Precision Forging Press for Ball Valves

JIASHENG established a cooperative relation with Taiyuan University of Science and Technology and Metal Forging and Controlling Laboratory, and designed this precision forging press for ball valves. After being launched on the market, this kind of precision forging press sells well and is applied in many places, especially the producing of ball valves and pipes. Our precision forging press has won much trust from customers due to many attractive features, like high working efficiency, high utilization of raw materials, low labor cost and high precision.

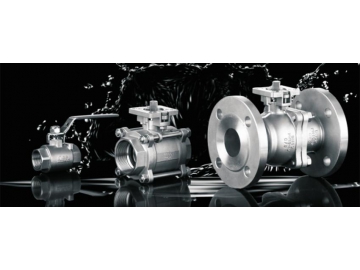

Shown here is our precision forging press for ball valves.

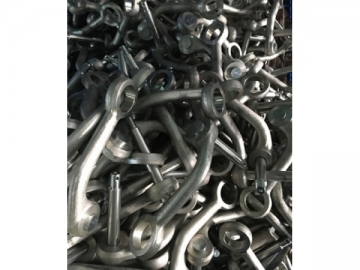

Every day, countless ball valves are forged by our hydraulic press and applied in a variety of fields.

Outstanding Advantages 1. The applied flexible control system is well known for its capacity in producing products of required specifications as well as achieving an effective and close connection between each part.

2. The closed die forging technique saves a lot of raw materials and realizes an increase of 15%-45% in material utilization.

3. Our precision forging press cuts lots of finish processing time as well as valuable manpower.

4. An integrated forging design greatly shortens processing procedures and saves operating cost.

5. This forging press ensures precise forging in a direct and fast fashion, with short manufacturing time, high producing efficiency and abundant economic benefits.

6. A long and smooth guide rail ensures the forging precision of components.

7. Ball valves processed by our forging press possess a high quality density and good impact resistance.

8. Our press finds extensive application in the finish forging and molding of ball valves and pipes.

9. It also meets the requirements and standards of finish forging of common carbon steel and stainless steel.

Technical Data

| Item | Unit | | | |

| Nominal molding force | KN | 3150 | 4000 | 5000 |

| Nominal back pressure | KN | 3150 | 4000 | 5000 |

| Nominal extrusion force | KN | / | / | / |

| Max stroke | mm | 250 | 300 | 300 |

| Stroke of back pressure | mm | 250 | 300 | 300 |

| Extrusion stroke | mm | / | / | / |

| System pressure | MPa | 25 | 25 | 25 |

| Molding speed | mm/s | 30-60 | 30-60 | 30-50 |

| Speed of empty trip | mm/s | 260-330 | 260-330 | 260-330 |

| Speed of return trip | mm/s | 230-270 | 230-270 | 220-270 |

| Molding efficiency | s.p.m | 9-12 | 8-12 | 7-10 |

| Workpiece weight | KG | 1.8 | 2.3 | 2.5 |

| Installed power | KW | 100 | 123 | 151 |

| Item | Unit | | | | |

| Nominal molding force | KN | 6300 | 8000 | 4000 | 5000 |

| Nominal back pressure | KN | 6300 | 8000 | 4000 | 5000 |

| Nominal extrusion force | KN | / | / | 2000 | 3150 |

| Max stroke | mm | 400 | 400 | 300 | 300 |

| Stroke of back pressure | mm | 400 | 400 | 300 | 300 |

| Extrusion stroke | mm | / | / | 150 | 150 |

| System pressure | MPa | 25 | 25 | 25 | 25 |

| Molding speed | mm/s | 25-50 | 25-45 | 30-40 | 30-40 |

| Speed of empty trip | mm/s | 260-320 | 260-320 | 260-330 | 260-330 |

| Speed of return trip | mm/s | 200-250 | 200-250 | 230-270 | 250-270 |

| Molding efficiency | s.p.m | 7-10 | 6-9 | 8-12 | 7-10 |

| Workpiece weight | KG | 3.2 | 3.5 | 2.2 | 2.4 |

| Installed power | KW | 183 | 197 | 123 | 151 |