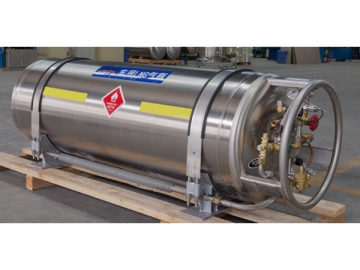

LNG Tank for Vehicle

LNG Tank Advantages

State of the art manufacturing equipment and technology ensures excellent performance

1. Automatic non-stop production line meets the requirements for manufacturing multiple kinds of liquefied natural gas tanks.

2. Top tier plate bending rolls realize full automatic control for feeding, bending and discharging, ensuring high precision and efficiency.

3. Superior welding equipment in fully automatic control can effectively ensure welding speed and quality.

4. Safe and clean ultrasonic cleaning technology lays a solid foundation for high quality LNG tanks.

5. World leading vacuum equipment and air leakage testing equipment, combined with nitrogen displacement and other process promise high vacuum degree for the pressure vessel.

6. Unique steel liner wrapping technology ensures high cryogenic property for the LNG storage tank.

- LNG Tank for Zhongtong Bus

- LNG Tank Used on SXQC Truck

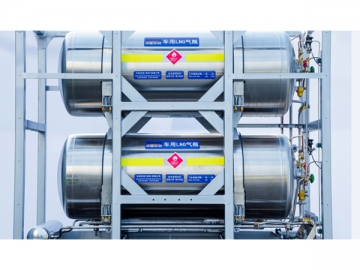

Light Weight Design for Liquefied Natural Gas Tank Assembly

Our LNG tank with double-layer air supply frame features 20kg/set weight reduction than similar gas storage equipment (taking 450L double-layer frame as an example).

An automobile manufacturer has completed a sampling test for weight of LNG cylinders from four different suppliers, including Sinoma. Results are shown as follows.

| LNG vessel manufacturer | Sinoma | T | F | S |

| Total weight ( KG ) | 782 | 807 | 805 | 803 |

3. Heat insulation performance of our LNG tank is far superior over manufacturing standard

| Low temperature performance index | Parameters comparison ( 450L as an example) | |

| Sinoma standard | Manufacturing standards | |

| Static evaporation rate | 1.67%/d | 2.1 %/d |

| Vacuum layer leakage rate | 2.3 ×10 -10 Pa ·m3/s | 6 . 0 ×10 -8 Pa ·m3/s |

| Leakage and degassing rate | 5.9 ×10 -10 Pa ·m3/s | 6.0 ×10 -7 Pa ·m3/s |

| Low temperature vacuum degree | 1.8 ×10 -3 Pa | 2 . 0 ×10 -2 Pa |

| Burning test time | 90min | 40min |

| Lossless storage time (test medium: liquid nitrogen) | More than 12 days | 5 days |

Sinoma LNG Tank Used on CNHTC Truck

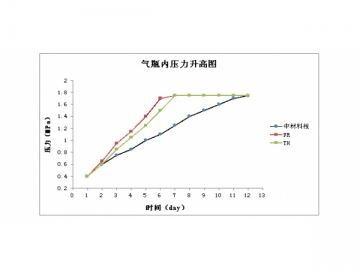

Sinoma LNG Tank Used on CNHTC Truck4. CNHTC did a comparison test for pressure and time of LNG tanks from three suppliers. Test results are shown below:

| Company / pressure / time | 17th | 18th | 19 th | 20 th | 21 th | 22 th | 23 th | 24 th | 25 th | 26 th | 27 th |

| Sinoma | 0.4 | 0.6 | 0.75 | 0.85 | 1.0 | 1.1 | 1.25 | 1.4 | 1.5 | 1.65 | 1.72 |

| A | 0.4 | 0.65 | 0.95 | 1.15 | 1.4 | 1.7 | 1.8 | 1.75 | 1.8 | 1.8 | 1.8 |

| B | 0.4 | 0.6 | 0.85 | 1.05 | 1.25 | 1.5 | 1.75 | 1.75 | 1.8 | 1.75 | 1.75 |

LNG cylinder internal pressure rising chart

LNG cylinder internal pressure rising chartResults shows

a. The natural gas tank from A supplier started the first gas releasing on March 23rd.

b. The natural gas tank from B supplier conducted the first gas releasing on March 23rd, and automatically closed the valve after loss of pressure.

c. Sinoma's tank released gas at 1 am on March 27th, and automatically closed the valve after loss of pressure.

Conclusions

a. The heat insulation performance and evaporation rate of Sinoma's LNG tank are superior over that of other suppliers.

b. Lossless storage time of Sinoma's LNG tank is 4 days longer that those of A and B suppliers.

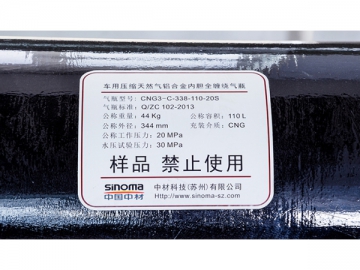

Technical Parameters

| Standard | Series | Model | Working pressure (MPa) | Nominal volume (L) | Effective volume (L) | Maximum filling capacity (kg) | Outer cylinder inner diameter (mm) | Cylinder length (mm) | Cylinder weight (kg) | Safety valve opening pressure (level 1 / 2) (MPa) | Static evaporation rate (%/d) |

