Paper Machine (for Printing and Writing Paper Making)

Structural Features of the Paper Machine

1. Headbox

This paper making machine is designed with an open headbox, which is composed of the taper pipe, stepped diffuser, rectifier roll and box. The pulp distributor with a pore plate made of organic glass comes with three step diffusion. The top and lower lips of the slice are made with stainless steel. The top lip has full and local control.

2. Forming Section (Wet End)

The fourdrinier table has a length of 18,000mm. With the exception of the bearing block, which is made of aluminum alloy, the rack is completely constructed from structural steels by welding, and covered by a layer of stainless steel at a 1.5mm width. The forming section of the paper machine consists of the breast roller, forming board, foils, suction boxes, vacuum couch roller, electric wire tightener, pneumatic corrector, and edgy warping device.

3. Press Section

In the press section, the fourdrinier machine uses a vacuum suction pickup roller and three suction rolls.

4. Dryer Section

This paper machine is equipped with 28 sets of φ1500mm steam-heated cylinders and one φ3000mm cylinder in the dryer section. Paper dryers are typically arranged in groups. The arrangement pattern is, in sequence: 6 dry cylinders, 6 dry cylinders, 8 dry cylinders, 1 dry cylinder, glue applicator and 8 dry cylinders. They are driven by a sealed gearbox and lubricated with a thin oil.

5. Drive and Control Section

This paper machinery uses a sectional drive system composed of an AC variable frequency motor, reduction gearbox with a hard teeth surface, and universal spindle coupling. It comes with an all-digital closed loop control system.

6. Calender Press Polish and Rewinding

Huaxia's printing and writing paper machine applies a super calender and horizontal paper winding machine.

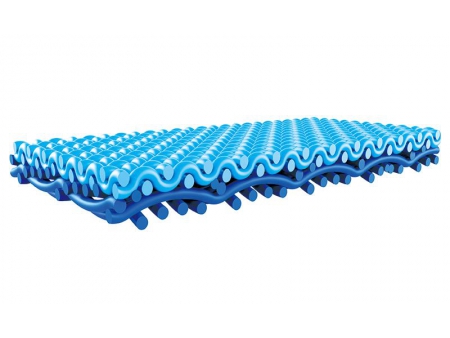

2.5-layer Forming Fabric for Printing & Writing Paper Making (5-shed/8-shed/10-shed)

forming-dryerfabrics.com

2.5-layer Forming Fabric for Printing & Writing Paper Making (5-shed/8-shed/10-shed)

forming-dryerfabrics.com

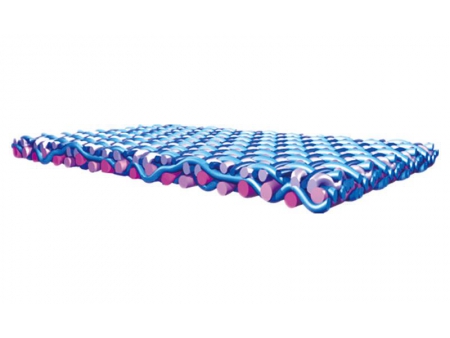

SSB Triple-layer Forming Fabric for Printing & Writing Paper Making (5-shed/8-shed/10-shed)

forming-dryerfabrics.com

SSB Triple-layer Forming Fabric for Printing & Writing Paper Making (5-shed/8-shed/10-shed)

forming-dryerfabrics.com

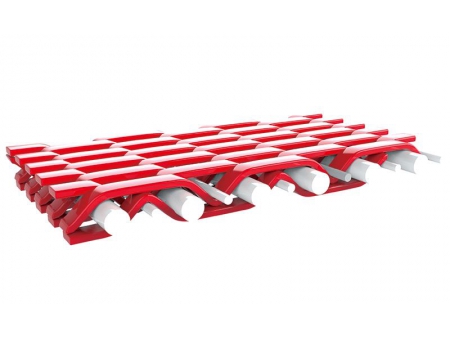

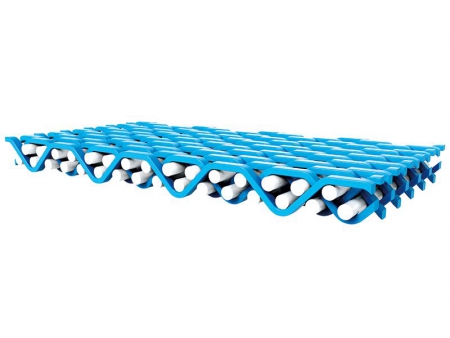

Single Warp Dryer Fabric for Printing & Writing Paper Production (Flat Yarn)

forming-dryerfabrics.com

Single Warp Dryer Fabric for Printing & Writing Paper Production (Flat Yarn)

forming-dryerfabrics.com