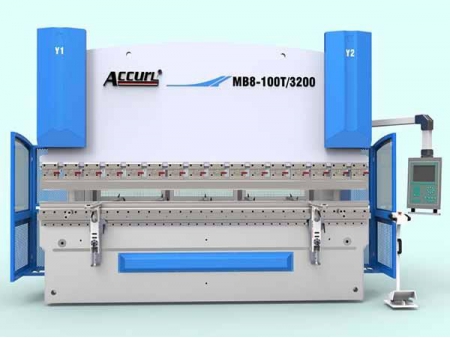

ACCURL-Bend - 6 Axes CNC Press Brake

Your new future trend

Production time is the most important factor in maximising profit in enterprises.

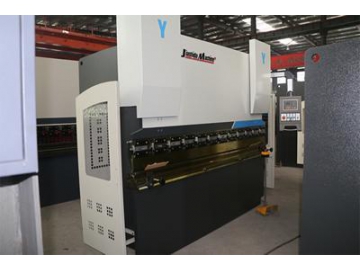

Speed-Bend series is designed to enable speed and high quality production capability in order to decrease time per unit costs.

Impressive bending solutions

Equipment/options can be tailored to individual request. Thus, the best productivity for each client is achieved while bending.

Extreme production with high performance in less time

1. Free-fall, bending and return speeds of Speed-Bend CNC press brakes series makes is the best choice to meet demands in today's competitive markets.

2. Speed-Bend series CNC press brake offer twice as fast production capacity compared to conventional CNC press brakes.

3. While increasing the speed, engineers of ACCURL R&D did not forget to increase the stroke and opening (daylight) for an ever more versatile press brake.

4. With these specs, deep bends can be achieved with longer tools, parts can be easily taken out from front of the machine.

5. Z-type parts can be bent with long dies.

"High-speed free fall"

"High pressing speed"

"High returning speed"

Servo motorized back gauge X R Z1 Z2 (standard)

1. CNC backgauge designed by ACCURL is fast and accurate. The strong construction ensures an efficient operation for many years.

2. The system moves with servo motor driven ball screw shafts and on linear bearings with an accuracy of 0.01.

3. The backgauge of CNC press brake can be upgraded with X1, X2, Z1, Z2, R1 and R2 on your request.

Shift to Speed-Bend If you are looking for speed, versatility and high efficiency, Speed-Bend press brakes are the right choice

1. High quality and repetitive bending is obtained by using synchronized cylinders and valves.

2. Automatic axis referencing and calibrating when machine is turned on.

3. All ACCURL metal fabrication equipment are designed using SOLID WORKS 3D programming and made with enhanced ST44-1 quality steel with the latest technology.

4. Rigid upper beam runs on 8-point bearings with bending precision of 0.01 mm.

5. Well-known top and bottom tool brands are long lasting stiffened and provide precise bending.

6. Silent high pressure pump.

The best bending results You can bend longer and deeper parts with standard Speed-Bend Series.

Standard Equipment

1. Mono block, welded steel frame rigid to deflection and high tensile with ST44 A1 material.

2. 6 axes (Y1, Y2, X, R, Z1, Z2)

3. Back gauge system with X, R, Z1, Z2 axis driven by AC servo with colored graphics.

4. HOERBIGER servo hydraulic system.

5. CNC controlled motorized anti-deflection system.

6. Hardened and ground standard sectioned top and 4V-Die bottom tools (835 mm section).

7. Easy to clamp tool holding system with upper and lower tools.

8. Standard graphic controllers can be selected from: DelemDA66T 3D colour graphical touch screen controller, Cybelec Mod Eva 12 S

9. Electrical panel with cooling system designed to meet CE standards & composed of automation and electrical equipment with SIEMENS branding.

10. Ergonomic user friendly, pendant control panel.

11. Back light safety guards (category-4)

12. Front side covers with safety switches.

13. Synchronization of Y1 Y2 axis provided by linear encoders with 0,01 mm tolerances.

14. This metal forming machine uses foot pedal, is suitable to CE regulation.

15. Sliding front support arms with T slot and mm/inch rulers.

16. Throat depth 410 mm.

Delem DA66T CNC Control system

1. 2D graphical touch screen programming mode.

2. 3D visualisation in simulation and production.

3. 17" high resolution colour TFT.

4. Windows applications compatible.

5. Delem Modusys compatibility. (module scalability and adaptivity)

6. USB, peripheral interfacing.

7. Open system architecture.

8. User specific application support within the controllers multitasking environment.

9. Sensor bending & correction interface.

| Model(SC/MB8) | |||||||||

| Bending Capacity | kN | 630 | 630 | 1000 | 1000 | 1600 | 1600 | 2500 | |

| Max. Bending Length | mm | 1500 | 2500 | 3200 | 4200 | 3200 | 4200 | 3200 | |

| Between Columns | mm | 1100 | 2060 | 2700 | 3700 | 2700 | 3700 | 2700 | |

| Max. Shut Height | mm | 430 | 430 | 480 | 480 | 480 | 480 | 480 | |

| Slide Stroke | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Throat Depth | mm | 370 | 370 | 400 | 400 | 400 | 400 | 400 | |

| Bolster Width | mm | 150 | 150 | 200 | 200 | 200 | 200 | 200 | |

| Down Speed | mm/min | 100 | 100 | 130 | 130 | 130 | 130 | 110 | |

| Pressing Speed | mm/min | 8 | 8 | 10 | 10 | 10 | 10 | 10 | |

| Return Speed | mm/min | 100 | 100 | 125 | 125 | 125 | 125 | 110 | |

| Back Gauge Stroke | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Outline Size | L | mm | 1825 | 2825 | 3500 | 4500 | 3500 | 4500 | 3500 |

| W | mm | 1650 | 1650 | 1650 | 1650 | 1650 | 1650 | 1730 | |

| H | mm | 2600 | 2430 | 2540 | 2540 | 2580 | 2580 | 2580 | |

| Weight | kg | 4600 | 5600 | 8000 | 9500 | 10000 | 12000 | 15000 | |

| Model(SC/MB8) | |||||||||

| Bending Capacity | kN | 2500 | 3000 | 3000 | 3000 | 4000 | 4000 | 4000 | |

| Max. Bending Length | mm | 4200 | 3000 | 4000 | 6000 | 4000 | 5000 | 6000 | |

| Between Columns | mm | 3700 | 2500 | 3150 | 5050 | 3150 | 4050 | 5050 | |

| Max. Shut Height | mm | 480 | 480 | 480 | 480 | 480 | 480 | 480 | |

| Slide Stroke | mm | 200 | 200 | 200 | 200 | 320 | 320 | 320 | |

| Throat Depth | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Bolster Width | mm | 200 | 250 | 250 | 250 | 250 | 250 | 250 | |

| Down Speed | mm/min | 110 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Pressing Speed | mm/min | 10 | 8 | 8 | 8 | 8 | 8 | 8 | |

| Return Speed | mm/min | 110 | 85 | 85 | 85 | 80 | 80 | 80 | |

| Back Gauge Stroke | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Outline Size | L | mm | 4500 | 3300 | 4300 | 6400 | 4300 | 5300 | 6400 |

| W | mm | 1730 | 1950 | 1950 | 2000 | 2100 | 2100 | 2100 | |

| H | mm | 2580 | 2670 | 2670 | 2950 | 3100 | 3100 | 3170 | |

| Weight | kg | 17000 | 20000 | 22000 | 30000 | 27000 | 32000 | 38000 | |