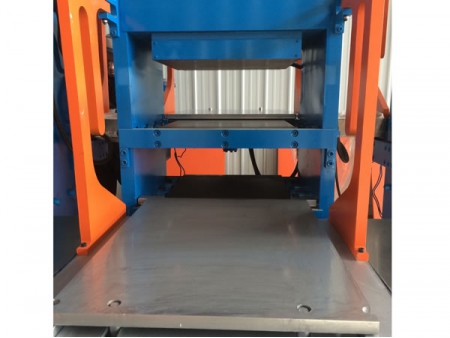

Fully Automatic Rubber Soles Compression Molding Machine

Request a Quote

Rubber Shoe Soles Molding Press, Rubber Shoes Machine, Rubber Soles Molding Press, Rubber Soles Machine

Operation Design

- One operator can handle multiple stations to minimize operating costs.

- Auto sliding devices at moving mold plates make operation easy.

- Auto inter-lock protection system for two-side simultaneous operation.

- Mold change is simple and fast just by fixing the bottom mold plate at the sliding seat.

- Every station is fit with an independent operating control. Each station can be switched on/of according to production or maintenance schedules.

- Auto sliding in/out and inside-tuming design for molds

High Productivity

Every station has two molds with two-side operation

Mold For Production

- Traditional hot-compressed rubber molds can be utilized on the machine.

- Clamping system is with direct hydraulic press; molds with different height can be adopted directly.

- Automatic sliding devices for mold opening / closing is equipped to avoid mold damage caused by collision and to minimize cost of operation.

Plate Vulcanizing Press

Machine Form: Column or Frame

Technical Parameters- Type: XLB-DQ450x450MM

- Total pressure: 1.50MN

- Plate size: 450x450mm

- Plate clearance: 180MM

- Working layer number: 2

- Piston stroke: 360mm

- Piston diameter:300mm

- Electric heated platens

- Rough degree of hot plate surface : Ra ≤ 1.6 μ m (surface finish)

- Material: #45 grade steel (1045)

- Platen is one piece plate steel (no welding)

- Piston (ram) hardness : 68-72 Shore C

- Electric: Siemens and Schneider

- Working Temperature: 180 –200

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos