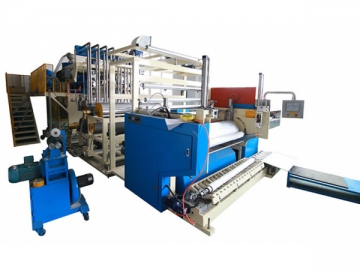

Stretch Film Extruder

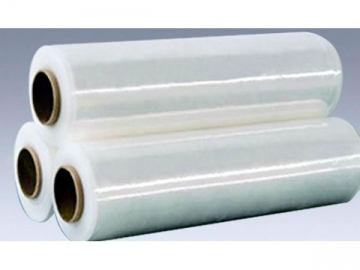

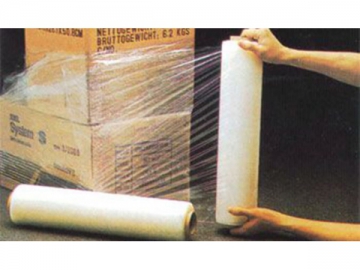

The stretch film extruder, taking PE and PP granules as raw material, is used to produce packaging films through heating, melting and screw extrusion processes. PE or PP films made in this film extrusion line come with a width of 1500mm. With further slitting and rewinding process, they can be made into three same film rolls with a width of 500mm.

The PE film extruder comprises three extrusion machines, and it can produce a three-layer co-extrusion stretch film. Due to raw material metering pump technology, the product can realize the effect of seven-layer or eight-layer stretch films made by other equipment. Production capacity is up to 300kg/h.

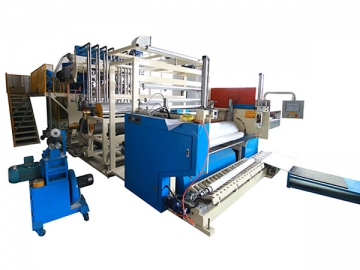

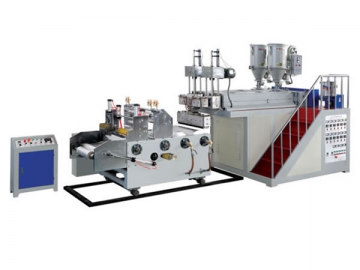

Features of the Stretch Film Extruder

1. Cooling Roller

The film co-extruder uses large diameter cooling roller with special runner, thus effectively improving cooling effect in high speed production and ensuring uniform temperature on the cooling roller.

2. Extrusion Screw

Extrusion screw of the stretch film extruder is made of special alloy and comes with high melting point. It ensures that the film boasts higher stability, uniformity, transparency, tensile strength and viscidity.

3. Fully Automatic Production

The plastic film production line is characterized by fully automatic production. It is designed with metering pump for auto feeding, automatic rewinding roll changing device, mechanical arm for automatic air shaft loading, automatic paper core feeding device and automatic unloading unit so as to guarantee high speed, high capacity and minimize production cost and maximize efficiency.

4. Famous Brand Electrical Parts

All electrical parts of the stretch film extruder are from well renowned suppliers both at home and abroad, thus ensuring stable running and low fault rate.

5. Melt Metering Pump Technology

Melt metering pump technology enables stable and efficient pressure control, shortens feeding time, improves product output and quality, and extends machine's service life.

| Screw diameter (mm) | 70, 90, 100 (as customer needs) |

| Screw length diameter ratio | 30:1 |

| Die head width (mm) | 1850 |

| Finished film width (mm) | 1500 |

| Finished film thickness (mm) | 0.01-0.05 |

| Film structure | A/B/C A/C/B/C/A |

| Total power ( KW ) | 30-150 |

| Maximum capacity ( kg/h ) | 300 |

| Max. speed (m/min) | 150 |

| Paper core loading method | Automatic loading to airshaft and air inflating |

| Rewinding roll changing method | Pneumatic film feeding and automatic roll changing |

| Film roll unloading method | Automatic deflating of airshaft and automatic unloading |

| Weight | 1.3 t |

| Dimension (mm) | 2000m m ×4000mm×4000mm (L×W×H) |