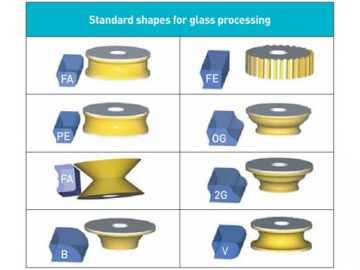

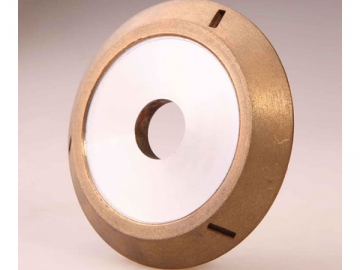

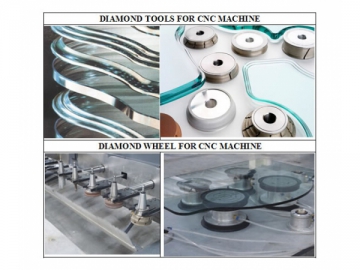

Peripheral Wheels (CNC)

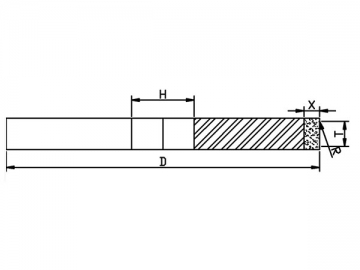

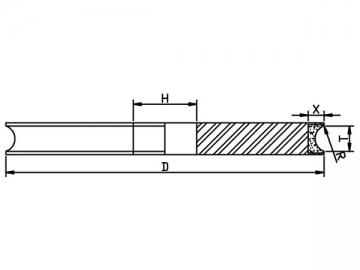

Trapezoid wheel

Trapezoid wheel Flat edging wheel

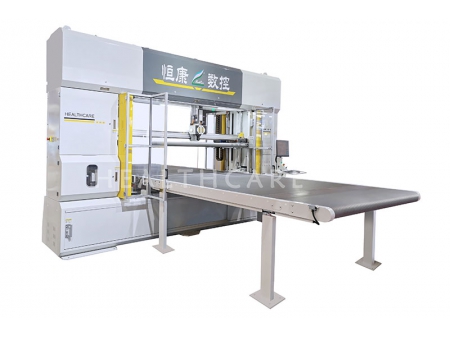

Flat edging wheelThe peripheral wheel is most often installed on the beveling machine, double edger, CNC grinding machine, and straight edger. This range of metal bonded diamond blades works well on glass, quartz, stone and chinaware.

| Pencil / Trapezoid / Flat edging wheel | |||

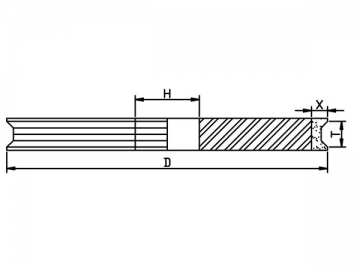

| Diameter (mm) | Thickness (mm) | Hole | Grit Size |

| 100,150,175,200 | 3 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# |

| 4 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

| 5 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

| 6 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

| 8 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

| 10 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

| 12 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

| 15 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

| 19 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

| 20 | 12/22/32 | 100#/120#/150#/170#/200#/240#/320#/400# | |

- Pencil wheel

- Trapezoid wheel

- Flat edging wheel

| OG 2OG 30G diamond wheel | |||

| Diameter (mm) | Thickness (mm) | Diameter (mm) | Thickness (mm) |

| 100 | 3 | 150 | 3 |

| 100 | 4 | 150 | 4 |

| 100 | 5 | 150 | 5 |

| 100 | 6 | 150 | 6 |

| 100 | 8 | 150 | 8 |

| 100 | 10 | 150 | 10 |

| 100 | 12 | 150 | 12 |

| 100 | 15 | 150 | 15 |

| 100 | 19 | 150 | 19 |

| 100 | 20 | 150 | 20 |

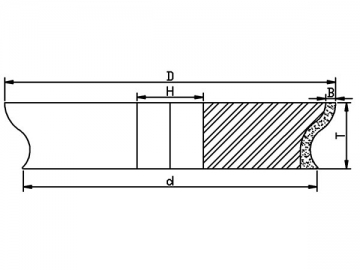

| Diameter | 100mm |

| Thickness | 10mm -30mm |

| Grit | 80#-320# |

| Custom specifications | |

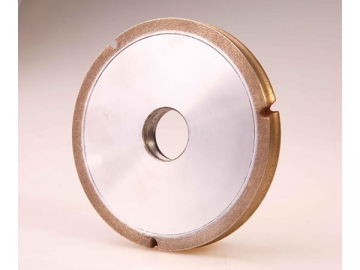

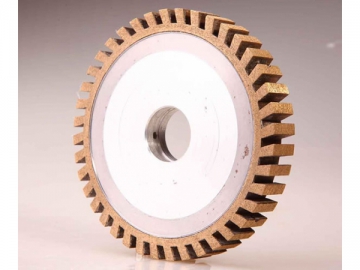

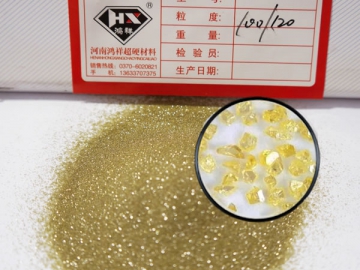

These sintered centerless grinding wheels consist of a steel core and diamond segments that are made by sintering high grade diamond crystals and metal powder at high temperatures and pressure.

When installed on an angle grinder, the diamond blade can grind glass a high, steady speed. The blade will not cause chipping, rupturing or burns, even when working without water for cooling. It grinds in a flexible manner and lasts longer than competitive blades. When harder materials need to be ground, we suggest using a finer diamond grit.

Applications

The peripheral wheel is suitable for cutting and grinding flat glass, frosted glass, sandblasted glass, embossed glass, wired glass, insulated glazing, laminated glass and glass brick. The grit size is between 80 and 150 mesh size, and is unlikely to cause a rupture in the glass.

For cutting granite, basalt, limestone, dolomite, malmstone, and marble, we suggest picking grit sizes between 36 and 60.Diamond blades that range in size can handle these stones at high speeds without causing cracks or ruptures.

When most of the cutting and grinding work to be done involves ceramic, silicate products and silicon wafers, customers may want to choose a sintered diamond blade with a grit size between 80 and 120.

Metals such as aluminum and stainless steel can also be ground using the peripheral wheels.

| Cup wheel for angle machine | |

| Diameter | 100mm |

| Grit | 80#-320# |

| Can be custom-made | |

- Peripheral Segmented V-wheel

- Peripheral V-wheel

- CNC FA wheel

- Straight edge wheel

.jpg)