Cylinder Heated Drying Ironer

The cylinder heated drying ironer is a well designed laundry equipment for industrial applications. Available with three optional heating methods-steam heating, electric heating or gas heating, this commercial ironer integrates all the advantages of the steam ironer, electric ironer and gas ironer, providing customers with multiple solutions regarding heat sources, cost control, emission gas control, etc.

Features of Cylinder Heated Drying Ironer

1. Creating More Value for Customers

1) High Ironing Efficiency and Long Lifespan

High quality stainless steel cylinders are adopted for the machine to ensure its reliable performance, long life span, and high heat conduction efficiency, which enables the surface temperature to heat faster and significantly improves the ironing speed. The faster the ironer works, the more value it creates for owners.

2) Higher Ironing Speed

Unique wrap angle of up to 330°, the maximum wrap angle in the domestic market, is designed to achieve a larger contact area between the cylinder surface and the flatworks being ironed, which significantly speeds up the ironing process.

3) Stable Ironing Temperature and No Condensation

Independent steam trap and manual valve for each heating cylinder ensures almost 100% saturated steam inside the cylinder and no condensation, providing high and consistent surface temperatures and guaranteeing a reliable and quality ironing performance. This technology completely avoids problems with residual condensation which can result in the surface temperature dropping.

2. Comfortable Design Leading to Easy and Safe Operation

1) VFD System

VFD provides a variable speed throughout the entire speed range. The whole ironing process can be finished after only a simple push of the button. The operator can adjust the ironing speed for different textiles.All other processes are automatically done by the VFD system.

2) Ergonomic Design

The ergonomic design of this ironing machine caters to most operators. The 1.35m operating height ensures easy and labor-saving operation.

3) Safety Protection Design

This flatwork ironer is equipped with a safety switch which will automatically stop the machine in the event the finger safeguard board is pushed forward, protecting the operator's safety. A broad voltage design ensures high adaptability of the machine to circumstances where external voltage fluctuates. That is to say, in most cases, this drying ironer can work steadily despite unstable power supplies.

4) Gas or electric heating is available based upon your requirements.

3. Stable and Reliable Operation

1) High Resistance to Temperature

Nomex's high temperature ironing belts withstand high temperatures of up to 200°C, providing improved quality and a prolonged lifespan. Compared to traditional ironers with separation pins, LittleDuck's ironers are equipped with additional supporting roller, avoiding completely the wear and tear of ironing belts and extending the service life of the belts significantly.

2) High Rigidity and Stability

Heavy duty frame structure ensures high rigidity and long-term stable operation of the machine.

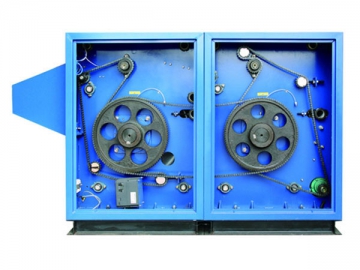

3) Precise Transmission Ratio and High Reliability

Chain transmission system of this cylinder heated ironer features stable driving with low noise and easy maintenance and repair. This chain driving has precise transmission ratios, long service life and high reliability. Premium rotary joints help increase the stability and reliability of the machine.

4) High Quality Feeding Rollers

All feeding rollers are made of seamless stainless steel tubes, credited for their low deformation and long service life compared with welded tubes. Zinc coating is applied to all pressure rollers to enhance their resistance to corrosion.

4. Gas Heating Mode Available

This gas heated ironer adopts a direct-fired infrared method for incomparably fast heating, low running cost, low emission output and pollution-free operation.

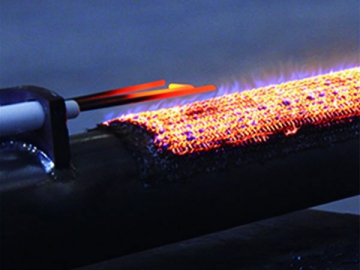

1) Direct-fired Metal Fiber Burner

LittleDuck's LPG natural gas ironer utilizes a direct-fired metal fiber burner to generate high temperature infrared heat. Air heated by the infrared energy will then directly heat the ironer's cylinder. This direct-fired infrared system is designed to work automatically under the control of the computer board.

Features: A metal-fiber burner is anti-corrosive, oxidation-resistance and resistant to impact, which all ensure the long service life of the burner. Carbon deposits won't happen because of the high surface temperature of the metal-fiber burner. Therefore no additional cleaning and maintenance is required.

2) Automatic Ignition and Flameout

The automatic ignition and flameout are achieved through the installation of the temperature sensor which makes easy operation possible. The gas system consists of a flame detecting device, flameout protection device and failure alarm device which all together ensure the safe operation of the machine.

- Gas Burner for the Gas-heated Ironer

- Bottled LPG (Optional)

5. Standard Features of the Cylinder Heated Drying Ironer

1. Computer-controlled system for easy operation;

2. Stainless steel drying cylinder ensuring high heat-transmission efficiency and long service life;

3. Adjustable speed control meets the ironing requirements of different textiles;

4. Maximum wrap angle of up to 330° gives the best ironing effect;

5. Independent steam trap for each cylinder significantly promotes the heat transmission and ironing speed;

6. Premium rotary joints ensure stable and reliable operation;

7. Chain transmission guarantees reliable operation and low noise;

8. Heavy duty frame design provides stable running;

9. Feeding rollers made of seamless tubes, ensure little deformation and long service life;

10. Broad voltage design ( /-10%) provides a wide application range;

11. Finger safeguard board with safety switch protects operators;

12.1.35m operating height for easy operation;

