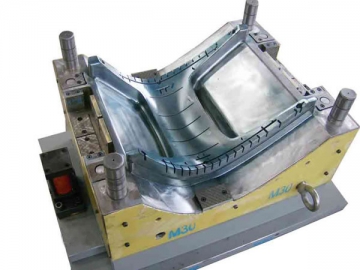

Compression Mold

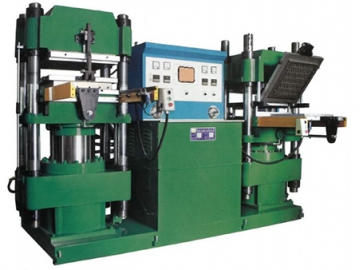

As a compression mold expert in China, Haiyee has invested years of research and development in improving mold quality and tooling solutions. With advanced equipment, we produce superior compression molds. There is no better way of testing a mold than on our own machine at our own facility. That is why we bought the 1500t hydraulic press, or compression molding press, for mold trials. The advanced mold heater is installed on the press to apply heat during the molding process.

Compression molding is often chosen for medium-hardness compounds, such as SMC and BMC.

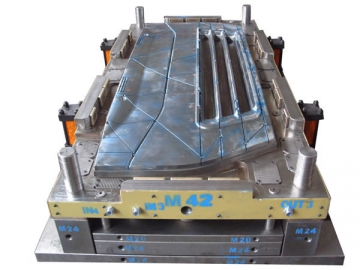

Composites like SMC have long been used in autos and trucks, though the most rigid vehicle panels are often made of steel using stamping dies. Here we list some auto body parts that can be produced by Haiyee's auto molds.

Exterior Car Trims: bumper covers, mud flaps, wheel wells, spoilers, fenders, liftgates

Interior Car Trims: instrument panels, car door panels, sub-dash panels, glove boxes, and car seats, and various other protective panels

Functional and Structural Parts: petrol tanks, coolant reservoirs, air filter covers, fan blades, air intake hoses, and cylinder heads

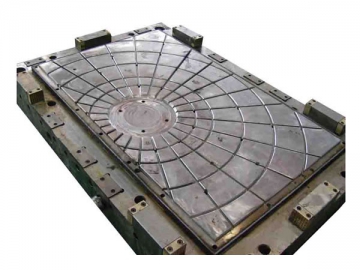

Besides auto parts, compression molding also produces bathroom shower fixtures, water tank accessories, motorcycle accessories, fitness equipment parts, and electric meter casings.

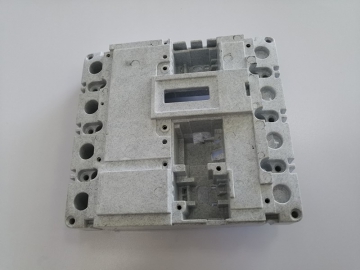

Applications for BMC compression molding extend across industries, for electrical and chemical engineering equipment as well as in the motor, radio station, instrumental, machinery manufacturing, construction, transportation and national defense industries.

To date, Haiyee has worked with many industry-leading companies, helping them develop and construct compression molds that make commercial car trims, home appliance parts, and shower parts. Our valued partners include Audi and Volkswagen in the automobile industry, Haier in the home appliance industry, Sany in the construction industry, and CSR Sifang Co. Ltd., in railway transportation.

Benefits of SMC, BMC compression molding

1. Compression molding is a cost-effective process for medium precision. The process is suitable for molding fiberglass reinforcements and producing very large components with tensile strength of more than 250lbs.

2. Fiberglass-based composites like SMC and BMC can be left in the mold cavity while achieving optimal fiber orientation. The result is high stiffness and strength in a single fiber direction. The process is not limited to where the mold gate is located.

3. Various materials can be added to the cavity for improved component strength, including fiber glass mats and uni-directional glass.

4. A very economical process for low-volume (less than 1,000 units) production. Large-volume production is also possible with multi-cavity compression molds.

What can Haiyee do for you?

With years of experience in serving the fiberglass-based compression molding industry, we are capable of designing, developing, and building compression molds for your low and high-volume production. We provide technical support for new start-up companies in the mold tooling business, and recommend some of the best suppliers for hydraulic presses, SMC fiberglass, and BMC fiberglass.

At Haiyee, our mission is to keep your compression molding operation up and running. Even if you don't have in-house molding capability, we can develop and run compression molds to produce your desired fiberglass components.

Haiyee Compression Mold Basics

Steel grade: P20, NAK80, 718, SKD11, 618, S136, 45#, 50#, S50C

Components: mold cavity, guide pins, ejector pins, mold heating system

Heating method: oil, steam, electricity

Applications for Compression Mold