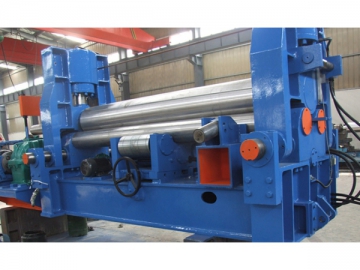

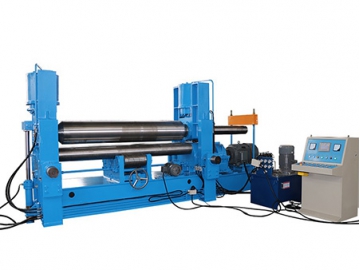

Plate Bending Machine, 3 Roll (Universal Type)

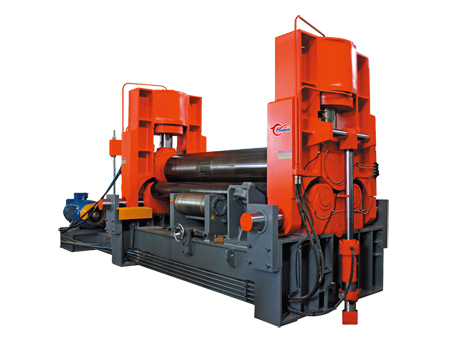

The W11S series universal type 3 roll plate bending machine is a new type hydraulic plate roll developed in recent years. It is mainly composed of top roll, lower rolls, horizontal moving device, guide rolls, main drive system, unloading device , balancing device, left and right frames and machine base. The universal rolling machine can complete one-pass feeding, pre-bending and rolling, ensuring high precision and efficiency.

Features

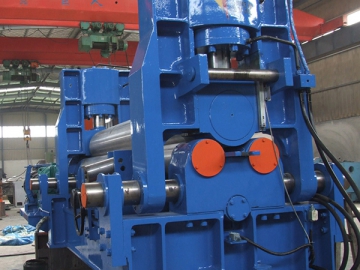

1. This series plate bending machine is designed with a drum-shaped top roll and two small diameter lower rolls. The lower rolls are supported by height adjustable guide rolls to attain high rolling precision.

2. The top roll is capable of moving vertically and horizontally. Plate pre-bending is realized by moving the top roll and enabling it to form an asymmetric geometry with the lower rolls which are driven by motor and reducer.

3. The industrial plate working machinery employs a mobile PLC control panel to control the whole electrical system.

4. Hydraulic components of the plate bending machine are all from Taiwan NORTHMAN, which enable the hydraulic system run stably, flexibly and has no oil leakage.

5. Hydraulic unloading system delivers high reliability in unloading of completely bent cylinder.

6. The standard height of lower rolls is invariable, thus ensuring convenience for feeding and operating. Longitudinal alignment device is equipped for precise plate feeding.

Applicable Industries

The universal type 3 roll plate bending machine are widely used for forming cylindrical, conical, arc, oval, U and other shape components in various industries such as tank truck, chimney, chemical, hydro power, thermal power, shipbuilding, aviation, pressure vessel, pipe, tunnel, bridge, metal structure, machine manufacturing, etc.

Juli's Service Assurance

1. Professional after-sales team, on-site installation and commissioning, free operator training;

2. One-year warranty, free maintenance during warranty period, abundant inventory of quick wear parts

| Model | Max. rolling thickness (mm) | Max. rolling width (mm) | Pre-rolling thickness (mm) | Top roll diameter (mm) | Main motor power ( kw ) |

12× 2000 | 12 | 2000 | 10 | 250 | 5.5 |

| 16 | 2000 | 12 | 255 | 7.5 | |

| 16 | 2500 | 12 | 300 | 11 | |

| 18 | 3000 | 14 | 350 | 11 | |

| 20 | 3000 | 16 | 375 | 15 | |

| 25 | 2500 | 20 | 380 | 15 | |

| 30 | 2500 | 25 | 410 | 22 | |

| 30 | 3000 | 25 | 450 | 30 | |

| 32 | 3000 | 28 | 480 | 30 | |

| 35 | 2500 | 30 | 460 | 30 | |

| 35 | 3000 | 30 | 510 | 37 | |

| 40 | 2500 | 35 | 500 | 37 | |

| 40 | 3000 | 35 | 540 | 45 | |

| 40 | 4000 | 32 | 610 | 45 | |

| 45 | 3000 | 40 | 590 | 45 | |

| 45 | 4000 | 40 | 660 | 45 | |

| 50 | 4000 | 45 | 700 | 55 | |

| 55 | 3000 | 45 | 620 | 55 | |

| 55 | 4000 | 50 | 750 | 55 | |

| 60 | 3000 | 50 | 650 | 55 | |

| 60 | 4000 | 55 | 780 | 75 | |

| 65 | 4000 | 60 | 810 | 75 | |

| 70 | 3000 | 60 | 710 | 75 | |

| 70 | 4000 | 65 | 820 | 75 | |

| 75 | 3000 | 65 | 740 | 75 | |

| 80 | 3000 | 70 | 760 | 75 | |

| 80 | 4000 | 75 | 860 | 90 | |

| 90 | 3000 | 80 | 790 | 90 | |

| 100 | 3000 | 80 | 820 | 90 |

Due to continuous product improvement, actual data might vary slightly. If that happens, please follow the technical parameters of mutual agreement. Juli reserves the right to revise design, construction and specifications without prior notice.

Related Names

Oil Tank Body Making Machine