Pressure Test Kit

- Portable Pressure Test Kit

- Portable Pressure Test Kit

As one of our newly developed products, the pressure test kit can be used for on-site pressure testing purpose in all kinds of machinery systems. It mainly includes the pressure testing hose, testing coupling, pressure gauge, and the wrench. Pressure gauge kits with varied specifications are available.

While widely used for hydraulic system pressure testing in engineering machinery, the pressure testing kit is also often found in industries such as steel making, automotive, shipbuilding, military, etc.

Advantages of the Pressure Test Kit

1. The hydraulic test kit is easy to carry due to its compact size. The outer box is fabricated from high strength environmental friendly plastic, and thus is lightweight and durable. It won't break even when it falls from 10 meters high.

2. The pressure testing kit includes 8 test couplings, 3 pressure testing hoses, 3 pressure gauges, and 1 wrench. The 8 couplings can meet most of your pressure testing purposes, and all the pressure gauges are imported from Germany. The additional configuration of wrench provides users much more convenience.

3. All connectors are white zinc plated and the plating layer features uniform thickness.

| ITEM | SIZE | Quantity |

| Pressure gauge | ¢ 63/G1/4-6Mpa | 1 |

| Pressure gauge | ¢ 63/G1/4-25Mpa | 1 |

| Pressure gauge | ¢ 63/G1/4-40Mpa | 1 |

| Test couping | M16*2;G1/8*28 | 1 |

| Test couping | M16*2;UNF7/16"*20 | 1 |

| Test couping | M16*2;G1/4*19 | 1 |

| Test couping | M16*2;M12*1.5 | 1 |

| Test couping | M16*2;M14*1.5 | 1 |

| Test couping | M16*2;UNF9/16"*18 | 1 |

| Test couping | M16*2;M16*1.5 | 1 |

| Test couping | M16*2;M10*1.0 | 1 |

| Test hose | length=1500mm, test fitting can be made according to customer's requirement | 3 |

| Wrench | length: 200mm | 1 |

Note: The pressure gauge and test coupling can be customized according to clients' demands.

Usage and Maintenance of the Pressure Test Kit

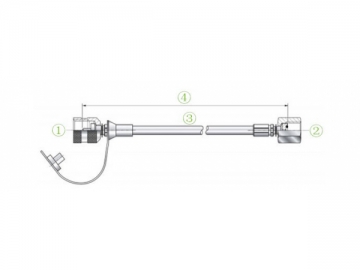

1. The test coupling should be fixed on the parts where the pressure is to be tested. The connecting thread of the test coupling should be coincident with that of pressure testing hose.

2. The pressure testing can be conducted when the hydraulic system is in operation. However, please make sure the max. system pressure is within the measurement range of pressure gauge.

3. During pressure testing, the pressure testing equipment should be placed levelly. The distance between the pressure testing point and testing equipment should be less than 85% of the pressure testing hose.

4. The test hose should be fixed on the corresponding pressure gauge connectors firstly, and then unscrew the dustproof cover on the test coupling. After that, fix the other end of the test hose onto the test coupling. Thus, pressure testing can be started.

5. After pressure testing, please firstly unfix the hose and the test coupling, and then screw on the dustproof cover. After that, unscrew the hose from the pressure gauge.

6. After testing, the oil stains on the pressure test kits should be cleaned carefully and don't forget to lock up the case.

7. Avoid collision and impact on the pressure test equipment. The pressure gauges should be inspected every half year.