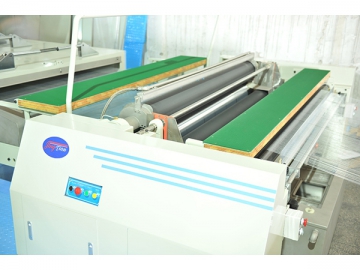

Beaming Machine

Beam Machine for all Weaving Applications | Manufacturing Machinery for Textile | Max. Speed 10-150mm/min, Working Width 2.3m

Our beaming machine makes warp beam directly rewound in virtue of stable winding tension control and AC vector motor. Utilizing feedback control from tension control motor, it achieves automatic winding tension control and makes it up to required tension. According to the characteristic of warp yarns, it adopts cone-shaped tension control technology. The unwinding speed of warp beam is directly measured by a speed measuring motor on the third beam creel and is automatically controlled by PLC and MC circuit board. This is convenient for the air cooling magnetic powder brake to carry out constant tension control to yarns. The winding tension can be up to 1000kg.

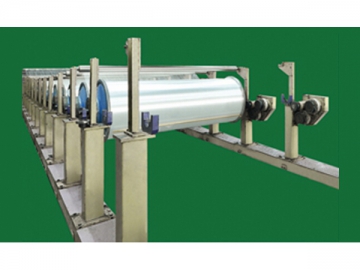

Single Layer Beam Creel

Single Layer Beam Creel Double Layer Beam Creel

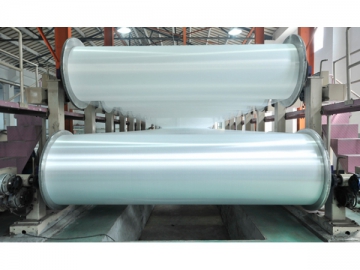

Double Layer Beam Creel Double Layer Beam Creel

Double Layer Beam Creel Double Layer Beam Creel

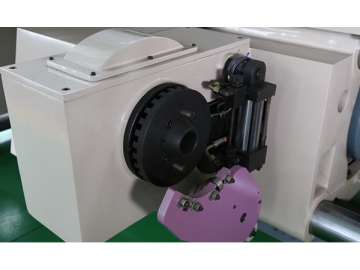

Double Layer Beam Creel Automatic Loading and Doffing Device

Automatic Loading and Doffing Device Control Panel (10.4 inch Pro-face Touch Screen)

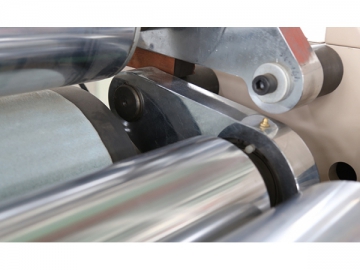

Control Panel (10.4 inch Pro-face Touch Screen) Tension Roller

Tension RollerFeatures of the Beaming Machine

1. The weaving machinery is designed with a device to prevent over-rotation when stopping and a power supply unit for use at power cut.

2. The beam supporting stand can move freely by means of screw rod driven by motor, and it can be loaded and unloaded automatically under the function of hydraulic power unit.

3. Maximum winding tension can be up to 1500KG, and the number of beam creels can reach 28. Normally, the beaming machine is provided with 12 beam creels and features 800KG winding tension.

4. The beamer is equipped with tension sensors and encoders on beam creels from the third to the last. They are automatically controlled by PLC, enabling air cooling magnetic powder brake to carry out constant tension control to yarns.

5. The beam creel is specially designed to keep same distance between each layer of yarns. Therefore, it ensure less prone to a knot.

Technical Parameters of the Beaming Machine

Download PDF

| TYPE | A Type Beaming Machine |

| Unwinding tension measuring method | Measured by balancing device |

| Unwinding driving method | Gear drive |

| Beam creel number | 8 or 12 |

| Beam creel layers | Single layer |

| Max. speed | 10-150mm/min |

| General working width | 2.3m |

| Max. tension | 800kg |

| Cone-shape tension | 0-30% |

| Loading and doffing device | Hydraulic |

| Main motor | 30kw (37kw) |

| Tension motor drive method | Belt drive |

| Guide roller | Optional |

| Display system | Touch screen/ Data memory system |

| Unwinding brake system | Air cooling magnetic powder brake |

| Unwinding tension control | 100-390N (with 1 magnetic powder brake) |

| 100-780N (with 2 magnetic powder brakes) |

| TYPE | B Type Beaming Machine |

| Unwinding tension measuring method | Measured by sensor |

| Unwinding driving method | Gear drive |

| Beam creel number | 12 |

| Beam creel layers | Single layer and double layer |

| Max. speed | 10-150mm/min |

| General working width | 2.3m |

| Max. tension | 1000kg |

| Cone-shape tension | 0-30% |

| Loading and doffing device | Hydraulic |

| Main motor | 30 kw |

| Tension motor drive method | Gear box |

| Guide roller | Optional |

| Display system | Touch screen/ Data memory system |

| Unwinding brake system | Air cooling magnetic powder brake |

| Unwinding tension control | 100-390N (with 1 magnetic powder brake) |

| 100-780N (with 2 magnetic powder brakes) |