Lost Foam Casting

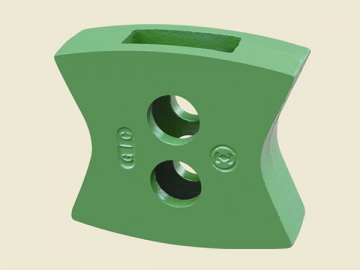

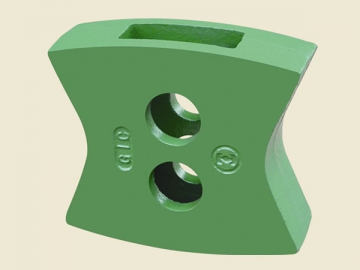

Name: Blow bar

Casting process: Lost foam casting (LPC)

Material standards: ASTM, JIS, AISI, DIN, GB

Weight range: 1kg ~30kg

Annual output: 700T

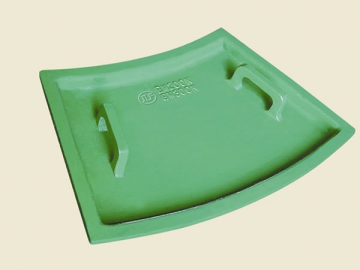

Name: Grate bar

Casting process: Lost foam casting (LPC)

Material standards: ASTM, JIS, AISI, DIN, GB

Weight range: 1kg ~30kg

Annual output: 700T

What is Lost Foam Casting Process?

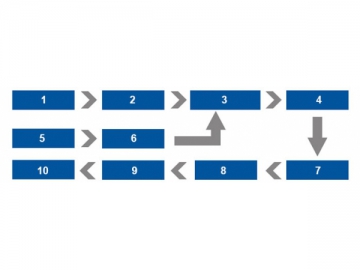

Lost foam casting process, also known as full mold casting process is a new type casting method. In this casting process, the foam pattern that has same dimension with the casting will be first coated with refractory material and placed into quartz sand or forsterite sand after coating is dried. Then the sand will be compacted using a vibration table. Once compacted, the mold is ready to be poured at negative pressure. The melted metal will be directly poured into the foam-filled mold, burning out the foam and take up the place where it stays. Finally, the melt forms the casting after it is cooled and solidified.

| 1. Original Polystyrene Beads 2. Foaming and Pattern Molding 3. Foam Cluster Assembly 4. Coating Refractory Material and Drying 5. Foam board | 6. Pattern Molding 7. Sand Filling and Vibration Compacting 8. Vacuum Pouring 9. Cooling 10. Casting |

Why Choosing Mayang?

1. Professional

Since its foundation in 1985, Mayang has been committed to the manufacture of castings. We can enforce production in various international standards such as ASTM, JIS, AISI, DIN and GB, thus meeting the requirements of customer in different market. Now, we can produce 700 tons castings per year using lost foam casting process. In addition, we have obtained a number of international certification including ISO9001:2008, ISO14001:2004 and OHSAS18001:2007.

2. Quality Control

Mayang attaches great importance to quality control. It has equipped multiple test equipment such as 4 sets of physical and chemical test equipment, OBLF direct-reading spectrometer made in Germany, OXFORD direct-reading spectrometer, high frequency IR carbon and sulfur analyzer, metallographic microscope, mechanical property test equipment, hardness test equipment, etc.

3. Case and Performance

So far, Mayang has successfully served hundreds of customers with quality metal castings. Among which, there are several leading enterprises in various industries around the world. Our export performance in 2012 exceeded 20 million US dollars.