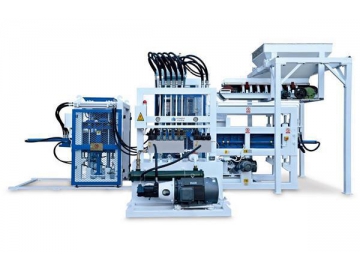

Concrete Block Making Machine, QT5-15

Technical Parameters of QT5-15 Concrete Block Making Machine

| Vibration frequency | 3800-4500times/sub | ||||

| Total weight | 6900kg | ||||

| Overall dimension | 9450×3300×2700mm | ||||

| Installed capacity | 31.4kW | ||||

| Cycle time | 15-20s | ||||

| Rated pressure | 25Mpa | ||||

| Exciting force | 68kN | ||||

| Plate specification | 1100×560×20mm | ||||

| Molding way | Vibration extrusion forming | ||||

| Stacker capacity | 3kW | ||||

| Block | Hollow block | Solid brick | Porous brick | Pavement brick | |

| Picture |  |  |  |  |  |

| Size | 390×190×190 | 240×115×51 | 240×115×90 | 200×100×60/80 | 250×250×60 |

| Molding blocks | 5pcs/mold | 34pcs/mold | 16pcs/mold | 18pcs/mold | 8pcs/mold |

| Molding cycle | 15~20s | 20~30s | |||

| Per hour production | 900pcs/1h | 6120pcs/1h | 2880pcs/1h | 3240pcs/1h | 1440pcs/1h |

| Class production | 7200- 11520pcs/8h | 49000- 61440pcs/8h | 23000- 28800pcs/8h | 23900- 30000pcs/8h | 10500- 13000pcs/8h |

| Excitation frequency | 50~60Hz | ||||

| Block height | 50~200mm | ||||

| Power of main motor | 31.4kW | ||||

| Machine size | 9450×3300×2700mm | ||||

| Machine weight | 6900kg | ||||

**Note: The above parameters are for reference only. Modifications or upgrades are available. Contact us directly for details.

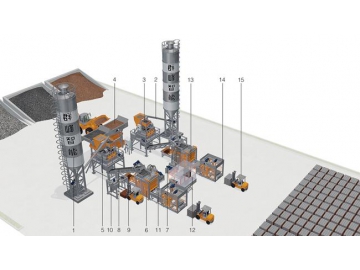

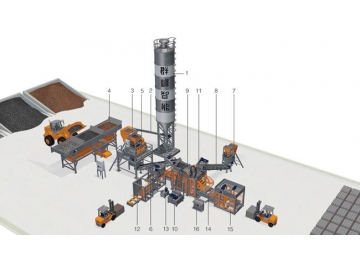

The QT5-15 concrete block making machine is capable of making 5 blocks in each mold at 300 x 200 x 100mm, and the molding cycle lasts 20 seconds. The daily production output of this brick forming machine, during an 8 hour day, is 8,000 blocks. By changing the molds, the automatic block machine can make different types of blocks, bricks and other concrete products.

We have specialized in developing and supplying concrete block making machines for over 10 years. With more than 50 technicians and engineers assigned to different parts of the world, we can offer on-site installation guidance and operator training.

Due to the extended working period of the concrete block making machine, its rubber parts, brushes, bolts, springs, bearings, and other components will be exposed to wear and tear. Because of this, proper operation and maintenance is required. In order to ensure the multi-functional block making machine works correctly, we supply spare parts for replacement along with the machine. Customers can also get these spare parts from local markets. Our concrete block making machine comes with a one-year warranty. For any additional needs or problems, please feel free to contact us, and we will work to meet your needs or solve your problems as soon as possible.

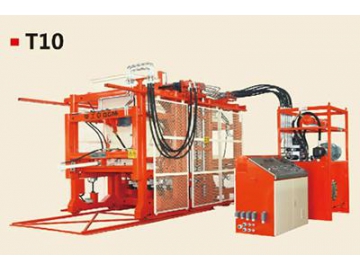

Pictures of Details

- Detail of the main machine

- Vibrating table

- Hydraulic stick

- Bearing

For more molds and samples, please click ""