Cooling Machine

- Counter flow cooler

- Stainless steel cooler

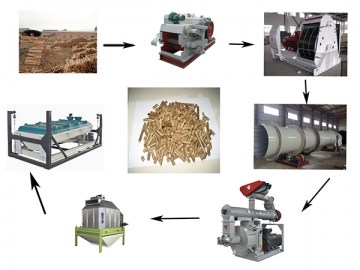

Application

As feed pellets are discharged from the pellet mill, their temperature can reach 70 to 90ºC. Cooling is an essential process for feed pellet production. The SKLN series of counter flow coolers are able to cool the pellets that are discharged from the pellet mill to a temperature that is only 3 to 5ºC higher than room temperature. At the same time, the water content in the pellets will be reduced by more than 3% during the cooling process. By doing so, the quality of the finished pellet is guaranteed during the packaging, transportation and storage processes. This makes the counter flow cooler an important piece of equipment in feed pellet plants.

Our counter flow coolers are not only suitable for cooling pellets in any shape, but they also come in a variety of models with different production capacities, making them adaptable to different sized feed processing factories.

Features

1. This pellet cooler has a larger cooling volume and a longer cooling cycle, which increases the cooling effects.

2. An airlock is used for material feeding, preventing air flow into the material feed inlet. This design also allows for better cooling effects.

3. Our counter flow cooler is equipped with an adjustable tapered material distribution device that distributes the material in a uniform manner.

4. The top of the feed pellet cooling equipment is made of stainless steel, making it highly corrosion resistant and durable.

5. The slide valve reciprocating discharge mechanism discharges materials in a reliable and stable manner.

| Model | |||||||

| Cooling volume (m3) | 1.5 | 2.5 | 4 | 6 | 8 | 10 | 12 |

| Production capacity (t/h) | 3 | 5 | 10 | 15 | 20 | 25 | 30 |

| Cooling time (min) | Not less than 6~10min | ||||||

| Material temperature after cooling | 3~5°C higher than the room temperature at most | ||||||

| Air volume (m3 /min) | 34 | ||||||

| Working power (kW) | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Feeder power (kW) | 0.75 | 0.75 | 0.75 | 0.75 | 1.1 | 1.1 | 1.1 |

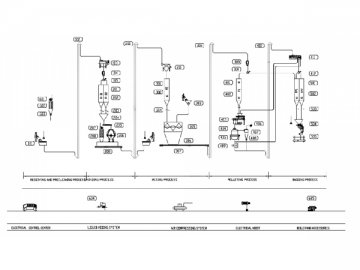

Working Principle and Performance Advantages

Our counter flow cooler is a new pellet cooler that cools high temperature and high humidity pellets using counter flow cooling, which works as follows. Cool air goes through the pellet material layer in a vertical manner, in a direction opposite to the material flowing direction. By doing so, cool air first contacts cooler pellet materials, and gradually, heated air contacts high temperature materials and cools them slowly. This method avoids direct contact of the cool air and high temperature pellet materials, preventing pellet cracking that results from shock cooling.

As the cool air enters the counter flow cooler from the bottom, the air intake area is enlarged and the cool air utilization ratio is increased, providing better cooling effects. This stainless steel cooler not only has a low consumption, but it is highly automated and easy to operate. It is a new cooling machine that works more efficiently than a traditional vertical or horizontal cooler.

Related Names

Cooler | Counterflow Cooler | Feed Pellet Cooler | Feed Pellet Plant