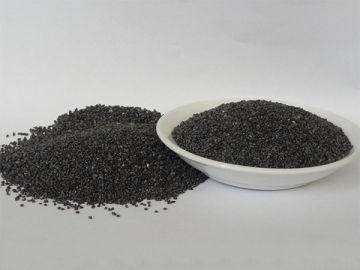

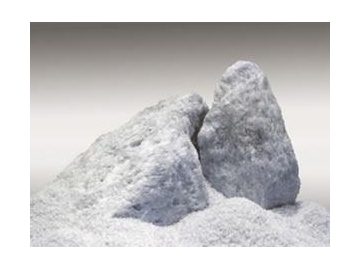

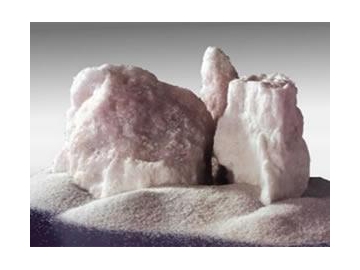

White Fused Alumina

Processing and Features

We also supply premium white fused alumina. It is made of industrial alumina powders that are smelted together in a high-temperature electric arc furnace at temperatures above 2,000ºC, and then subject to cooling, crushing, magnetic separation to remove iron, sieving and finally, classification. With our strict processes, the white corundrum has a high purity, shapes itself, acid and alkali resistance, thermal stability, low toughness and a higher hardness than brown corundrum. According to international standards, it is more commonly known as WA.

Applications of White Fused Alumina

Fused white aluminum oxide is a choice material for shaped and unshaped refractory materials. It can be used for ladle castables, iron castable gunning refractory, refractory gunning mix, pre-fabricated products such as unshaped refractory, corundrum bricks, corundrum or mullite corundrum saggers, corundrum porous plug bricks for refining, spray guns, composite nozzles, refractory lining such as furnace lining, and more. It is also widely used in steel, ceramic, cement, abrasive material and petrochemical industries.

Density

This alumina based product is available in different densities, including 1.53-1.99/cm³ (bulk density), and 3.95-4.0g/cm³ (true density).

Bulk Density is determined by size, type, grain shape and other factors. In general terms, the smaller the grain size, the large the bulk density.WFA with different grain sizes has a larger bulk density than that of uniform grain sizes.

True Density or particle density is the density of the particles that make up the powder, primarily the volume unit (except open pore volume) of the fused alumina.

Specification of White Fused Aluminum

As Refractory material: 12-6mm,10-8mm,8-5mm,5-3mm,3-1mm,1-0mm,1-0.5mm,0.5-0.212mm,0.5-0mm,0.3-0mm

As Abrasive Material: F8, F10, F12, F14, F16, F20, F22, F24, F30, F36, F40, F46, F54,F60, F70, F80, F90, F100, F120, F150, F180, F220

Physical Properties

B.D: >3.55g/cm3

Specific Gravity : 3.95g/cm3 Mohs

Hardness: 9.0

Melting Point: 2250 ºC

| Usage | Specifics | Main Chemical Composition % | ||||

| Al 2 O 3 | Na 2 O | Fe 2 O 3 | SiO 2 | Magnetic Substance | ||

| Abrasives | F12#--80# | ≥99.4 | ≤0.4 | ≤0.1 | ≤0.03 | - |

| 90#--150# | ≥99.3 | ≤0.4 | ≤0.1 | ≤0.05 | ≤0.03 | |

| 180#--240# | ≥99.2 | ≤0.4 | ≤0.1 | ≤0.03 | - | |

| 1#--63# | ≥99.3 | ≤0.4 | ≤0.1 | ≤0.05 | ≤0.03 | |

| Refractory | 180#--0 | ≥99.3 | ≤0.4 | ≤0.1 | ≤0.05 | ≤0.06 |

| 200#--0 | ||||||

| 320#--0 | ||||||

| Fine Powder | 0-1mm | ≥99 | ≤0.4 | ≤0.1 | ≤0.02 | ≤0.1 |

| 1-3mm | ||||||

| 3-5mm | ||||||

| 5-8mm | ||||||

| 8-12mm | ||||||