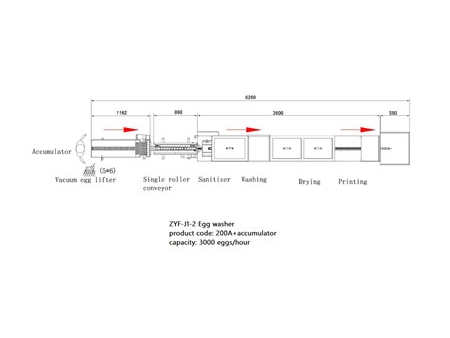

200A Egg Washer (3,000 EGGS/HOUR)

The ZENYER 200A egg washer has the capability of processing 3000 dirty eggs in one hour and can also be attached with a ZENYER or , for a higher production efficiency assembly line.

This machine works efficiently and enables simple operation. Only 2 workers are required (one for loading and candling while the other for collection), this egg cleanser is perfectly suited for small-sized cage-free farms.

| Product name | Egg cleaning machine |

| Product code | 200A |

| Model | ZYX-J1-2 |

| Capacity | 3,000 eggs/hour |

| Material | Stainless steel |

| Power* | 5.8 KW |

| Voltage* | 220V, 50HZ, single phase or 380V, 50HZ, three phase |

| Dimension(L×W×H) | 4.6*0.6*1.55M |

| Net weight* | 350KG |

| Gross weight* | 550KG |

| Function | Ramp loading, candler, sanitizer sprayer, brush washing, drying, manual collection table, optional egg printer, accumulator and vacuum egg lifter |

Notes

* Power, net weight and gross weight are calculated according to the floor plan above.

* The voltage and frequency may be different due to different countries. For more details of electrical data sheet, please check with the ZENYER representatives.

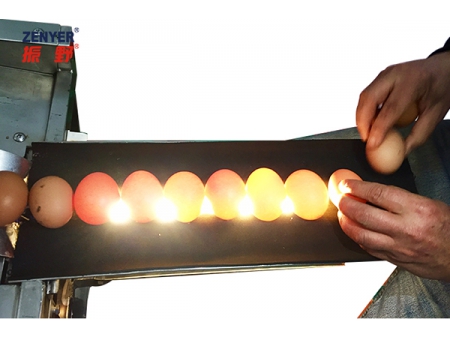

- Manual loading & candling

- Accumulator (optional)

- Sanitizer

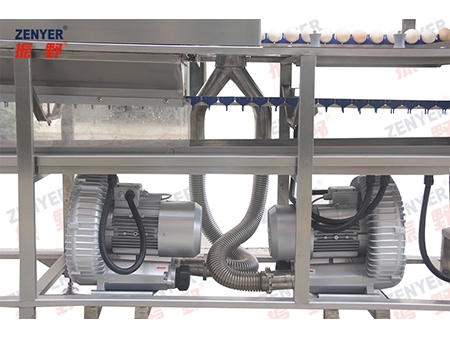

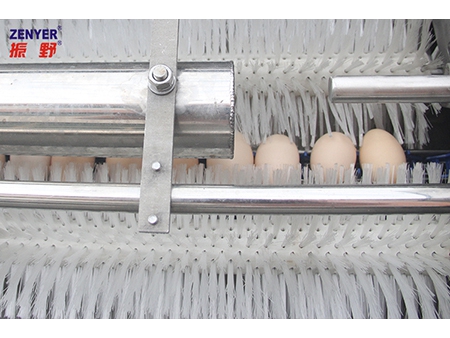

- Washing

- Drying

- Printing

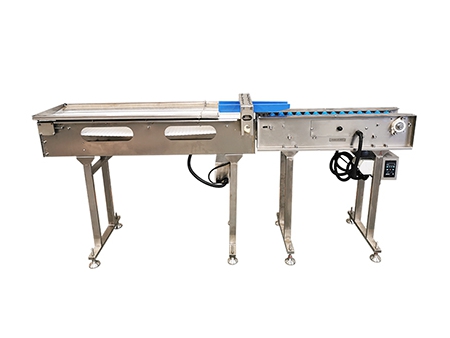

- Manual collection

Workers place eggs on the loading ramp.

Eggs will run through LED lights for candling purposes before dropping into the egg washer, meaning workers can easily pick out any unqualified eggs such as leaking or cracked ones.

Eggs are vacuum lifted and loaded onto the accumulator (with the single roller conveyor) using the 602 vacuum egg lifter. Through the accumulator, the eggs are separated into one row and transferred into the feeding unit of 200A egg washer.

Sanitizer sprayer sprays chemical liquid (such as sanitizer, detergent depending on the local government policy) on eggs automatically before washing.

- Before washing

- After washing

Eggs are effectively cleaned by brushes with warm water spraying (the machine doesn’t come with a water heater, customer provides it). Brush modules are flexible, and adjustments can be made on brush distance, position and speed.

Eggs are perfectly dried by dry brush and strong air.

could be attached at the end of the egg washer, you can print your farm name, logo, date, best before date, etc. on eggs.

Washed eggs will roll onto the collection table and can be placed into trays manually.