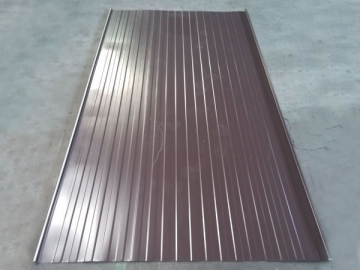

Roll Forming Machine (For Steel Facing Panels)

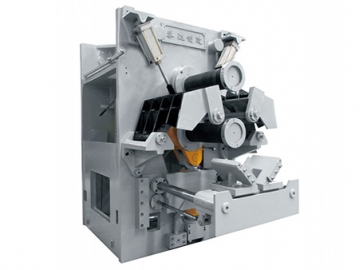

Fabricated for steel facing panel production, the roll forming machine is available with 13 groups of forming rollers supporting width adjustment. One side of the roller is fixed, while the other side can be adjusted via screw. Therefore, the metal forming equipment can be used to make steel profiles with varied width.

In the middle section of the roll forming machine, there are pressing wheels which support upper and lower movement. They are used to clamp and fix feeding materials, thus making sure the material will not curve during forming process.

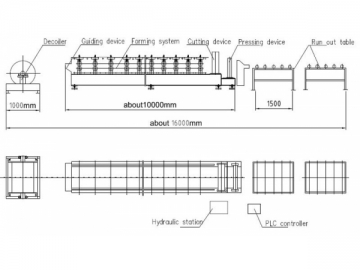

Technical Data of the Roll Forming Machine| Suitable material | Q235 color steel sheet; 0.3-0.7mm, |

| Forming speed | about 20m/min |

| Power Requirement | Main motor power: 5.5 Kw (Depend on final design) |

| Hydraulic station power | 2.2Kw (Depend on final design) |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 7000KGS |

| Machine's size | about 10m×1.8m× 1.5m (Depend on final design) |

| Shipping | 1X40GP container |

Advantages of the Roll Forming Machine

1. Anti-rust roller: The metalworking machinery is available with anti-rust forming rollers which are CNC machine tooled and plated with 0.05mm thick hard chrome.

2. Heat treatment: To avoid deformation of the cutting frame, special heat treatment is performed to eliminate the steel stress.

3. Cutter blade: The cutter blade for the roll forming machine is fabricated from Cr12 mould steel and comes with quenched treatment, which ensures long service life.

4. High precision: The metal fabrication equipment delivers very high precision, because of its CNC machined forming rollers and the roller shafts which are processed by grinding machine for at least twice.

5. User-friendly operation: Mitsubishi PLC control system with touch screen makes the sheet metal equipment easy for operation. User-friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifetime service is available for our roll forming machine.

-

Roller is made of high grade No.45 forged steel plated with hard chrome, by digital-controlled procession.

This machine can make products of different widths by adjusting the hand wheel. -

Panel width is adjustable.