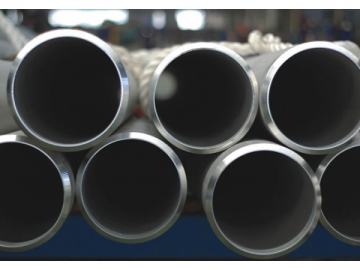

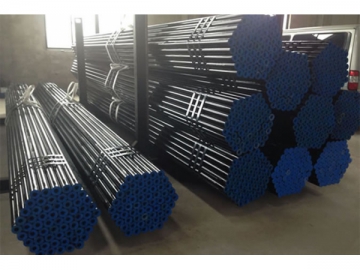

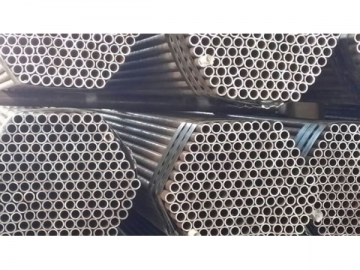

Cold Drawn Seamless Steel Tube

Manufacturing process

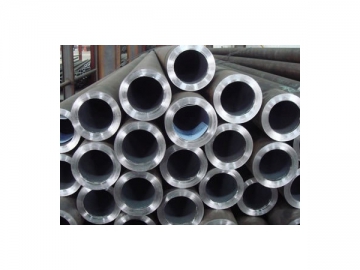

We manufacture the cold drawn steel pipe by the following process. Steel billet → heating → punching → head making → annealing → pickling → copper plating → cold drawing → semi-finished pipes → heat treatment → straightening → Hydraulic test →UT → labeling → warehouse entry.

OD:10.3mm--114mm (1/8"-4")

WT: 1.5mm-4mm

Standard:

API Spec 5L Standard Specification for line pipe

ISO 3183 Petroleum and natural gas industries-Steel pipe for pipeline transportation systems

ASTM A 53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A106 Standard Seamless Carbon Steel Pipes for oil pipeline and gas pipeline transportation

ASTM A333 Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service

ASTM A519 Seamless Carbon and Alloy Steel Mechanical Tubing

ASTM A192 Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service

ASTM A210 Standard Specification for Seamless Medium-Carbon Steel Boiler and Super heater Tubes

ASTM A179 Seamless Cold-Drawn Low-Carbon Steel Heat-Ex changer and Condenser Tubes

EN10216 Seamless steel tubes for pressure purposes

EN10297 Seamless circular steel tubes for mechanical and general engineering purposes

EN10305 Steel tubes for precision applications. Technical delivery conditions. Seamless cold drawn tubes

EN 10210: Seamless structural steel pipes

DIN1629 Seamless circular unalloyed steel tubes subject to special requirements

DIN2391 Precision cold drawn seamless steel tube

DIN17175 Seamless tubes of heat-resistant steels

DIN 2391 Seamless Precision Steel Tubes

JIS G3441 Alloy steel tubes for machine purposes

JIS G3444 Carbon steel pipes for general structural purposes

JIS G3445 Carbon steel tubes for machine structural purposes

Material Grade:

API5L Gr. B /X 42 / X52 / X56 / X60 / X 65 / X 70

A-53Gr. A/B/C, A-106Gr. B/C Grade A, Grade B, Grade C, Type F, Type E

A-333Gr. 1. 3. 4. 6. 7. 8. 9. 10. 11

A519 MT 1010, MT 1015, MT1020, MTX 1020,

1008, 1010, 1012, 1015...1026, 1030, 1035, 1040, 1045, 1050, 1518, 1524, 1541,

SA-192, SA-210, SA-179,

P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, T265TR2, P195GH, P235GH, P265GH

E235, E275, E315, E355a, E470, C22E, C35E, C45E, C60E, 38Mn6

S235JRH, S275JOH, S355JOH, S355J2H, S355K2H

ST37.0, ST44.0, ST55, ST52.0, CK45

ST35.2, ST45.2, ST55.2, ST52

STPG 370, STPG 410, STS 370, STS410, STPT 370, STPT 410/480

Length: Random Length, Fixed Length, SRL

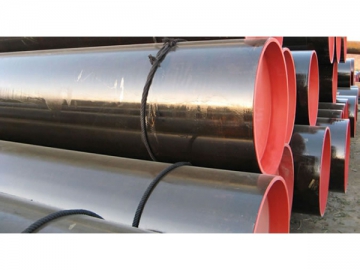

Surface Treatment: Oil Varnish, black anti-rust paint, hot-dip galvanized, 3PE, 2PP, 2PE, FBE, etc

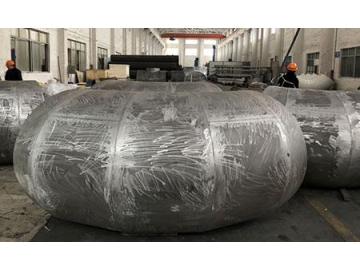

Packing: Sea package, woven bags, plastic end, in bundled with lifting belts

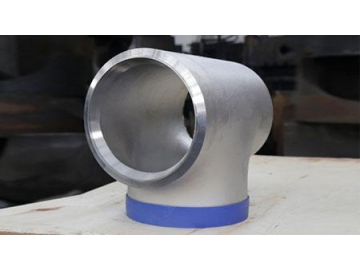

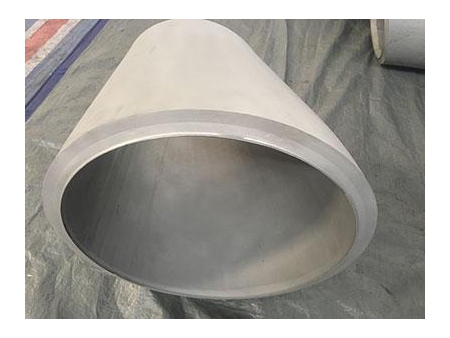

Ends Design: Beveled, Plain, Threaded with coupling, Grooved, Square cutted

Special Design :available according to customers’ requirement

Quality Guarantee: SGS, BV, Lloyd's, DNV, Moody, etc.

Cooperative Partner: Tianjin Pipe Group Corporation(TPCO), Shougang Group, Baosteel Group, Han-Steel Group, Hengyang Valin Steel Tube Co., Ltd(HYST) and Etc

Project: Oil and Natural Gas pipeline: Water Conveyance Pipeline, Airport Construction, Railway station Bridge Construction: Power Project and Etc More details Please see the Project Part.