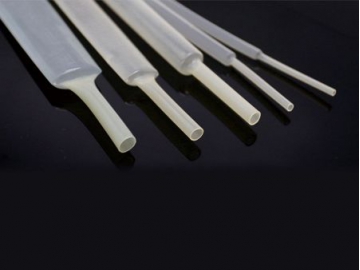

Clear PVDF Tubing

Request a Quote

CYG-KYNAR (150/175)

Flame-Retardant Heat Shrink Tubing for Electronic Applications

- Irradiation cross-linked modified fluoropolymer

- Shrink Ratio: 2:1

- High-temperature resistance, transparency, and flame-retardancy

- Flexible (-55°C to 150°C) and semi-rigid (-55°C to 175°C)

- Shrink temperature: 150°C (flexible), 175°C (semi-rigid)

Applications

- This product offers ideal heat resistance, abrasion resistance, resistance to mechanical damage, and resistance to chemical substances, making it suitable for environments with corrosive air, thermal cycling, or mechanical stress.

- It exhibits superior flame-retardant properties and is commonly used in applications such as automotive, aviation, marine, and electronic equipment wiring.

- Furthermore, its transparency is ideal for encapsulation and distinguishing of electronic components.

Features

- Shrink Ratio: 2:1

- High-temperature resistance, transparency, and flame-retardancy

- Flexible (-55°C to 150°C) and semi-rigid (-55°C to 175°C)

- Shrink temperature: 150°C (flexible), 175°C (semi-rigid)

- Flexible type certified to UL150°C/600V (Certification No.: E180908)

- Semi-rigid type meets SAE-AMS-DTL23053/8 standard requirements

- Standard color: Clear

| Properties | Test Method | Performance 150℃ (flexible) | Performance 175℃ (semi-rigid) |

| Specific gravity | ASTMD792 | ≤1.8g/cm³ | ≤1.8g/cm³ |

| Tensile strength | ASTMD2671 | ≥24.5MPa | ≥34.5MPa |

| Ultimate elongation | ASTMD2671 | ≥150% | ≥150% |

| Ultimate elongation after aging | 225℃ (flexible), 250℃ (semi-rigid)/168h | ≥100% | ≥50% |

| Heat shock | 275℃ (flexible), 300℃ (semi-rigid)/4h | No flowing, no cracking | No flowing, no cracking |

| Cold bend | -55℃/4h | No cracking | No cracking |

| Dielectric strength | ASTMD2671 | ≥15.7kV/mm | ≥31.5kV/mm |

| Volume resistivity | ASTMD257 | ≥1.0×1013 Ω·cm | ≥1.0×1013 Ω·cm |

| Flammability | UL224 | Pass VW-1 | Pass VW-1 |

Shrink Ratio: 2:1

| Size | Inside Diameter (mm) | Wall Thickness After Recovery (mm) | Length (m) | |

| As Supplied (Min.) | After Recovery (Max.) | |||

| Ø1.2 | 1.2 | 0.6 | 0.25±0.05 | 200 |

| Ø1.6 | 1.6 | 0.8 | 0.25±0.05 | 200 |

| Ø2.4 | 2.4 | 1.2 | 0.25±0.05 | 200 |

| Ø3.2 | 3.2 | 1.6 | 0.25±0.05 | 200 |

| Ø4.8 | 4.8 | 2.4 | 0.30±0.05 | 100 |

| Ø6.4 | 6.4 | 3.2 | 0.33±0.05 | 100 |

| Ø9.5 | 9.5 | 4.8 | 0.33±0.05 | 100 |

| Ø12.7 | 12.7 | 6.4 | 0.33±0.05 | 100 |

| Ø19.1 | 19.1 | 9.5 | 0.43±0.08 | 50 |

| Ø25.4 | 25.4 | 12.7 | 0.48±0.08 | 50 |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos