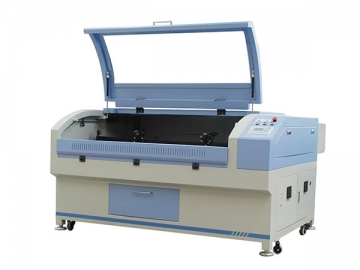

CM Series CO2 Laser Cutting and Engraving Machine

CO2 Laser Cutting and Engraving Machine / Laser Cutting and Engraving Machine / Laser Carving Machine

The CM series CO2 laser machine offers economical solutions for general purpose and high quality cutting and engraving on acrylics, cardboard, wood, textiles, color plates, stones and other materials.

Models and Tech Specs| Model | ||

| Working Area | 51" x 35" / 1300 x 900mm | 63" x 39" / 1600 x 1000mm |

| Z-Axis | 8" / 210mm | N/A |

| Motion System | Servo Motor / High Quality Step Motor | |

| Resolution | 4000DPI | |

| Laser Source | Glass CO2 Laser | RF Metal CO2 Laser |

| Configuration and Wattage | Single or Dual 100W/130W/150W | Single 50W/100W |

Main Configurations Introduction

Most Profitable and Multi-Purpose Working Area

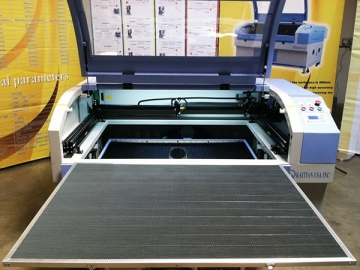

The CM-1309 has a working area of 51" x 35" x 8" (1300mm x 900m x 210mm) in an X Y Z dimension. The CM-1610 has a working area of 63" x 39" (1600mm x 39mm) in an X Y dimension. With an easily opened front door and back component, the CM series laser cutting machine has a rear pass through functionality. Users can easily process long work pieces, and feature a better dust exhaust result by closing the front door and back components when processing a work piece inside the working area. We provide a honeycomb table for soft material processing (materials such as paper and textiles) in order to get better overall support. The aluminum strip table on the other hand is used for hard and non-flammable material processing for materials such as acrylic, cardboard and wood, in order to avoid laser reflection and garner a clean cutting edge. The working table on the CM-1309 moves up and down using a motor drive in order to hold work pieces in abnormal shapes or U units for rotary processing.

Deep Collecting Bay and Pick Up Drawer

After processing, small parts and parts without a supporting strip under them drop down into the deep collecting bay to avoid interaction with the laser. Users can easily remove them by pulling out the drawer.

High Performance Motion System

Using a servo motor from internationally known suppliers, the CM series moves quickly at an extremely high resolution with a step length of 6.35μm (4000DPI), and an acceleration of 0.2G for cutting, and 2G for engraving. Users can also choose a more economical model with a high quality step motor without sacrificing performance.

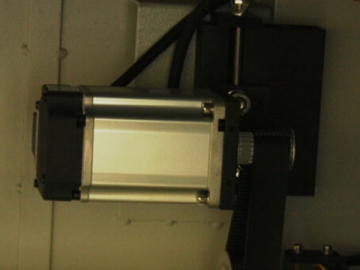

U Unit for Rotary Cutting and Engraving

Due to the Z-axis movable working table, the CM-1309 laser engraving machine can be equipped with an optional U unit for rotary processing.

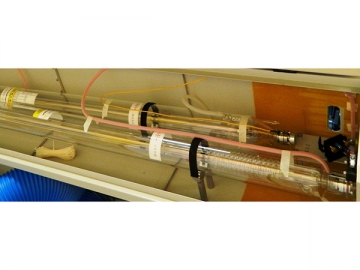

Laser Source

The CM series laser cutting machine can be equipped with a single or dual 100W, 130W, or 150W glass CO2 laser tubes with an outstanding cost performance ratio according to your needs. Users can use either one or both at the same time by pressing the laser power enable button on the control panel.

Our 150W laser can cut acrylic up to 1-1/8" (30mm), which is the best available on the market.

If users do a lot of engraving and want to be more productive, we recommend the 50W/100W RF metal tube. Users will get more jobs done, and faster, without sacrificing processing quality.

Industrial Chiller

The CM series laser is equipped with a high quality industrial chiller to ensure the continuous and stable output of the laser.

