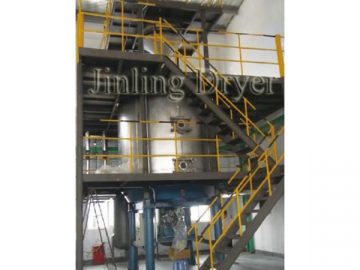

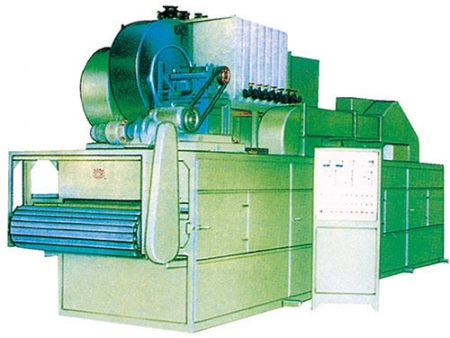

Hot Plate Dryer

In the PGC hot plate dryer, wet raw materials are fed continuously to the first hot plate on the top of the dryer. Raw materials are then turned and agitated via the rotating rake. Raw material on the small hot plate will move to the plate's outer edge and drop down to the outer edge of the large hot plate underneath, then will move inward and drop down a central hole to another small hot plate on the lower layer. Both small and large drying plates are arranged alternately so that raw material can go through the whole dryer continuously. The dried product will drop from the lowest layer of the hot plate to the bottom layer of the chamber body and rakes will move it to be dispensed from the plate dryer. Any moisture is removed from an exhaust vent at the top of the chamber, or is sucked out by a vacuum pump (only for vacuum hot plate dryers).

This versatile drying equipment can use hot water, steam or thermal oil as a heat source as well as chilled water for cooling.

Advantages of the Hot Plate Dryer

1. Easy production operation, good adaptability.

(1) User can obtain the best drying effect by adjusting the thickness of the raw material pavement, shaft rotating speed, quantity and form of rakes.

(2) Each layer of hot plates can be filled with a heating or cooling medium for drying or cooling.

(3) Retention time of material can be accurately controlled.

2. Convenient operation

(1) Operation panel is simple to use.

(2) Dispensing of product finishes soon after feeding stops.

(3) Inspect the whole drying or washing process via the vacuum dryer's observation window.

3. Low energy consumption

(1) The motor of the dryer consumes little power.

(2) Dries through indirect heating for high efficiency.

4. User-friendly operation of cooling unit, solvent can be recovered.

(1) Air speed and air volume in drying chamber is low so powder is barely blown up.

(2) There is a wide range of moisture content between the bottom hot plate layer and the top hot plate layer. Dried powder on the bottom layers is far from the exhaust vent; wet material on the top layers have a large bulk density.

5. High drying efficiency

The plate dryer's fixed disk is designed with a jacket which can be filled with liquid or steam to transfer heat and carry out cooling processes. Material will fall from the upper disk layer to the lower disk layer, speeding up the drying or cooling rate. (If your heat source is steam, please indicate so in your order of the PGC plate dryer.)

Technical Parameters of the Hot Plate Dryer

| Model | Outer diameter (mm) | Height (mm) | Drying area (m2) | Power (kw) |

| 1850 | 2608 | 3.3 | 1.1 | |

| 3028 | 4.9 | |||

| 3448 | 6.6 | 1.5 | ||

| 3868 | 8.2 | |||

| 4288 | 9.9 | |||

| 2900 | 3262 | 18.5 | 3.0 | |

| 3682 | 24.6 | |||

| 4102 | 30.8 | |||

| 4522 | 36.9 | |||

| 4942 | 43.1 | |||

| 5362 | 49.3 | |||

| 2900 | 5782 | 55.4 | 5.5 | |

| 6202 | 61.6 | |||

| 6622 | 67.7 | 7.5 | ||

| 7042 | 73.9 | |||

| 7462 | 80.0 | |||

| 3800 | 4050 | 48 | 11 | |

| 4650 | 60 | |||

| 5250 | 72 | |||

| 5850 | 84 | |||

| 6450 | 96 | |||

| 7050 | 108 |