Wet Wire Drawing Machine (21 Drawing Dies)

Our wet wire drawing machine with 21 drawing dies is specially designed to draw steel wires for steel cords. The diameter of steel wires before drawing can be between 0.8-1.9mm. After being drawn by this slip drawing machine, the diameter is reduced to 0.15-0.35mm. Steel wires drawn by the wet drawing machine are ideal for making electric wires, cables, and steel cords, and thus the wet drawing machine often serves as a key part for complete cable production lines, steel cord production lines, etc.

Features of the 21 Die Wet Wire Drawing Machine

1. The main frame of this wire drawing equipment is welded and an aging treatment applied.

2. Spindle adopts SKF bearings while other shafts use NSK bearings.

3. Due to the wire guide roller allowing for an adjustable wire feeding angle, the steel wire drawing machine reduces wire scratching.

4. Floor take-up stands are used for spools with a diameter of more than 300mm. Aging treatment reduces the stand's vibration.

5. Synchronous pulleys with a diameter of less than 150mm will receive heat treatment, ensuring a high surface hardness of HRC27-28.

6. The water tank of the wet wire drawing machine is designed with a stainless steel enclosure which reduces the amount of heat discharged from lubricating liquid.

7. This wire drawing system applies a three-point adjusting device to adjust the diameter of the steel wire coil diameter, one point for fixing and two points for adjusting.

8. The PLC control system has an automatic wire fracture protection function.

9. The wire drawing machine displays a series of parameters including product specifications, take-up speed, take-up length, lubricating liquid temperature, running time, etc.

10. Meter counting precision of less than 1‰ and correction factor ensures consistent length accuracy.

12. Energy saving and efficient motor is used.

| Inlet wire diameter | 0.8-1.9mm |

| Finished wire diameter | 0.15-0.35mm |

| No. of wire drawing die | 21 |

| Drawing speed | Max.18m/s |

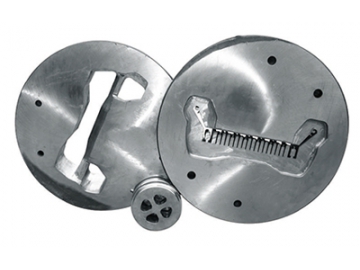

| Step pulley structure | Split type four step pulleys; diameter: ±0.5mm |

| Payoff spools | Basic φ800 spool (Size can be customized as needed) |

| Pay-off method | Pneumatic pay-off (passive), with tension and air pressure adjustment |

| Take-up braking device | Pneumatic brake |

| Main motor | AC Variable frequency motor, 22 or 30Kw |

| Electrical control mode | PLC control, multifunctional automatic protection |

| Step pulley surface condition | Coated with WC; HRC60-62; 1.5 years warranty |

| Die size | φ28×15 |

| Lubrication and cooling method | Submerged lubrication and circulation cooling |

| Lubrication box capacity | 750L |