrs | MPa | ||

| Coefficient of friction against hardened and ground steel p=0,05 N/mm2, v = 0,6 m/s | - | 0.29 | |

| Wear conditions as above | um/km | ||

| Crystalline melting point | ℃ | DIN 53 736 | plus 135 |

| Glass transition temperature | ℃ | DIN 53 736 | |

| Heat distortion temperature Method A Method B | ℃ ℃ | R 75 R 75 | 42 ~70 |

| Max. service temperature short term long term | ℃ ℃ | plus 120 plus 90 | |

| Coefficient of thermal conductivity | W/(m K) | 0.41 | |

| Specific Heat | J/(g K) | 1.84 | |

| Coefficient of thermal expansion | 10-5/K | DIN 53 483 / D 696 | 20 |

| Dielectric constant at 105 Hz | DIN 53 483 | 3 | |

| Dielectric loss factor at 105 Hz | DIN 53 483 | ||

| Specific volume resistance | Ω cm | DIN 60093 | 1014 |

| Surface resistance | Ω | DIN 60093 | 1012 |

| Dielectric Strength1mm | kV/mm | ASTM 149 | 45 |

| Tracking Resistance | 53 480 | KA3c, KB>600, KC>600 | |

| Moisture absorption: Equilibrium in standard atmosphere (plus23℃/ 50% relative humidity) | % | 62 | 0.01 |

| Water absorption at saturation at plus23℃ | % | 62 | 0.01 |

| Resistance to hot water, washing soda | resistant | ||

| Flammability according to UL standard 94 | HB | ||

| Resistance to weathering | Natural: not resistant Black: resistant |