High Pressure Suspension Mill

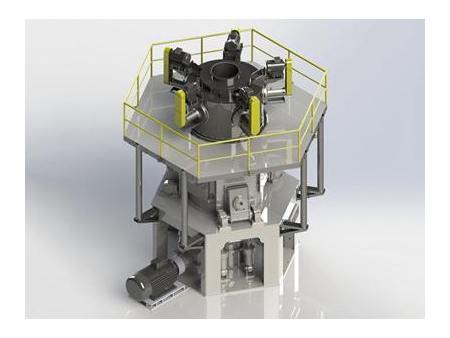

High pressure suspension mill is designed and updated on the basis of Raymond mill. It is suitable for processing non flammable and explosive mineral which Mohs scale of mineral hardness is less than 9.3, and humidity is below 6%. This grinding mill is widely used in metallurgy, building materials, chemical, mining, highway construction, water conservancy and hydropower, and other industries. It is also an ideal equipment for processing quartz, feldspar, calcite, limestone, talc, ceramics, marble, granite, dolomite, bauxite, iron ore, barite, bentonite, coal gangue, coal and other materials. Compared with ball mill, this high pressure mill has lower power, lower power consumption, smaller floor area and lower investment cost.

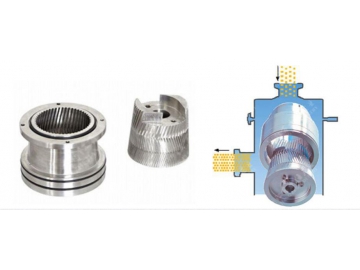

The roller is grinded tightly on the grinding wheel under the action of centrifugal force, so that the grinding roller, grinding wheel will not affect the output and fineness of the finished product even they have been worn to a certain thickness. The grinding roller, grinding wheel and other quick-wear parts have long service life. The finished granularity is within 80-425mesh according to the request (maximum fineness can reach 1000mesh), this grinding mill also can produce 30-80 mesh coarse powder by adding a special device.

Working Principle

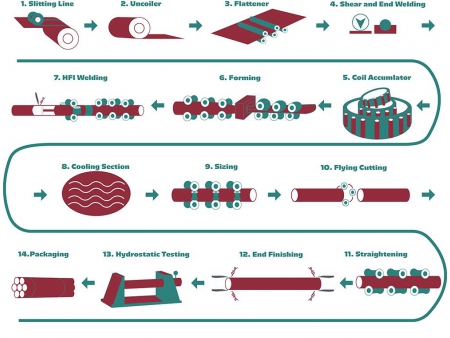

General: Crushing -- Grinding -- Selecting -- Collecting

Detailed: The high-pressure mill has the same working principle as the Raymond Mill, but its grinding fitting is furnished with a 1000 - 1500 kg pressure spring.

When the grinding device is in operation, the grinding roll, under the action of a high pressure spring and centrifugal force rolls along the grinding ring. Its rolling pressure ratio is 1.2 times that of the Raymond mill in identical conditions, and has a 10-20% higher output. The pressure spring must be adjusted when the ring reaches a certain degree of abrasion to achieve stable output.

Features

1. 10-20% higher output compared to the Raymond mill in similar conditions.

2. Output size range of 0.613mm (30mesh) –0.033mm (425mesh). Some materials can be ground to 0.013mm (1000 mesh)

3. Excellent dust control. Meets all dust output standards.

4. Easy to operate. The machine can also work well in conjunction with other systems.

5. Outstanding sealing with multi-class seals.

| Type | Roller | Max. feeding size(mm) | Fineness of product(mm) | Output (t/h) | Power (KW) | Size(mm) | ||

| No. | Dimension (mm) | Height (mm) | ||||||

| 3 | 260 | 150 | 20 | 0.613-0.045 | 0.5-3 | 18.5 | 4300×3500×5100 | |

| 3 | 270 | 140 | 20 | 0.613-0.045 | 1.2-4.6 | 22 | 4300×3500×5100 | |

| 4 | 310 | 170 | 25 | 0.613-0.045 | 2.1-8 | 37 | 7100×5900×7900 | |

| 5 | 410 | 210 | 30 | 0.613-0.045 | 5-11 | 75 | 9200×7250×9700 | |

| 6 | 440 | 270 | 30 | 0.613-0.045 | 8-22 | 132 | 12550×5750×8355 | |

| 5 | 520 | 280 | 40 | 0.6-0.045 | 13-25 | 160 | 12275×9555×9916 | |