13. Steam heating available for customers.

6 Optional Designs for Cylinder Heated Drying Ironer

1) Electrical heating

2) Gas heating

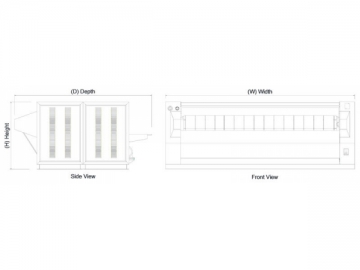

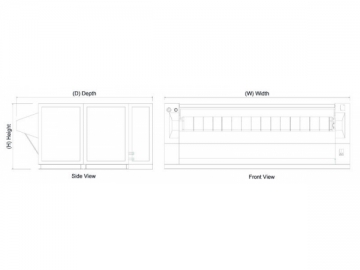

Technical Specifications of the Cylinder Heated Drying Ironer

1. Steam Heating Type

| Ironer Type | Single-cylinder | Double-cylinder | Triple-cylinder | ||||

| Heating Type | steam | steam | steam | steam | steam | steam | |

| Model No. | Unit | ||||||

| CYLINDER | |||||||

| Max. Ironing Width | mm | 3000 | 3300 | 3000 | 3300 | 3000 | 3300 |

| Ironing Speed | m/min | ≤12 | ≤ 12 | ≤24 | ≤24 | ≤30 | ≤30 |

| Cylinder Diameter | mm | 800 | 800 | 800 | 800 | 800 | 800 |

| STEAM | |||||||

| Steam Pressure | Mpa | ≤0.7 | ≤ 0.7 | ≤0.7 | ≤0.7 | ≤0.7 | ≤0.7 |

| Steam Consumption | kg/h | ≤95 | ≤ 100 | ≤190 | ≤210 | ≤285 | ≤300 |

| Steam Inlet | DN, mm | 50 | 50 | 50 | 50 | 50 | 50 |

| Drainage Outlet | DN, mm | 25 | 25 | 25 | 25 | 25 | 25 |

| POWER | |||||||

| AC Voltage | V | 380/415V | 380/415V | 380/415V | 380/415V | 380/415V | 380/415V |

| Line Frequency | Hz | 50 | 50 | 50 | 50 | 50 | 50 |

| Phase | P | 3 | 3 | 3 | 3 | 3 | 3 |

| Motor Power | kW | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| DIMENSION | |||||||

| Width | mm | 3800 | 4100 | 3800 | 4100 | 3800 | 4100 |

| Depth | mm | 1920 | 1920 | 2845 | 2845 | 3770 | 3770 |

| Height | mm | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 |

| Net Weight | kg | 1600 | 1700 | 3200 | 3300 | 4800 | 5000 |

2. Electric Heating Type

| Ironer Type | Single-cylinder | Double-cylinder | |||

| Heating Type | Electrical | Electrical | Electrical | Electrical | |

| Model No. | Unit | ||||

| CYLINDER | |||||

| Max. Ironing Width | mm | 2800 | 3000 | 2800 | 3000 |

| Ironing Speed | m/min | ≤10 | ≤10 | ≤20 | ≤20 |

| Cylinder Diameter | mm | 800 | 800 | 800 | 800 |

| POWER | |||||

| AC Voltage | V | 380/415V | 380/415V | 380/415V | 380/415V |

| Line Frequency | Hz | 50 | 50 | 50 | 50 |

| Phase | P | 3 | 3 | 3 | 3 |

| Motor Power | kW | 0.75 | 0.75 | 1.5 | 1.5 |

| Electrical Heater Power | kW | 36 | 36 | 72 | 72 |

| DIMENSION | |||||

| Width | mm | 3600 | 3800 | 3600 | 3800 |

| Depth | mm | 1920 | 1920 | 2845 | 2845 |

| Height | mm | 1350 | 1350 | 1350 | 1350 |

| Net Weight | kg | 1400 | 1500 | 2900 | 3100 |

3. Gas Heating Type

| Model No. | Unit | ||||

| CILINDER | single-cylinder | single-cylinder | double-cylinder | double-cylinder | |

| Heating Type | Gas | Gas | Gas | Gas | |

| CAPACITY | |||||

| Max. Ironing Width | mm | 3000 | 3300 | 3000 | 3300 |

| Ironing Speed | m/min | ≤ 12 | ≤ 12 | ≤ 24 | ≤ 24 |

| Cylinder Quantity | pc | 1 | 1 | 2 | 2 |

| Cylinder Diameter | mm | 800 | 800 | 800 | 800 |

| POWER | |||||

| AC Voltage | V | 380/415V | 380/415V | 380/415V | 380/415V |

| Line Frequency | Hz | 50 | 50 | 50 | 50 |

| Phase | Ph | 3 | 3 | 3 | 3 |

| Motor Power | kW | 0.75 | 1.5 | 1.5 | 1.5 |

| GAS | |||||

| LPG=Liquefied Petroleum Gas | LPG can use pipelined gas or bottled gas | ||||

| NG=Natural Gas | NG can use pipelined gas or bottled gas | ||||

| Calorific Value - LPG/NG | Kcal/Kg | 10813~11028Kcal/Kg | |||

| Gas Pressure | Mpa | 0.2~0.28 | 0.2~0.28 | 0.2~0.28 | 0.2~0.28 |

| Gas Consumption | kg/h | 5 | 5.5 | 10 | 11 |

| DIMENSION | |||||

| Width | mm | 3800 | 4100 | 3800 | 4100 |

| Depth | mm | 1920 | 1920 | 2845 | 2845 |

| Height | mm | 1350 | 1350 | 1350 | 1350 |

| Net Weight | kg | 1600 | 1700 | 3200 | 3300 |