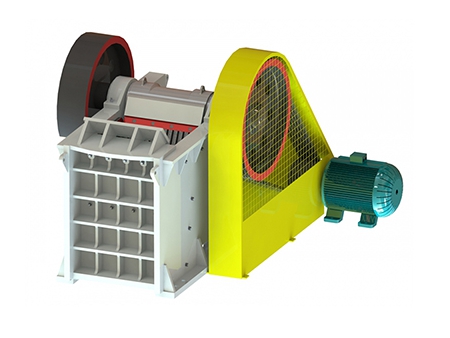

Jaw Crusher (Deep Cavity)

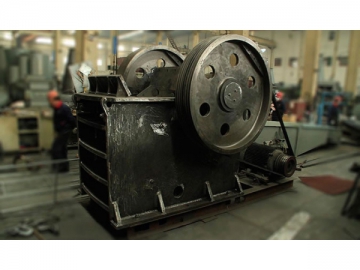

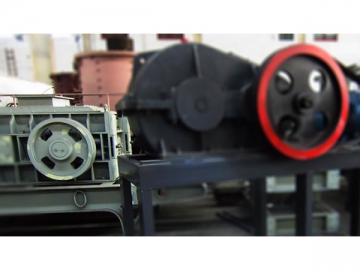

PE series jaw crusher is a new type of crushing machine developed by Dingbo. Its crushing cavity consists of movable jaw plate and fixed jaw plate. It has the advantages of simple structure, reliable work, easy maintenance and low construction cost. This crusher is widely used for crushing all kinds of ores and bulk materials in mining, building materials, roads, railways, water conservancy and chemical industries. The highest compressive strength of the crushed material is 320Mpa.

Working Principle

Our crushing machine crushes the materials by extrusion, the working principle is to simulate the movement of two jaws of the animal. The drive belt and belt pulley are driven by motor, the movable jaw is moving up and down through the eccentric shaft. When the movable jaw goes up, the angle between toggle plate and movable jaw becomes large, so as to push the movable jaw plate close to the fixed jaw plate, the materials are crushed by extruding, rolling, and grinding through the two jaw plates. When the movable jaw goes down, the angle between toggle plate and movable jaw becomes small, the movable jaw plate leaves the fixed jaw plate by the action of pull rod and spring, and the crushed materials are discharged from the discharge port by the action of gravity.

Application

These crusher machines are designed to crush hard materials such as granite, marble, basalt, limestone, quartz, iron and copper ores.

Features

1. Crushing cavity is deep and no dead zone, that can improve the feeding capacity and output of jaw crusher.

2. Large crushing ratio and uniform granularity.

3. Lubricating system is safe and reliable, it is convenient to replace the spare parts, and easy to maintain.

4. Simple operation, reliable work and low cost.

5. This crushing equipment is energy saving, the single unit can save the energy 15%-30%, the system can save the energy saving more than doubled.

Notes

1. The common problem of jaw crusher is the amount of material feed which is not uniform during feeding process, especially when the feed quantity is suddenly increased, the motor will be burnt out caused by too large load.

2. You have to stop feeding material when you want to stop running the crusher. Because there are too many unprocessed ore materials inside of the crusher that will cause damage to the machine parts if stop running before feeding, at the same time, the load of the crushing machine will be too large.

| Model | Feed Opening(mm) | Max Feeding(mm) | Discharge Opening (mm) | Capacity(t/h) | Power(kw) | Machine Size (mm) |

| 400×250 | 200 | 20-50 | 5-20 | 15 | 1430×1310×1340 | |

| 600×400 | 350 | 40-100 | 15-60 | 30-37 | 1700×1732×1653 | |

| 500×750 | 425 | 50-100 | 40-110 | 45-55 | 2035×1921×2000 | |

| 900×600 | 480 | 65-160 | 90-180 | 55-75 | 2290×2206×2370 | |

| 1060×750 | 630 | 80-140 | 110-320 | 90-110 | 2655×2302×3110 | |

| 900×1200 | 750 | 95-165 | 220-450 | 110-132 | 3800×3166×3045 | |

| 1000×1200 | 850 | 195-265 | 315-550 | 110-132 | 3800×3166×3045 | |

| 1200×1500 | 1020 | 150-300 | 400-800 | 160-220 | 3800×3166×3045 | |

| 150×250 | 125 | 10-40 | 1-3 | 5.5 | 896×745×935 | |

| 150×750 | 125 | 18-48 | 5-16 | 15 | 1200×1500×1200 | |

| 750×250 | 210 | 25-60 | 15-30 | 22-30 | 1667×1545×1020 | |

| 1000×250 | 210 | 25-60 | 15-50 | 30-37 | 1550×1964×1380 | |

| 1200×250 | 210 | 25-60 | 20-60 | 37-45 | 2192×1900×1950 |

Note: all technical specification are based on relevant standards, and additional changes can be made upon request.

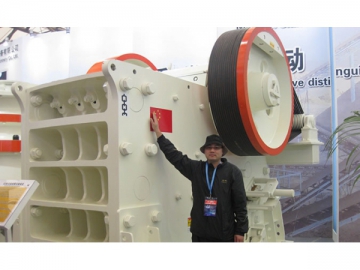

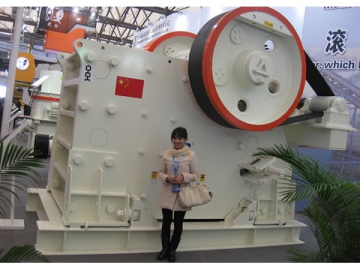

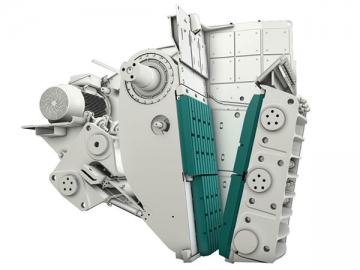

In Exhibition