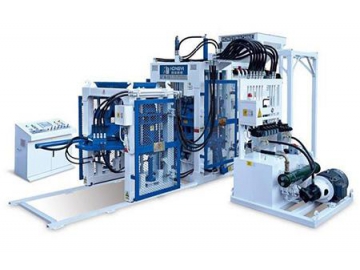

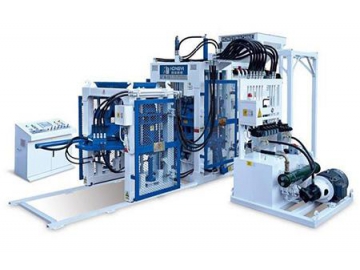

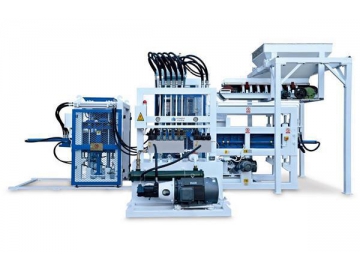

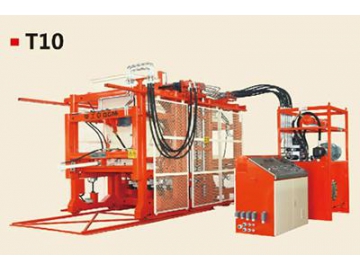

Concrete Block Making Machine, QT9-15

Technical Parameters of QT9-15 Concrete Block Making Machine

| Vibration frequency | 3800-4500times/sub | ||||

| Total weight | 14200kg | ||||

| Overall dimension | 9800×4050×2800mm | ||||

| Installed capacity | 45.2kW | ||||

| Cycle time | 15-20s | ||||

| Rated pressure | 31.5Mpa | ||||

| Exciting force | 105kN | ||||

| Plate specification | 1350×680×30mm | ||||

| Molding way | Vibration extrusion forming | ||||

| Stacker capacity | 3kW | ||||

| Block | Hollow block | Solid brick | Porous brick | Pavement brick | |

| Picture |  |  |  |  |  |

| Size | 390×190×190 | 240×115×51 | 240×115×90 | 200×100×60/80 | 250×250×60 |

| Molding blocks | 9pcs/mold | 50pcs/mold | 25pcs/mold | 33pcs/mold | 9pcs/mold |

| Molding cycle | 15~20s | 20~30s | |||

| Per hour production | 1620pcs/1h | 9000pcs/1h | 4500pcs/1h | 5940pcs/1h | 1620pcs/1h |

| Class production | 12500- 17000pcs/8h | 85000- 95000pcs/8h | 36000- 45000pcs/8h | 45000- 60000pcs/8h | 12500- 17000pcs/8h |

| Excitation frequency | 50~60Hz | ||||

| Block height | 50~200mm | ||||

| Power of main motor | 45.2kW | ||||

| Machine size | 9800×4050×2800mm | ||||

| Machine weight | 14200kg | ||||

**Note: The above parameters are for reference only. Modifications and upgrades are available. Contact us directly for more information.

Characteristics

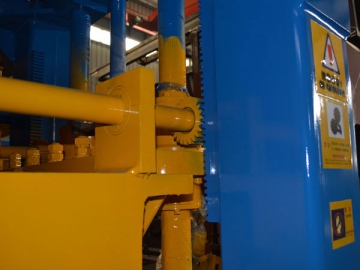

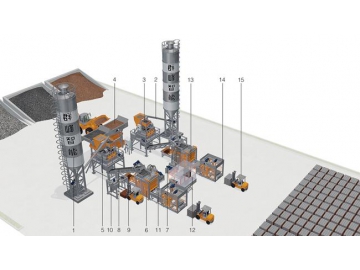

1. Excellent mechanical, electrical and hydraulic performances all give the QT9-15 concrete block making machine a reliable and high concrete product output.

2. The cycle time of the automatic block forming machine is improved due to the applications of productive molding devices including a 360º rotating and compulsory raw material feeding device, the vibrating table and the compression device.

3. As the molds can be changed, the concrete block making machine is a multi-functional block machinery used to produce different blocks, bricks, interlocks, pavers and curbstones in different shapes and sizes.

4. Equipped with a face mix device, it is possible for the hydraulic block making equipment to produce pavers with colored layers.

Maintenance

In order to keep the concrete block making machine operating smoothly and longer, proper care needs to be taken with the machine.

1. Make sure the concrete block machine does not vibrate if there is no material in it. Reduce unnecessary trail vibrations of the concrete block production machine.

2. Minimize equipment movement frequency in order to slow down the failure rate of the inner parts.

3. Ensure both the upper and lower molds clamp to each other in the correct position. Otherwise, the molds or other parts of the concrete block making machine may end up being damaged.

4. Regularly check the distance between the approach switches and the induction magnet to prevent equipment accidents that result from switch failure.

Pictures of Details

- Molds

- Molds

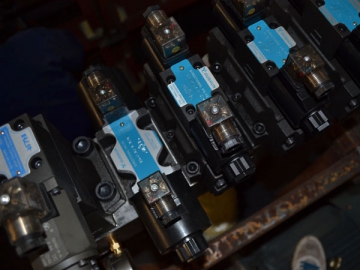

- Hydraulic components

- Bearings

For more molds and samples, please click ""