Ceramic Proppant

Application

Ceramic proppant’s most distinct feature is its ability to increase oil and gas production in wells and extend the well service life, especially in deep wells. It has been proven that quality ceramic proppants can effectively promote the oil and gas production of a well by 30 to 50%, and thus it is often used in oilfield industry to serve as hydraulic fracturing proppants.

This ceramic proppant has a high density, as well as excellent chemical and thermal stability. It is an excellent substitute for building materials such as river and silica sand and can be used in lightweight concrete, lightweight mortar, and fine aggregate concrete that is anti-acid and anti-heat. It can also be used as growing media in soilless cultivation and industrial filter media.

Our Advantages

Ceramic proppants are frac sand made from ceramic with high quality bauxite iron and other raw materials. It primarily serves as a substitute for other low-strength proppant, such as natural quartz sand and glass balls. Chennuo is located in Yichuan, Luoyang City, where large reserves of coal and bauxite have been located. Because of that, we have reliable raw material availability, ensuring our productivity and premium quality products. High strength proppants are also available at cost effective prices.

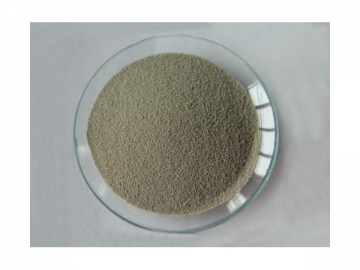

Specification of Ceramic Proppant

| Specification | Bulk density | Particle | Roundness | Solubility | Turbidity | Crush | Pressure |

| 425 ~212 (40/70) | ≤1.65 | ≤3.00 | ≥0.8 | ≤7.5 | ≤100 | ≤10 | 86 |

| Specification | Bulk density | Particle | Roundness | Solubility | Turbidity | Crush | Pressure |

| 850~425 (20/40)ISP | ≤ 1.80 | ≤3.35 | ≥0.9 | ≤7.5 | ≤100 | ≤4 | 52 |

| ≤7 | 69 |

| Specification | Bulk density | Particle | Roundness | Solubility | Turbidity | Crush | Pressure |

| 425~212 (40/70) | ≥1.80 | ≥3.35 | ≥9 | ≤7.5 | ≤100 | ≤5 | 69 |

| ≤7 | 86 |

Features of Ceramic Proppant

Hydraulic fracturing proppant features a low density, high oil fracturing performance, excellent thermal insulation, impermeability resistance, alkalinity resistance, low water absorption, and excellent frost resistance.

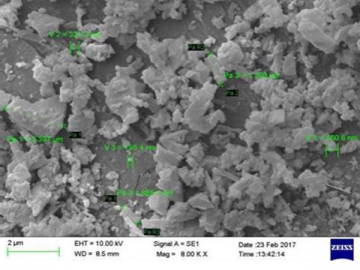

Manufacturing Technique

Bauxite and manganese powder, coal, and other materials will be blended before drying and crushing. The crushed mixture will be turned into grains using a pan pelletizer, which will be calcinaed, cooled, and sieved according to grain sizes.