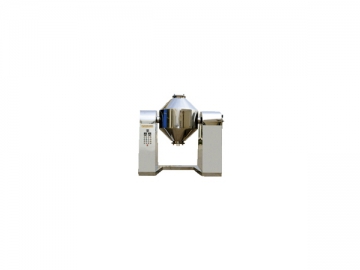

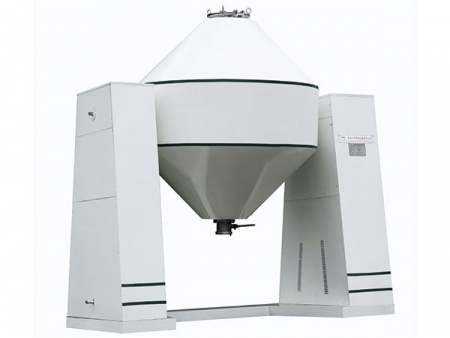

Double Cone Rotary Vacuum Dryer

Features

1. The double cone rotary vacuum dryer can perform mixing and drying functions simultaneously. It also features an optional solvent recovery unit.

2. Advanced design with a simple mixing/drying chamber that is easy to clean.

3.The walls of the inner chamber are designed to steadily rotate and prevent any accumulation of raw materials. This leads to a high coefficient of thermal transmission and results in a quick drying time.

4. This vacuum dryer is an extremely energy efficient drying source and can be used for large quantities of raw materials.

5. Widely used for drying applications for the pharmaceutical, chemical, food and dye industries. Meets GMP requirements.

6. Since the container runs continuously, the heating surface is uniform and will not result in uneven heating which can lead to material burning.

7. No pollution output due to the indirect heating source.

8. Thermal efficiency is two times higher than normal drying ovens.

Principle of Work

The SZG model double cone rotating vacuum dryer features two conical tanks that rotate as they dry and mix raw materials. The heating/mixing chamber is kept in a vacuum state during operation for maximum drying effectiveness. Vaporized moisture from the materials is pumped out through the vacuum exhaust system. Because of the dynamic nature of the drying tanks, the machine is perfect for efficient and uniform drying applications.

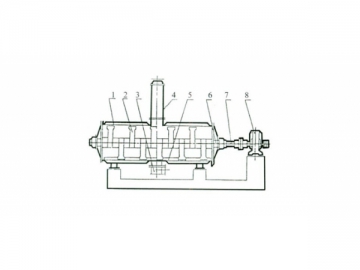

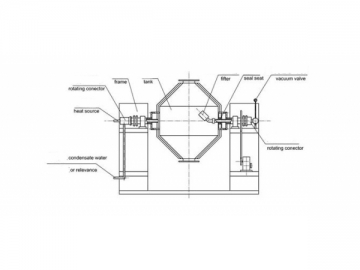

Sketch of Structure

Application

This drying equipment is mainly used for drying the following materials for medicine, chemical and food applications.

1. Thermally sensitive matter.

2. Matter that is easily oxidized.

3. Crystalized matter.

4. Volatile materials.

5. Materials that require moisture collection.

6. Irritating and poisonous materials.

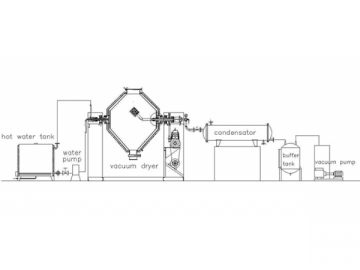

Flow Chart for Solvent Recover System

Technical parameters

Model Selection| Model | SZG100 |

| Volume (litre) | 100L |

| Charging volume (L) | 50 |

| Loading weight(kg) | 40 |

| Heating area(m2) | 1.16 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 0.75 |

| Rotating height | 1750 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 650 |

| Model | SZG350 |

| Volume (litre) | 350L |

| Charging volume (L) | 175 |

| Loading weight(kg) | 120 |

| Heating area(m2) | 1.5 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 1.1 |

| Rotating height | 2100 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 900 |

| Model | SZG500 |

| Volume (litre) | 500L |

| Charging volume (L) | 250 |

| Loading weight(kg) | 200 |

| Heating area(m2) | 2 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 1.5 |

| Rotating height | 2250 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 1200 |

| Model | SZG-7500 |

| Volume (litre) | 750 |

| Charging volume (L) | 375 |

| Loading weight(kg) | 300 |

| Heating area(m2) | 2.63 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 2.2 |

| Rotating height | 2490 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 1450 |

| Model | SZG1000 |

| Volume (litre) | 1000L |

| Charging volume (L) | 500 |

| Loading weight(kg) | 400 |

| Heating area(m2) | 3.5 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 3 |

| Rotating height | 2800 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 1970 |

| Model | SZG1500 |

| Volume (litre) | 1500L |

| Charging volume (L) | 750 |

| Loading weight(kg) | 600 |

| Heating area(m2) | 4.61 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 4 |

| Rotating height | 2940 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 2280 |

| Model | SZG2000 |

| Volume (litre) | 2000L |

| Charging volume (L) | 1000 |

| Loading weight(kg) | 800 |

| Heating area(m2) | 5.58 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 5.5 |

| Rotating height | 2990 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 2500 |

| Model | SZG3500 |

| Volume (litre) | 3500 |

| Charging volume (L) | 1750 |

| Loading weight(kg) | 1000 |

| Heating area(m2) | 7.5 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 7.5 |

| Rotating height | 3490 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 2700 |

| Model | SZG5000 |

| Volume (litre) | 5000 |

| Charging volume (L) | 2500 |

| Loading weight(kg) | 1800 |

| Heating area(m2) | 13.8 |

| Rotating speed(rpm) | 3~13 |

| Motor power | 15 |

| Rotating height | 4200 |

| Desigh pressure insider the tank: ---0.1~0.15Mpa | |

| Desigh pressure inside the jacket: ≤0.3Mpr | |

| Total weight (Kg) | 2900 |

Note:

1. The above-mentioned parameters are calculated based on material density 0.6g./cm3.

2. For raw materials, if its volume has a significant change before and after drying, then its filling coefficient may be increased or decreased suitably.

3. Adjustable motor speed 0~6rpm according to user's requirement.

The following aspects should be taken into consideration when ordering.

1. if certificate for pressure vessel is a requirement, please indicate that in the order.

2. if glass lining for interior surface is a requirement, please let us know.

3. If your materials are explosive, or flammable, the calculation should be made according to trial results. If material has larger specific weight, it should be noted upon placing the order。

Instructions to ordering

1. Three heat source options steam, hot water, heat conduction oil.

2. When ordering, please indicate the operation temperature of the dryer in order to choose or provide the suitable heat source for you.

3. When drying viscous raw material, our factory will design a special stirring device in the chamber.

4. The auxiliary parts of the vacuum drying system can be supplied and installed by our factory. Please indicate when ordering.

5. If you have any special requirements, our factory can also design, manufacture and install as requested.