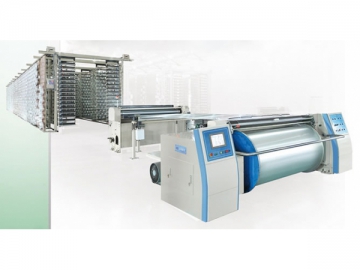

Sizing Machine, JT600

Textile Sizing Machine | Textile Machine | Max. Sizing Speed 400m/min, Working Width 1780mm

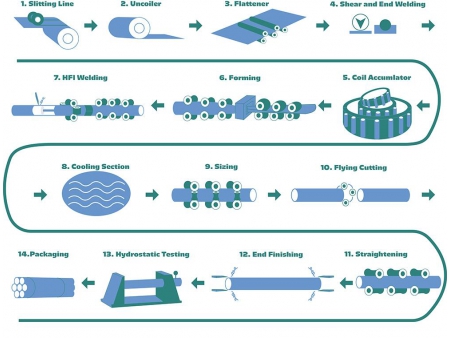

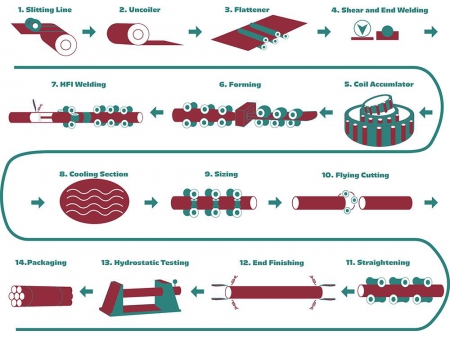

Features of the Sizing Machine

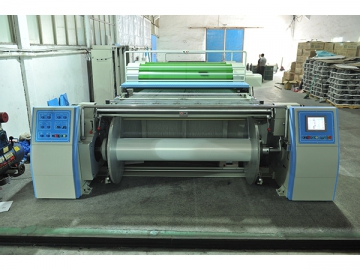

1. High precision low tension speed control system makes tension control more stable.

2. The warp sizing system features multi-unit transmission by vector motor, achieving stable elongation control.

3. It adopts high pressure sizing method, with pressure automatically controlled according to yarn's leaner speed.

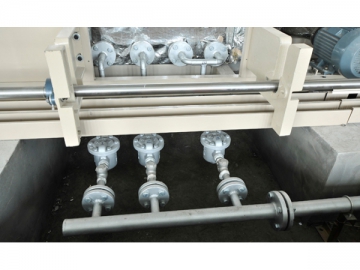

4. Circulating cooling water flows through the split rods to prevent sizing agent from being solidified.

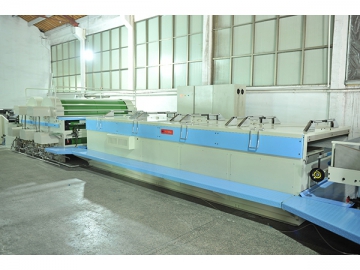

5. The sizing machine for filament yarns employs high speed and energy saving drying oven which ensures not only high speed and high temperature drying but also low temperature and flexible drying.

6. Hot air circulating system comes with variable frequency control, thus greatly improving drying efficiency.

7. High speed and low vibration cylinder provides automatic temperature regulation.

8. The weaving equipment is provided with a cooling chamber that can considerably reduce bubbles generated on the sized yarns.

9. During acceleration and deceleration, it can run with quiet stable tension.

Product Details (Textile Machine Spare Parts)

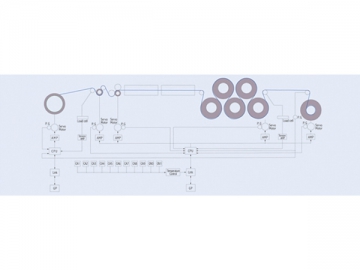

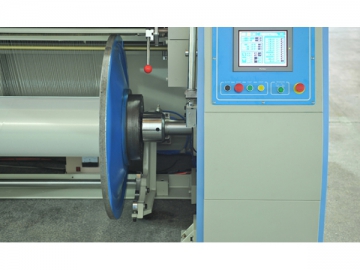

Various technical parameters can be preset on the human-machine interface; real time monitoring of change of each parameter during operation.

