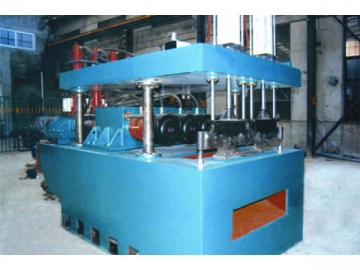

Hydrostatic Tester

Right after a welded pipe is produced, it needs to undergo a series of tests before leaving factory. The hydrostatic tester provides an easy, fast way to test the ability of the welded pipe to withstand hydrostatic pressure. Available with polyurethane face seals, the hydrostatic testing system holds the quality of each welded pipe to stringent API standards.

A key step in the hydraulic test is to maintain a balance between the oil pressure outside the pipe and the water pressure within it. This is done via an oil-water balance system. Test results are recorded, stored, and printed out using the computer.

Wanxin hydrostatic tester delivers maximum safety and reliability in pressure maintenance.

Hydrostatic testing process

Load tester with pipes-Connect pipes- Filling pipes with water - Charging pipes to preset pressure-Maintain pipe pressure-Release pipe pressure-Discharge of water-Unload pipes

| Item | Model No. | Pipe Diameter(mm) | Pipe Length(m) | Pressure (MPa) | Installed capacity (KW) | Floor area (m2) |

| 1 | Φ 25 ~Φ85 | 5~7 | ≤50 | 65 | 5 × 12 | |

| 2 | Φ 30 ~Φ114 | 5~7 | ≤50 | 65 | 5 × 12 | |

| 3 | Φ 40 ~Φ165 | 5~8 | ≤50 | 75 | 5 × 12 | |

| 4 | Φ 165 ~Φ325 | 6~12 | ≤42 | 85 | 4×20 | |

| 5 | Φ 21 9~Φ630 | 8~12 | ≤21 | 65 | 4 × 2 2 | |

| 6 | Φ 219 ~Φ820 | 8~12 | ≤21 | 85 | 4 × 2 2 | |

| 7 | Φ 426 ~Φ1420 | 8~12 | ≤21 | 100 | 4 × 2 2 | |

| 8 | Φ 5 29 ~Φ1820 | 8~12 | ≤21 | 120 | 4 × 2 5 | |

| 9 | Φ 82 0 ~Φ2500 | 8~12 | ≤21 | 160 | 6 × 30 | |

| 10 | Φ 1020 ~Φ3500 | 8~12 | ≤15 | 160 | 8 × 30 |