Pyrolysis Plant / Recycling Machine

Tire pyrolysis is a very clean process as it produces no emissions or waste when performed well. With millions of tires going to waste every year, the tire pyrolysis plant is undoubtedly a valuable method for disposing scrap tires.

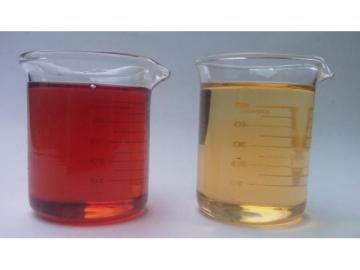

As waste tires are heated in the reactor, rubber polymers in them are broken down into smaller molecules. These molecules go on to vaporize and exit the reactor as a gas (with its composition pretty similar to natural gas). That gas can be further condensed into oil, which is a mix of diesel, kerosene, and heavy fuel oil, among other oil types. That being said, the tire pyrolysis plant can be a tire-to-oil pyrolysis unit that turns waste tires into sellable oil.

Tire pyrolysis installation in Thailand

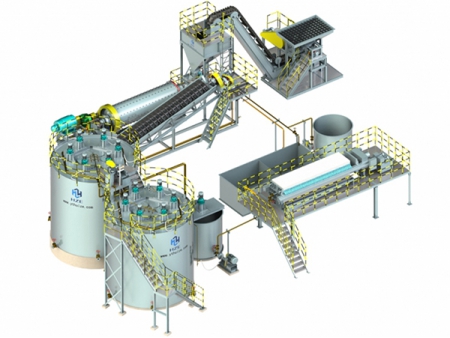

Tire pyrolysis installation in ThailandScrap tires aside, this pyrolysis plant also takes plastic and rubber waste. The plant is usually a massive unit that takes up a floor space from 300 to 600 square meters depending on the specific model and configurations customers choose.

Depending on your local market demand and tire availability, the pyrolysis unit can either do batch production or operate continuously without stop. The system can be fed automatically, or by workers if a manual model is your choice. Operating an automatic unit typically requires 2 workers, whereas the manual model takes 4 workers to attend to. We design turnkey pyrolysis plants in 5 ton, 8 ton, 10 ton, and 20 ton capacity. Several pyrolysis units can work in tandem as well to bring about a daily yield of 100 tons.

Materials suitable for pyrolysis include:

Scrap tire

Plastic waste (such as PE, PVC, etc.)

Rubber waste (shoe soles, cable sheath)

Oil sludge,

Note that materials used for pyrolysis may vary, but the tire rubber pyrolysis plant for them is the same, with the only difference being the pyrolysis process. Concerning that, we'll provide free operator training courses. You may as well send us material samples, and based on that we can test how much percentage oil your material can yield.

Products from Rubber Pyrolysis| Serial No. | Products | Percentage Yield | Uses |

| 1 | Oil | 45% | Sell it out directly. Distill it into petrol and diesel via distillation equipment. Burn it to produce power. |

| 2 | Carbon Black | 30% | Can be sold. Turned into refined carbon black by carbon refining equipment . Made into carbon black pellets using a carbon black pelletizer . |

| 3 | Steel Wire | 15% | Sells as a product. Compresses into bales with a hydraulic press for easy transportation and storage. |

| 4 | Gas | 10% | Uses as fuel in a gas-fired flame gun. Stored in a tank. |

| Serial No. | Model No. | Dimensions (mm) | Handling Capacity | Handling Speed | Power |

| 1 | 2200×6000 | 5-6 t/cycle | 2 days for 3 cycles | 13 kw | |

| 2 | 2200×6600 | ||||

| 3 | 2400×6000 | 6-7 t / cycle | 2 days for 3 cycles | 15 kw | |

| 4 | 2400×6600 | ||||

| 5 | 2600×6000 | 8-9 t/cycle | 1 cycle per day | 20 kw | |

| 6 | 2600×6600 | ||||

| 7 | 2800×6000 | 10 t/cycle | 1 cycle per day | ||

| 8 | 2800×6600 | 12 t/cycle | 1 cycle per day |

| Serial No. | Model No. | Loading Time | Pyrolysis Time | Cooling Time | Discharge Time |

| 1 | 1-2 hours | 7-9 hours | 2 hours | 1 hour | |

| 2 | |||||

| 3 | 1-2 hours | 9-10 hours | 2 hours | 1 hour | |

| 4 | |||||

| 5 | 2-3 hours | 10-12 hours | 2-3 hours | 1-2 hours | |

| 6 | |||||

| 7 | 2-3 hours | 12-14 hours | 2-3 hours | 1-2 hours | |

| 8 |

| Serial No. | Fuels | Ancillary Combustion Equipment |

| 1 | Coal | Furnace grate |

| 2 | Wood | Furnace grate |

| 3 | Oil (fuel oil, tire-derived oil, plastic-derived oil, heavy fuel oil) | Oil-fired flame gun |

| 4 | Natural Gas | Gas-fired flame gun |

| 5 | Electricity | electric furnace heat strip |

| 6 | Carbon Black Particles | Carbon black pelletizer is available. |

Service

On-site Installation

We send our technicians to your site for field installation, commissioning and operator training. Clients should provide board and lodging. Installing one pyrolysis unit takes about 25 days.

Lead Time

Normal lead time is around 20 days.

Repair and Replacement Policy

Parts are repaired free of charge within 2 years, excluding normal wear parts. We'll replace the equipment that can't be repaired if the problem is due to manufacturing fault.

Turnkey Project

Our turnkey project helps pyrolysis plant buyers save time and labor as well as brings their production up to speed.

India Installation

India Installation Bangladesh Installation

Bangladesh InstallationYilong is an expert on waste disposal and recycling equipment. We are proud to announce that our tire to oil pyrolysis unit has passed SGS emission tests, EPA tests, and CE certification. The facility is highly praised for its high level of automation and maximum oil yield. We welcome customers around the world to take a guided tour around our factory.