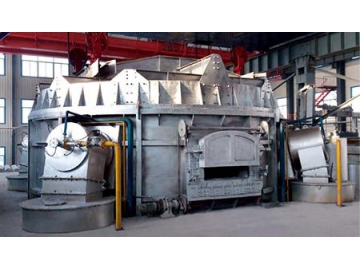

Melting Furnace, Stationary Type

Generally, aluminum manufacturers and aluminum cast project contractors have strict requirements for capacity, finished product quality and project delivery cycle when choosing a casting machine. Liancheng's stationary type melting furnace can perfectly meet their needs. The aluminum melting furnace can use heavy oil, diesel, natural gas and LPG as its fuel, and it has realized 3t~35t production capacity. It comes in arch roof, flat roof and full-mold casting constructions. Different construction has direct influence on the capacity and cost of the melting furnace.

Introduction

1. Stationary melting furnace is constructed from steel shell, refractory bricks and castables. The maximum furnace temperature is up to 1000℃. Therefore, it is ideal for melting aluminum ingots, or aluminum and copper scraps.

2. Equipped with a regenerative burning system, it can save 20% fuels, thus reducing cost while improving efficiency.

3. Thanks to a tilting furnace door design, the foundry machinery is more suitable for material feeding by forklifts. This can improve production efficiency.

Our stationary type melting furnace comes with two kinds of burning system, i.e. high speed burner-type burning system and regenerative burning system

The burning system of this aluminum melting furnace employs automatic ignition and flame detection control method, providing gas pressure protection and flame out protection. It comes with two burners in the furnace. Their maximum load is up to 160×104kcal/h. This aluminum melting system can offer 3t/hr~4t/hr melting efficiency.

Technical Parameters

Natural gas pressure: 10~15Kpa

Wind pressure: ≥450mmH2O

Natural gas calorific value: 8400kcal/Nm3

Burner load: 160×104kcal/h

Main Configuration Parameters

Natural gas flow: 200Nm3/h per furnace

Natural gas branched pipeline: DN50

Natural gas main pipeline: ≥DN80

Manual air valve: DN150

Air blower: 7.5kw

Burner Configurations

Burning system

Control system

Pipe system

The melting furnace is mainly used in the aluminum profiles and aluminum sheets foundry workshops for remelting aluminum ingots, melting deformed aluminum alloy, heating up molten aluminum, refining and drossing, etc.

Principle

Special material feeding devices such as forklifts are used to feed solid materials like aluminum ingots, scraps, etc. After feeding, regenerative burner can rapidly melt the materials. Then it can effectively and sufficiently mix the molten aluminum so as to make its temperature and composition more uniform.

Features

1) Designed with a large rectangular door, the melting furnace is especially convenient to remelt waste aluminum profiles, realizing quick charging effect, and thus achieving extremely high production efficiency.

2) Regenerative burner is used to recycle waste heat from exhaust gas. So, flame temperature in the furnace can be increased, and heat efficiency of the melting furnace is considerably improved.

3. The regenerative burner can be installed at bottom or top of the casting equipment, delivering high flexibility.

4. The furnace applies state-of-the-art burning control system that complies with the standard of EN746-2, and PLC with user-friendly interface. They provide high convenience for users.

| Capacity | 3t~35t |

| F uel | Heavy oil, diesel, natural gas and liquefied petroleum gas |

| Fuel Consumption (different fuels used for melting aluminum scraps containing over 90% aluminum ingots) | |

| Melting Furnace with High Speed Burner (Melting 1t Aluminum Ingots) | Consume 80kg diesel |

| Consume 85kg heavy oil | |

| Consume 37m3 LPG | |

| Consume 95m3 natural gas | |

| Melting Furnace with Regenerative Burner (Melting 1t Aluminum Ingots) | Consume 65kg diesel |

| Consume 70kg heavy oil | |

| Consume 30m3 LPG | |

| Consume 78m3 natural gas | |

| Melting speed | 3t/hr~43t/hr |

| Type and Advantages | |

| Arch Roof Type | Cheaper; ideal for low capacity melting furnace with vertical door |

| Flat Roof Type | Moderate price; more durable than arch roof type; suitable for melting furnaces of all kinds of capacities |

| Full Casting Type | Expensive; excellent in heat preservation, most robust, long service life |