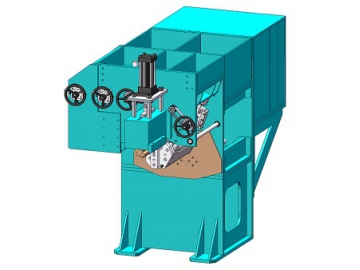

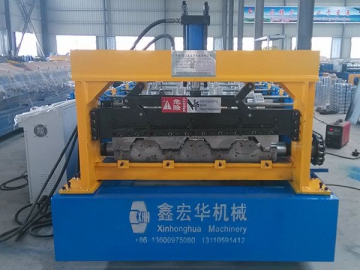

Roll Forming Machine (For Steel Floor Decks)

The roll forming machine is a popular range of sheet metal coil processing equipment for the production of steel floor decks. The metal decking produced by the metal forming machine comes with high strength, large spaces between waves, and adheres well to concrete. Used on high buildings, it not only saves the usage of steel form plates but also reduces the weight of storey. As compared with steel floor plates with the same bearing capacity, the steel floor deck fabricated by the roll forming machine can greatly reduce the usage of steel and thus cuts down users' investment cost accordingly.

Technical Data of the Roll Forming Machine| Suitable material | Q235 color steel sheet; 0.7-1.2mm, |

| Forming speed | about 15m/min |

| Power Requirement | Main motor power: 18.5 Kw (Depend on final design) |

| Hydraulic station power | 5.5Kw (Depend on final design) |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Shaft diameter | 82mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 16500KGS |

| Machine's size | about 26m×1.8m× 1.5m (Depend on final design) |

| Shipping | 1x40GP and 1X20GP containers can load one machine |

Advantages of the Roll Forming Machine

1. Heat treatment: The cutting frame of the roll forming machine undergoes special heat treatment to eliminate the steel stress, which effectively prevents frame deformation.

2. Anti-rust roller: The forming rollers for the sheet metal equipment have high precision and enhanced durability, because of CNC processing and 0.05mm thick hard chrome plating.

3. Cutter blade: The cutter blade is made of Cr12 mould steel and quenched to extend service life.

4. User-friendly operation: Due to Mitsubishi PLC control system with touch screen, the roll forming machine is easy for operation and supports user-friendly man-machine interaction.

5. High precision: While adopting CNC machine for forming roller processing, we also perform at least two times of precision grinding for the roller shafts. This provides the metal bending machine with improved accuracy.

6. Excellent services: Upon request, we can send technicians to our clients' factories, so as to assist in machinery installation and operator training. All our roll forming machines are available with lifetime service.

-

Roller is made of high grade No.45 forged steel plated with hard chrome, by digital-controlled procession. Solid shaft diameter is 82mm.

-

The machine has about 30 forming stations. The weight is about 15 tons.