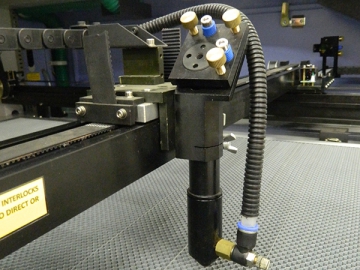

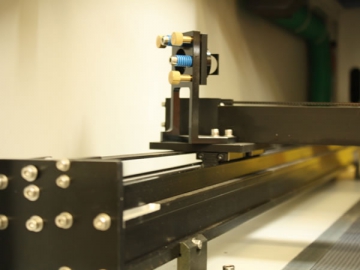

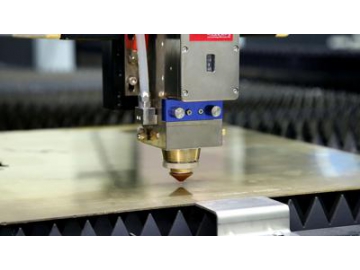

Laser Head

The CM series laser cutting and engraving machine can be equipped with a single or dual heads according to laser configurations. Users can easily adjust the space between the two heads.

Our laser head has 2 installation positions for the focus lens, with the same focusing space between the nozzle and the workpiece. The lower position if for 2.5" and general purpose processing. The upper position is for 4" and cutting purposes.

The reflection mirror adjustment is designed to be stable and easy to use. With 3 adjustment screws, it is easy to align in any condition.

The laser engraving machine is also equipped with an air assist assembly with a flow adjustment on the laser head. By directing a steady stream of compressed air across the cutting surface, the possibility of flaming, scorching or charring is reduced when cutting materials such as acrylic or wood.

High Quality Optics

Our CM series laser engraving machines are equipped with optics produced in America in order to produce a high quality and consistent laser beam across the entire working area. This achieves a better cutting and engraving quality.

Visual Control System

This series of laser cutting and engraving machines is equipped with a high performance control system featuring a user friendly visual UI panel. By embedding flash storage in the controller, users can transfer jobs through a USB drive, Ethernet, or flash disk, then finish the processing offline without relying on a computer connection. With a true color TFT LCD panel, users can also preview machine status and job details before processing, such as the current position of the laser head, connection status, graphic detail, processing parameters and estimated processing time. Users can also adjust the parameters for different materials, as well as run a processing simulation on the panel. The control system will save all changes made for future use. While processing, users will receive real time processing information on the panel, and can adjust parameters on the fly according to actual results. In the event of power failure or mistakes, users can recover the job.

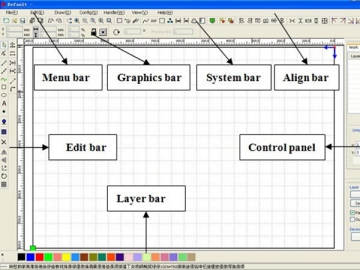

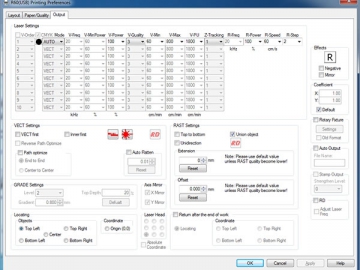

Software and Print Driver

Uses can import or create a new design, finish layout and sorting, run a processing simulation and directly control the machine using our software.

With the user friendly print driver, users can also use their favorite applications, such as CorelDRAW, Photoshop, or AutoCAD to transfer a job to the machine through a few simple clicks.

With layers and a color mapping function, users can assign different processing parameters for different colors in a design. There is no need to run separate jobs for one project, and processing is faster with a more precise laser control.

Exhaust Blower

We provide a ready to use laser cutting and engraving machine package with all necessary parts, including the exhaust blower. Simply set up the machine and start the project.

Safety and Reliability

The CM series is designed, engineered and built with safety and reliability in mind. We use electronic parts from internationally known suppliers and build a system to meet international standards. There are numerous sensors around the machine, such as an open door sensor, open laser tube box sensors, laser cooling water pressure sensor and more. The machine will stop automatically if something unsafe occurs. When this happens, users must shut down the machine immediately and completely by pressing the easy to reach emergency stop button on the panel.

Applications