Full Ceramic Bearing

Full ceramic bearings are made completely from ceramic material. Ceramic is an excellent material for applications that require higher speeds, reducing overall weight, or extremely harsh environments where high temperatures and corrosive materials are present. Full ceramic bearings feature a high temperature resistance, cold resistance, and corrosion resistance. They also feature magnetoelectricity insulation, oil-free self-lubrication and a high rotary speed.

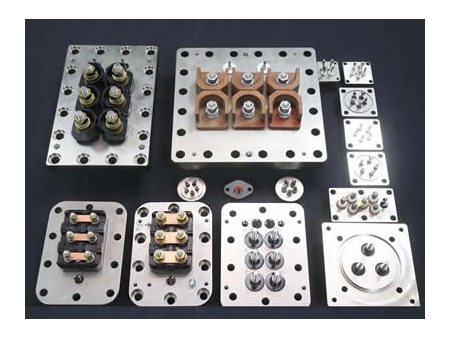

Available Types

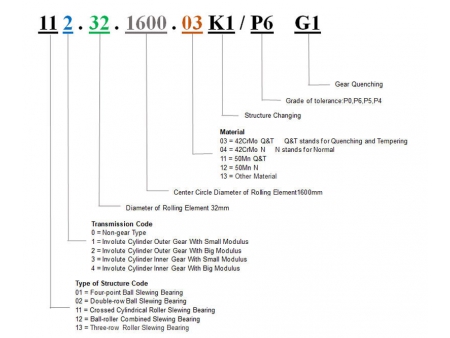

Each of our full ceramic bearings are made from quality ceramic and come in a number of types, including Zirconia ceramic bearings (ZrO2), silicon nitride ceramic bearings (Si3N4), silicon carbide bearings, and alumina ceramic bearings (AI203). Each of these is suitable for harsh environments and special working conditions. They are widely used in aviation, oil, automobile, electronic equipment, metallurgy industries and more. The cages are available in PTFE, PEEEK, PA66, PI, Zirconia, stainless steel, or aerospace aluminum, each of which can assist in expanding applications of the ceramic bearings.

Features of Full Ceramic Bearings

1. High Speed: Extremely resistant to cold and pressure, and featuring a low elasticity, small heat conductivity, light weight and a low friction coefficient, the ceramic bearing is applicable for spindles that rotate at 12,000r/minute to 75,000r/min and other high precision equipment. (This high speed bearing refers to the mixed ceramic ball bearings).

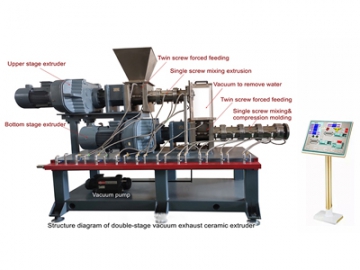

2. High Temperature Resistance: With a heat resistance up to 1,200℃ and featuring excellent self-lubricating performances, this bearing will not undergo expansions caused by temperature differences when working at temperatures ranging from 100-800℃. This makes it suitable for high-temperature equipment such as furnaces, kilns, plastic machinery and steel making machinery.

3. Corrosion Resistance: Made from anti-corrosion materials, this bearing is applicable to acid, alkali, inorganic and organic salts, sea water and more. It is mainly used for plating equipment, electronic equipment, chemical machinery, ship building, and medical equipment.

4. Anti-Magnetic: As magnetism draws dust that becomes insulated, this bearing has less spallings ahead of maintenance times, and a lower operation noise. It is applicable to demagnetization equipment, precision equipment and more.

5. Electric-Insulated: The high resistance of this bearing helps protect it from damage caused by electric arcs. It is suitable for power equipment that has high requirements for electric insulation.

6. Vacuum Conditions: As ceramic materials have self-lubricating properties, this ceramic bearing can work well in ultra-high vacuum conditions without any lubricants that are commonly used in most bearings.

Selections

We provide customers with quality bearings, including those mentioned above. All bearings in a set can be used for high temperatures, high speeds, acids, alkalis, magnetic fields, and non-insulated conditions. However, the performances of any given bearing can differ from others based on the different materials. Inform us of the application for your bearing during the selection process, and we will assist you in finding the best suited ceramic bearing for your project needs.