| Q/ZC 110 | CDPW450 | 1.59 | 150 | ≈135 | ≈58 | 500 | 1342 | ≈120 | 1.72/2.41 | LN 2 : ≤2 .9 | |

| 1.59 | 170 | ≈153 | ≈66 | 500 | 1468 | ≈129 | 1.72/2.41 | LN 2 : ≤2 .66 | |||

| 1.59 | 200 | ≈180 | ≈77 | 500 | 1656 | ≈143 | 1.72/2.41 | LN 2 : ≤2 .3 | |||

| 1.59 | 210 | ≈189 | ≈81 | 500 | 1719 | ≈149 | 1.72/2.41 | LN 2 : ≤2 .29 | |||

| 1.59 | 245 | ≈221 | ≈95 | 500 | 1939 | ≈165 | 1.72/2.41 | LN 2 : ≤2 .26 | |||

| 1.59 | 275 | ≈248 | ≈106 | 500 | 2128 | ≈180 | 1.72/2.41 | LN 2 : ≤2 .23 | |||

| 1.59 | 294 | ≈265 | ≈114 | 500 | 2247 | ≈189 | 1.72/2.41 | LN 2 : ≤2 .21 | |||

| CDPW500-II | 1.59 | 150 | ≈135 | ≈58 | 550 | 1207 | ≈112 | 1.72/2.41 | LN 2 : ≤2. 9 | ||

| 1.59 | 170 | ≈153 | ≈66 | 550 | 1308 | ≈116 | 1.72/2.41 | LN 2 : ≤2. 9 | |||

| 1.59 | 175 | ≈158 | ≈68 | 550 | 1334 | ≈123 | 1.72/2.41 | LN 2 : ≤2. 4 | |||

| 1.59 | 180 | ≈162 | ≈70 | 550 | 1359 | ≈125 | 1.72/2.41 | LN 2 : ≤2. 4 | |||

| 1.59 | 200 | ≈180 | ≈77 | 550 | 1461 | ≈133 | 1.72/2.41 | LN 2 : ≤2. 3 | |||

| 1.59 | 210 | ≈189 | ≈81 | 550 | 1512 | ≈137 | 1.72/2.41 | LN 2 : ≤2. 3 | |||

| 1.59 | 215 | ≈194 | ≈83 | 550 | 1538 | ≈140 | 1.72/2.41 | LN 2 : ≤2. 3 | |||

| 1.59 | 240 | ≈216 | ≈93 | 550 | 1665 | ≈150 | 1.72/2.41 | LN 2 : ≤2. 3 | |||

| 1.59 | 245 | ≈221 | ≈95 | 550 | 1690 | ≈152 | 1.72/2.41 | LN 2 : ≤2. 3 | |||

| 1.59 | 275 | ≈248 | ≈106 | 550 | 1843 | ≈165 | 1.72/2.41 | LN 2 : ≤2. 3 | |||

| 1.59 | 280 | ≈252 | ≈108 | 550 | 1869 | ≈167 | 1.72/2.41 | LN 2 : ≤2. 3 | |||

| 1.59 | 294 | ≈265 | ≈114 | 550 | 1940 | ≈173 | 1.72/2.41 | LN 2 : ≤2. 3 | |||

| 1.59 | 310 | ≈279 | ≈120 | 550 | 2021 | ≈180 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 330 | ≈297 | ≈128 | 550 | 2123 | ≈188 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| CDPW600 | 1.59 | 335 | ≈302 | ≈130 | 660 | 1617 | ≈205 | 1.72/2.41 | LN 2 : ≤2.2 | ||

| 1.59 | 350 | ≈315 | ≈136 | 660 | 1670 | ≈211 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 375 | ≈338 | ≈145 | 660 | 1759 | ≈221 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 400 | ≈360 | ≈155 | 660 | 1847 | ≈231 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 450 | ≈405 | ≈174 | 660 | 2024 | ≈251 | 1.72/2.41 | LN 2 : ≤2.1 | |||

| CDPW600-II | 1.59 | 280 | ≈252 | ≈86 | 650 | 1394 | ≈177 | 1.72/2.41 | LN 2 : ≤2. 3 | ||

| 1.59 | 300 | ≈270 | ≈116 | 650 | 1464 | ≈185 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 310 | ≈279 | ≈120 | 650 | 1500 | ≈190 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 320 | ≈288 | ≈124 | 650 | 1535 | ≈194 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 335 | ≈302 | ≈130 | 650 | 1588 | ≈200 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 340 | ≈306 | ≈132 | 650 | 1606 | ≈202 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 350 | ≈315 | ≈136 | 650 | 1641 | ≈206 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 360 | ≈324 | ≈139 | 650 | 1677 | ≈210 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 375 | ≈338 | ≈145 | 650 | 1730 | ≈216 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 380 | ≈342 | ≈147 | 650 | 1747 | ≈218 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 400 | ≈360 | ≈155 | 650 | 1818 | ≈226 | 1.72/2.41 | LN 2 : ≤2.2 | |||

| 1.59 | 450 | ≈405 | ≈174 | 650 | 1995 | ≈246 | 1.72/2.41 | LN 2 : ≤2.1 | |||

| 1.59 | 500 | ≈450 | ≈194 | 650 | 2172 | ≈267 | 1.72/2.41 | LN 2 : ≤2. 0 | |||

| CDPW600-III | 1.59 | 450 | ≈405 | ≈174 | 660 | 2024 | ≈251 | 1.9/2.76 | LN 2 : ≤2.1 | ||

| 1.59 | 500 | ≈450 | ≈194 | 660 | 2201 | ≈271 | 1.9/2.76 | LN 2 : ≤2 .0 | |||

| CDPW650-II | 1.59 | 450 | ≈405 | ≈174 | 700 | 1775 | ≈236 | 1.72/2.41 | LN 2 : ≤2.1 | ||

| 1.59 | 500 | ≈450 | ≈194 | 700 | 1925 | ≈255 | 1.72/2.41 | LN 2 : ≤2. 0 |