This textile sizing machine shows its running status by a diagram. When there is a fault or alarming in running, it can display the fault information and guide the operator to handle it.

Touch to operate

State of the art electronic technology enables this sizing machine to realize precise low tension control in unwinding and winding and conduct gentle sizing to extra fine yarns.

The feeding and winding sections adopt AC motor to realize real time tension control, ensuring extra precise tension control when accelerating or decelerating and stopping.

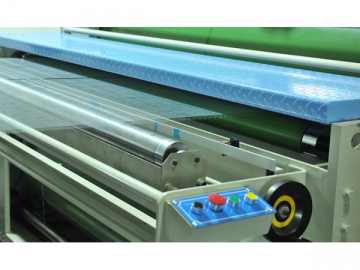

The textile equipment applies waxing unit that is a roller controlled by a variable speed motor

Yarn breakage sensor ensures the sizing machine can stop instantly when a yarn is broken.

A steam traps system can considerably reduce steam consumption while making the drying oven reach preset temperature.

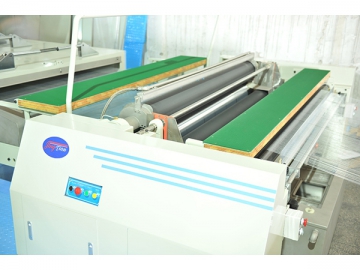

Squeezing roller is used to carry out even squeezing to the sizing agent on the yarns, thus ensuring high quality sizing. In addition, due to reasonable roller allocation and combination with stock tank, splashing and bubbling can be effectively avoided.

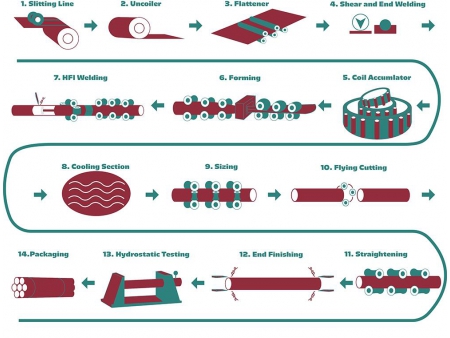

| TYPE | |

| Max. sizing speed | 400m /min |

| Working width | 1780mm |

| Sizing rollers | 1680 |

| Elongation control method | Multi-section drive method |

| Sizing method | Double squeezing roller |

| Immersion roller diameter | Φ 190mm |

| Sizing roller diameter | Φ 230mm |

| Squeezing roller diameter | Φ 220mm |

| Squeezing roller structure | Even squeezing |

| Max. squeezing load | 15KN |

| Drying method | Hot air and heating cylinder |

| Temperature control | Automatic temperature control system |

| Number of cooling device | 4 4 |

| Drying oven length | 5 5 m |

| Electric heating | Optional |

| Number of heating cylinder | 5 |

| Waxing unit | Waxing roller |

| Cooling system | Air circulation |

| Drive motor | EUROTHERM AC vector motor |

| Winding tension control method | AC vector motor feedback control |

| Winding tension control range | 8-30kg |

| Unwinding tension control range | 6-20kg |

| Dryer standard configuration | High efficiency hot air supply device with filter; frequency converter |

| Air conditioning in the cooling chamber | Standard configuration |

| Air conditioning for creel | Standard configuration |

| Yarn breakage sensor | Standard configuration |

| Tension automatic detector in drying oven | Optional |

| Steam filling amount | 700kg /h |

| Steam consumption | 600kg /h |

| Total length | 23165mm |