Mixing Equipment

1. During operation, because the mixing drum has multi-directional actions of motion, it speeds up the fluid and diffused effects of the raw material.

The multi-directional motion mixer avoids segregation and accumulation of materials caused by centrifugal effects.

The two-dimensional motion mixer is widely used in pharmaceutical, chemical, food, dye and pesticide industries. It is especially suitable for mixing large volume solid materials. The mixing barrel swings while it rotates in order to ensure the complete mixing of materials. The mixing machine features high volume mixing capacity as well as convenient discharging.

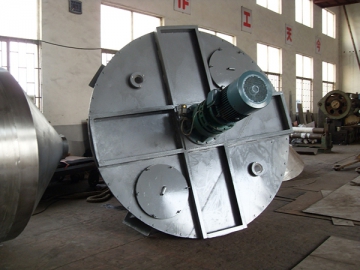

The structure of this mixing machine is specially designed to maximize efficiency. The stainless steel inner wall of the mixing barrel is constructed to effectively mix and discharge the working materials.

The SZH series double cone mixer is a high quality mixing device that helps uniformly combine powder and grain state materials for pharmaceutical, chemical, food and building material applications.

1. The mixing machine uses a vacuum conveyor to feed the powder into the double cone container.

2. As the mixing container rotates continuously, the materials move in an unpredictable pattern for complete uniform mixing.

The rotation of the mixer is carried out by a set of motor and cycloidal needle wheel reducers. The dual screws help stir the material asymmetrically which leads to a more uniform mixing effect. This is particularly desirable for raw materials with a higher difference in their specific gravity and ratio of formulation.

This machine is composed of container, screw stirring paddles and transitional parts; the screw paddle are generally made into 1 layer or 3layers, the outer screw converge is the material to the centre from two sides, and the inner layer of screw conveys the material to the two sides from the centre, so as to from convection mixing, the cubage can be made into rotundity, so the jacket can be played in reaction and drying.

1. The model CH mass mixer is designed to mix powder or damp material in a uniform and efficient process.

2. The mixing chamber of the mixing machine can be effectively sealed to prevent any material leakage.