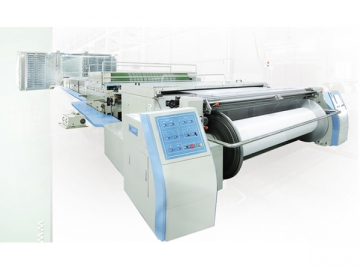

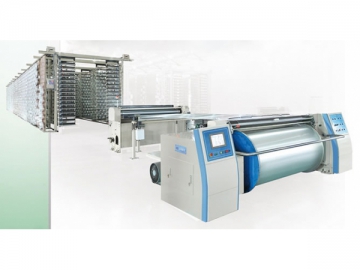

Sizing Machine (with Warping Function), JT450

Sizing Machine | Equipment for Textile | Max. Sizing Speed 450m/min, Working Width 2750mm

Features

1. Drive shaft is used for stable tension control.

2. The beam creels are directly connected to the sizing equipment, thus saving labor, time and space.

3. Creel number of the warping and sizing machine can be twice as normal.

4. Working width is up to 2750mm and more.

5. It is suitable for loom beams in 920mm diameter.

6. Design speed reaches the maximum 450m/min.

7. The largest winding tension is 100kg.

Product Details

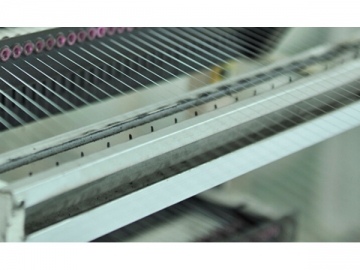

1. Using 5 1 type leasing rods, the textile sizing machine is available to reserve yarns, making sure that it can restart quickly when encountering yarn breakage.

2. Auto stop device is designed on the creels to control the machine to stop automatically when yarns are broken.

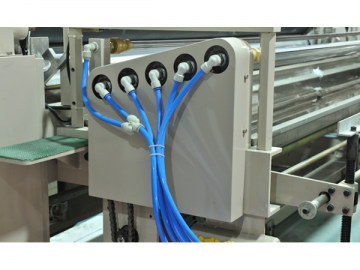

3. The warping and sizing machine comes with an anti-static device that can eliminate the static caused by the friction of yarns

4. Maximum working width of the drying tunnel is up to 2000mm (1960 pieces of yarns). This ensures fewer warp beams on the beam creels and a 20% increase of comprehensive productivity.

5. Combination of heating cylinder and drying tunnel allows the largest working width to reach 3000mm. The more the yarns are put onto the machine, the fewer warp beams on the creel. So, the comprehensive productivity is able to be increased by 50%. The yarns are evenly separated by multi-layer leasing rods and are dried in the drying tunnel by non-contact drying method, thus ensuring smooth beam surface and maintaining yarns' original characteristics.

6. Working width of the sizing machine is more than 2750mm, considerably improving its production efficiency and thereby improving looms' efficiency.

