Roll Forming Line

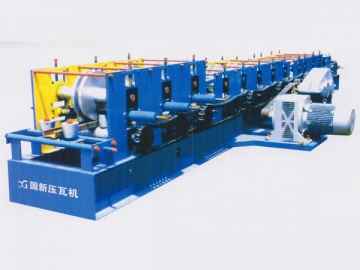

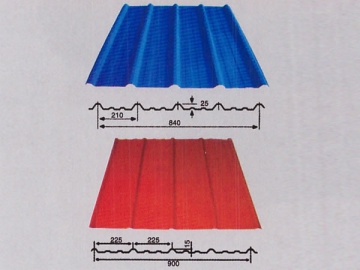

Guoxin roll forming lines consist of a main roll forming machine, or roll former, a PLC control system, hydraulic power pack, and an automatic shearing system. They will carry out various sheet metal processes from feeding to roll forming through to cutting. The profiles made by our roll forming system come with a uniform coating, high strength and durability, and are widely used for roof and wall panels of industrial and civil buildings such as workshops and warehouses.

Advantages

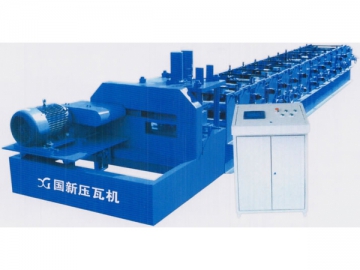

Our roll forming lines employ high level automatic control software, realizing production information management. Depending on a highly integrated network, the automatic control system for the whole panel roll forming line boasts superior performance. Additionally, the roll forming machinery features ease of operation, maintenance, commissioning, die changing, etc.

Functions

1. The roll forming line employs the KDN-K306-24AR PLC to achieve excellent high speed input performance, selects AB phase pulse to obtain strong resistance to interference, and uses an interrupt function at constant value to ensure precision.

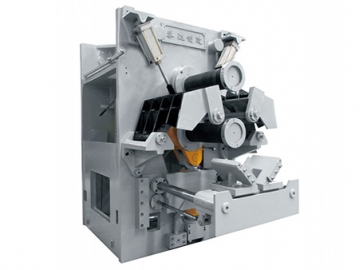

2. The system's detection parts include a pulse encoder for detection of color steel tile length, roll former vertical stroke switch, cutter vertical stroke switch, roll former vertical stroke button, cutter vertical stroke button, emergency stop switch, and a hydraulic start and stop switch.

3. Driving parts include a variable frequency motor, hydraulic power unit motor, two hydraulic solenoid valves for roll forming, and two hydraulic solenoid valves for cutting.

4. Depending on its control system, the roll forming machine can also realize single sheet metal cutting.