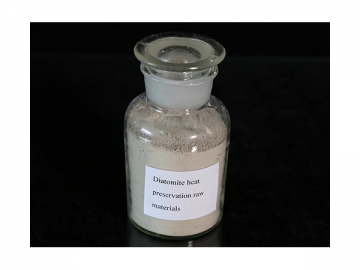

Diatomite Thermal Insulating Material

At Xinhui, as a specialist diatomite manufacturer, we can produce annually 25,000 tons light diatomite and clay heat insulating materials, including 15,000 tons approved products in various specifications and models, 8000 tons slurry materials, coating materials and castables, as wells as 2000 tons other heat insulation fillers. Our products are exceptionally excellent energy saving and thermal insulation materials for such thermal equipment as smelting furnaces, electrolytic bathes, high temperature kilns, etc.

Not only are these refractory materials well sold in domestic market, but they are also a hot sale in various overseas countries including Morocco, Japan, India, Russia, France and more. Our diatomite heat insulating materials include heat insulating bricks, refractory castables, non-calcined diatomaceous earth, calcined diatomaceous earth and diatomaceous earth granules.

To better match the thermal equipment that requires high strength, refractory and thermal insulation materials, Xinghui managed to develop and manufacture A1, A2, B1, B2 and other types of diatomite heat insulating bricks to Japanese standards. Through authentication, the physical and chemical indexes of these refractory bricks completely comply with the JIS R2611-1976 standards.

The refractory castables made from diatomite can work as the heat insulation layer of thermal equipment or as the furnace lining that will not be impacted, not be impregnated by molten metals and directly touch flames. They are known for their perfect heat preservation and insulation functions.

Non-calcined diatomaceous earth, also referred to as natural diatomaceous earth, can be used in conjunction with diatomite heat insulating bricks to build high temperature resistant calcining furnaces. Not only is it used as the base material of heat insulating materials and refractory materials, but it is also used as the fillers between insulating layers.

Apart from non-calcined diatomaceous earth, Xinghui also offers calcined DE. Through high temperature calcination, the calcined diatomaceous earth features obviously improved heat resistance as compared with the natural one. It can be used in a temperature range of 1000~1200℃. As the base material of other heat insulation materials and refractories, it is also used for filling the heat insulting layers and making building mortars.

Diatomaceous earth granules work as the base material of refractory castables and as the material of furnace foundation. According to materials, the thermal insulation materials can be divided into diatomaceous and clayey types. According to granularity, they can be classified into coarse granules, 50-20mm granules and fine granules (<5mm). As needed, diatomite powder is also available.