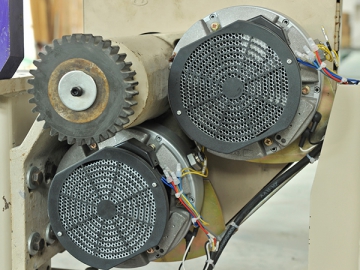

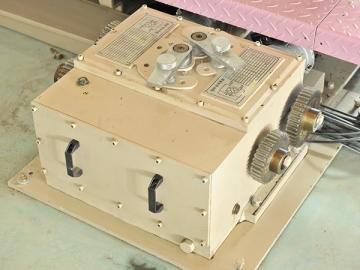

Other Components

Technical Parameters of the Warping and Sizing Machine

Download PDF

| TYPE | A Type |

| Creel | Low configuration |

| Yarn breakage auto stop device | IR auto stop |

| Static eliminating device | Standard configuration |

| Max. speed | 400m /min |

| Working width | 1780mm |

| Sizing capacity (Yarns number) | 1680 |

| Tension control method | Drive shaft control |

| Sizing method | Double squeezing roll |

| Immersion roll diameter | Φ 180mm |

| Sizing roll diameter | Φ 200mm |

| Squeezing roll diameter | Φ 190mm |

| Squeezing roll structure | A structure for even squeezing |

| Max. load on squeezing roll | 15KN |

| Drying method | Hot air in drying tunnel, heating cylinder |

| Temperature control system | Automatic temperature control |

| Drying room number | 2 |

| Heating cylinder number | 5 |

| Waxing device | Optional |

| Leasing rod cooling system | Active cooling system |

| Frequency converter | EUROTHERM |

| Winding tension control method | AC vector motor feedback control |

| Winding tension control range | 20-100kg |

| Drying room standard configuration | High efficiency hot air supply device with filter, controlled by frequency converter |

| Air conditioning in the cooling room | Optional |

| Yarn breakage sensor | Optional |

| Stream trap | Made in China |

| Pressure reducing valve | Made in China |

| Safety valve | Made in China |

| Electromagnetic valve | Made in China |

| TYPE | B Type |

| Creel | Standard configuration |

| Yarn breakage auto stop device | Contact type auto stop |

| Static eliminating device | Standard configuration |

| Max. speed | 420m /min |

| Working width | 2400mm |

| Sizing capacity (Yarns number) | 2300 |

| Tension control method | Drive shaft control |

| Sizing method | Double squeezing roll |

| Immersion roll diameter | Φ 190mm |

| Sizing roll diameter | Φ 230mm |

| Squeezing roll diameter | Φ 220mm |

| Squeezing roll structure | A structure for even squeezing |

| Max. load on squeezing roll | 15KN |

| Drying method | Hot air in drying tunnel, heating cylinder |

| Temperature control system | Automatic temperature control |

| Drying room number | 2 |

| Heating cylinder number | 5 |

| Waxing device | Standard configuration |

| Leasing rod cooling system | Active cooling system |

| Frequency converter | EUROTHERM |

| Winding tension control method | AC vector motor feedback control |

| Winding tension control range | 20-100kg |

| Drying room standard configuration | High efficiency hot air supply device with filter, controlled by frequency converter |

| Air conditioning in the cooling room | One Midea 5P Air Conditioning |

| Yarn breakage sensor | Standard configuration |

| Stream trap | Made in Korea |

| Pressure reducing valve | Made in Korea |

| Safety valve | Made in Korea |

| Electromagnetic valve | Made in China, or Imported |

| TYPE | C Type |

| Creel | Standard configuration |

| Yarn breakage auto stop device | Contact type auto stop |

| Static eliminating device | Standard configuration |

| Max. speed | 450m /min |

| Working width | 2750mm |

| Sizing capacity (Yarns number) | More than 2800 |

| Tension control method | Drive shaft control |

| Sizing method | Double squeezing roll |

| Immersion roll diameter | Φ 190mm |

| Sizing roll diameter | Φ 230mm |

| Squeezing roll diameter | Φ 220mm |

| Squeezing roll structure | A structure for even squeezing |

| Max. load on squeezing roll | 15KN |

| Drying method | Hot air in drying tunnel, heating cylinder |

| Temperature control system | Automatic temperature control |

| Drying room number | 3 |

| Heating cylinder number | 5 |

| Waxing device | Standard configuration |

| Leasing rod cooling system | Active cooling system |

| Frequency converter | EUROTHERM |

| Winding tension control method | AC vector motor feedback control |

| Winding tension control range | 20-100kg |

| Drying room standard configuration | High efficiency hot air supply device with filter, controlled by frequency converter |

| Air conditioning in the cooling room | Two Midea 5P Air Conditionings |

| Yarn breakage sensor | Standard configuration |

| Stream trap | Imported |

| Pressure reducing valve | Made in Korea |

| Safety valve | Made in Korea |

| Electromagnetic valve | Made in Japan |