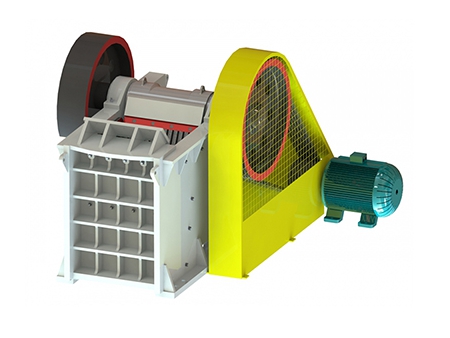

Jaw Crusher

The jaw crusher, a heavy duty machine which crushes stones, coal, and other materials into small, even pieces, features a high reduction ratio for high productivity. The stone jaw crusher's, simple structure and reliable performance makes it convenient to maintain and practical to use. The coal jaw crusher is used in mining, metallurgy, construction, smelting, road building, and chemical industries for crushing material with compressive strength not more than 320 MPa.

Features

1. A deep crushing chamber has no dead space, increasing the feeding capacity and productivity.

2. A high reduction ratio makes for small and even granules of crushed materials.

3. The mining equipment has a reliable and convenient gasket dispensing device with an adjustable and wide opening for use in a range of situations.

4. A self-lubricating system means little maintenance is needed. Accessories are convenient to replace.

5. With a simple structure, the jaw crusher has a low operating cost and low noise.

6. A single coal crusher saves about 15% to 30% energy and a whole system saves more than double of that.

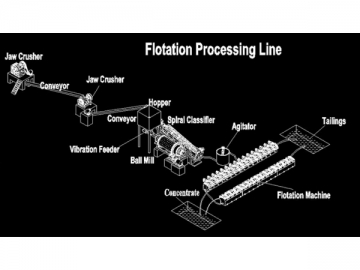

Working Principle

The jaw crusher is made up of a frame, eccentric shaft, belt wheel, flywheel, movable jaw, side guard plate, toggle plate for safety, toggle backseat, gap adjusting screw, returning spring, fixed jaw plate and movable jaw plate. An electric motor powers the machine, driving the eccentric shaft to control the movable jaw. The fixed and movable jaw plates and the edge plate, which make up the crushing chamber crush materials into fine pieces and dispense them.

| Specification and Model | Technical Features | Motor power ( kw ) | Dimension (L× W× H) (mm) | Weight (kg) | |||

| Max. feeding size (mm) | Adjustment range (mm) | Production capacity (m 3 /h) | Rotating speed of main shaft (r/min) | ||||

| 125 | 10-40 | 1-3 | 285 | 7.5 | 922×745×933 | 700 | |

| 165 | 20-70 | 2-8 | 265 | 11 | 1056×1100×1120 | 800 | |

| 210 | 20-80 | 5-20 | 310 | 18.5 | 1108×1142×1392 | 3000 | |

| 340 | 40-90 | 10-40 | 275 | 30 | 1700×1732×1392 | 7200 | |

| 290 | 30-55 | 20-50 | 300 | 37 | 1900×1806×1808 | 8900 | |

| 425 | 50-100 | 34-68 | 275 | 55 | 2050×1860×2145 | 11320 | |

| 480 | 75-200 | 40-120 | 255 | 75 | 2792×2168×2250 | 17600 | |

| 630 | 80-200 | 80-160 | 250 | 90 | 4180×2560×3070 | 30530 | |

| 750 | 100-200 | 110-200 | 250 | 110 | 5200×2900×3500 | 50000 | |

| 1020 | 150-300 | 220-400 | 180 | 160 | 4200×3300×3500 | 106000 | |

| 125 | 10-40 | 5-15 | 300 | 15 | 1220×1480×1180 | 3600 | |

| 210 | 15-55 | 10-32 | 300 | 37 | 1580×1992×1380 | 7350 | |

| 210 | 15-60 | 12-38 | 300 | 37 | 1530×2192×1380 | 8700 | |

| 250 | 20-90 | 16-65 | 300 | 55 | 1930×2400×1747 | 11600 | |

Note: These specifications are just for reference. Changes vary among products.