Biodiesel Processor

Yilong is a trusted name in waste disposal and recycling solution. Over the course of development, we are very proud to present this biodiesel processor to eco-conscious customers. The biodiesel production equipment provides a great way to reuse your waste oil collected from restaurants, home kitchens and food factories. With Yilong biodiesel processor, you can turn your used cooking oil, vegetable oil, animal fats and restaurant grease (either in high or low fatty acid value) into valuable biodiesel to replace traditional diesel used in vehicles.

Operating Principle

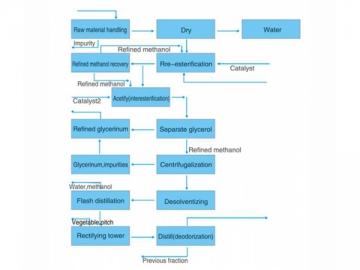

Biodiesel production is a complicated process that uses both esterification and transesterification reactions to produce methyl esters (biodiesel). All feedstocks (fats and oils, or lipids) purchased from industrial sources contain more or less fatty acids that tend to consume the basic catalysts used for catalyzing the transesterification reaction. To remove those fatty acids, we've introduced the esterification process. The resulting biodiesel may still contain some impurities, which is why it needs to undergo distillation to ensure the final product meets industrial standards.

Note that fats and oils are mainly composed of triglycerides (three fatty acid molecules attached to one glycerol molecule). In waste oils and fats, many triglycerides have broken down into separate fatty acids and glycerol. That is why fatty acids can be found in the feedstocks.

Biodiesel Production Process Flow

There is a lot waste oil to be found for free that can be used in biodiesel production. Below we only list some of it.

| Serial No. | Feedstocks | Note |

| 1 | Slaughterhouse scraps | From slaughterhouse |

| 2 | Gutter oil | Waste cooking oil |

| 3 | Fatty acids, acidic oil from refining factory | Bean and coconut oil, for example. |

| 4 | Palm oil & Vegetable oil, etc. | / |

| Despite the variety of waste oil to be used, the biodiesel processor employed for handling them is the same, though the production process and catalysts may vary as well. Since there is too much to consider, our technicians can offer training courses for machine operators. | ||

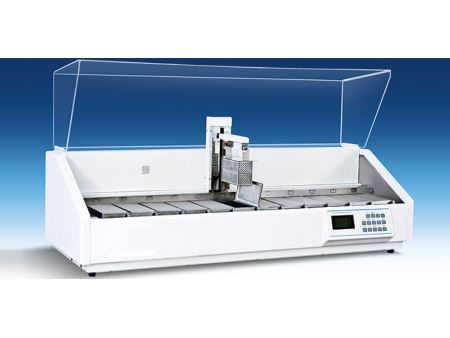

Biodiesel Processor Parameters

1. Feedstock Viscosity (20℃) (kg/m2): 0.82-0.9

2. Kinematic viscosity of sulfuric acids (40℃) (m/m2): 1.9-6.0

3. Closed cup flash point: ≥130℃

4. Freezing point≥0℃

5. Sulfur content (mass fraction): 0.02%

6. Cetane number of carbon residue in tailings after steam distillation: ≤0.3%

7. Sulfuric acid ash (mass fraction): ≤0.020%

8. Water content (mass fraction): ≤0.05%

9. Impurities (sands, iron, heavy metals): none

10. Copper corrosion resistant grade(50℃, 3h): ≤1

11. Cetane number: ≥49

12. Oxygen stability index (110℃)≥6.0 hour

13. Acid value/(mGkoH/g): ≤0.80

14. Free glycerol contents (mass fraction)≤0.020%

15. Total glycerol content (mass fraction) ≤0.240%

| NO. | Model | Footprint (floor area taken) | Note |

| 1 | 80m2 | Our engineers will help you choose the right size as per customers' factory. | |

| 2 | 120m2 | ||

| 3 | 150m2 | ||

| 4 | 200m2 | ||

| 5 | 300m2 |

| NO. | Model | No. of Workers |

| 1 | 3 | |

| 2 | 5 | |

| 3 | 6-7 | |

| 4 | 10 | |

| 5 | 15 |

Catalyst formula

As mentioned above, catalysts are needed in biodiesel production. One thing that Yilong can help is provide the right catalyst formula, based on which customers can buy catalyst ingredients in their local markets. These catalysts will make processing time shorter and oil quality better.

Warranty

We warranty the complete biodiesel processing system for 2 years. Maintenance service is available throughout the lifecycle. Made of grade 316L stainless steel, Yilong biodiesel equipment is built to last for years to come. If any problem occurs on our equipment (excluding wearing parts) within the warranty period, we'll send engineers to your site for repair once we confirm that that problem is not caused by operator fault.

Why chose Yilong?

Yilong is an expert on biodiesel equipment. Over the years of development, there have been remarkable advances in many aspects of biodiesel processing technology. Huge cost savings, for one thing, is among various reasons why customers opt for Yilong biodiesel processor.

1. Because most waste oils and fats contain heavy fatty acids, our biodiesel equipment uses both liquid and gaseous methanol to catalyze the process for faster reaction. Inside the processor, methanol temperature is strictly controlled to ensure the process consumes minimum electricity thereby saving production costs.

2. The biodiesel equipment comes with a glycerol recycling device. Crude glycerol can be sold on the market, which brings financial benefits and helps reduce waste.

3. After glycerol is removed from the system, methyl esters inside the unit will undergo further treatments to improve yield and quality. This step is not commonly found in any other biodiesel processors.

4. We are among the pioneers in Chinese biodiesel processing technology. We have what it takes to build your industrial biodiesel processing system from the ground up. Call us to get your turnkey project started today.