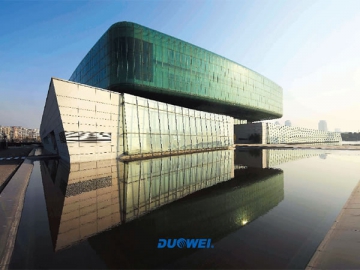

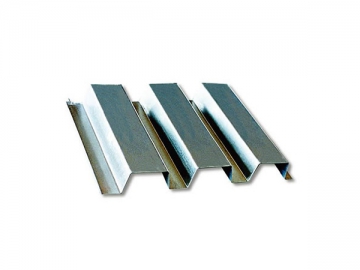

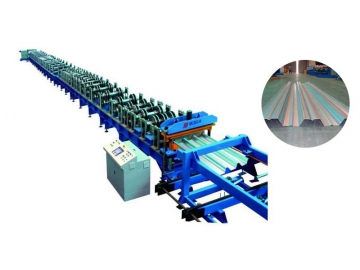

Composite Floor Deck

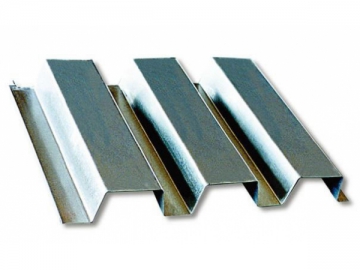

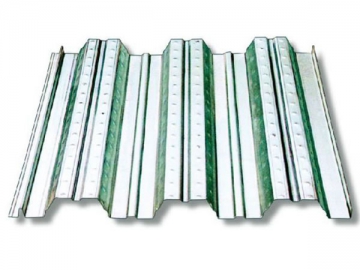

Duowei profiled sheet composite floor decks are used for permanent construction projects to bear construction load and concrete weight. In the use stage, the profiled sheets will be used as the bottom reinforcing bar.

Eight advantages

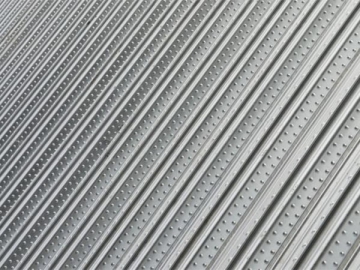

There are pre-processed slots between the corrugations of the profiled steel plates, available for engineering use like electricity and communications.

The dead load of the entire structure is reduced, saving the basic cost of the lower part.

During construction, the profiled steel plate can enhance the lateral stability of the supporting steel beam.

It gives full play to the mechanical properties of two materials - steel and concrete.

It does not require formwork, getting rid of the removal and installation of form works.

The profiled sheet is equal to tensile main rib based on calculation, only moisture reinforcements are needed.

The profiled steel plates provide an even ceiling surface for concrete buildings.

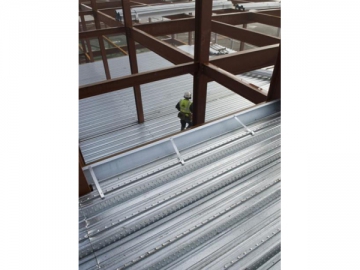

After installation, the composite floor deck can be used as a safety work platform for workers, tools, materials and equipment.

Eight major characteristics

Strong concrete bond shear resistance

With a special closed-rib design, good longitudinal shear-bearing capacity, there will never be slippage between the steel bearing plate and the concrete upon closed built-up slabs within the design load limit.

Excellent fire performance

The ribs of the slab are completely encased in concrete, just like the cast-in reinforcement. Closed built-up slabs can completely replace the positive moment tensile reinforcement in the floor slabs, and an 1.5-hour refractory power can be achieved without need to brush fire-resistant coating

Superior section of built-up slabs

Closed built-up slabs have a higher effective height of the floor slab and a bigger combination stage to provide a more powerful positive moment resistance.

Board (Slab) end slot-type suspension system

For the use of ceilings, ceiling, plumbing installation, etc., no need for drilling or welding; during the building period, it can be moved, removed or reinstalled, according to the need.

Simple, rapid construction

It does not require any plug, with no leakage of mortar, shortening the construction cycle.

Even slab bottom appearance

The slab bottom is even, it is aesthetically appropriate for buildings without planned ceilings.

Effectively reduce the slab height

According to fire regulations and shatterproof requirements, the total thickness of the closed built-up slab is only 110-130 mm, 30-40 mm less than the opening profiled steel plate composite slab, thus getting a reduced self weight.

Low cost

The reinforcements bearing the positive moment of the closed built-up slabs are replaced by the profiled steel plates, without need to brush fire-resistant coating, thus reducing the usage of reinforcements and cutting down the costs.

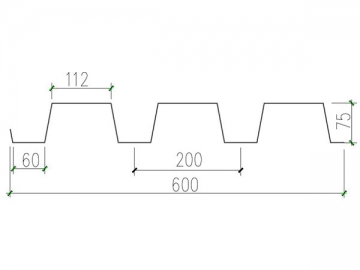

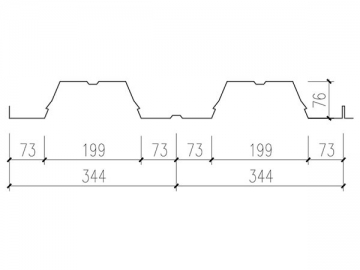

| Board thickness (mm) | Profiled sheet weight ( kg /m2) | Inertia moment I (cm4/m) | Cross sectional moment of inertia W |

| 0.75 | 9.78 | 118.58 | 31.26 |

| 0.90 | 11.77 | 142.29 | 37.51 |

| 1.00 | 13.08 | 158.10 | 41.68 |

| 1.20 | 15.70 | 189.72 | 50.02 |

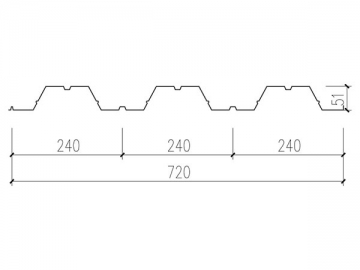

| Board thickness (mm) | Profiled sheet weight ( kg /m2) | Inertia moment I (cm4/m) | Cross sectional moment of inertia W |

| 0.75 | 8.18 | 48.41 | 15.52 |

| 0.90 | 9.81 | 58.10 | 18.62 |

| 1.00 | 10.90 | 64.55 | 20.69 |

| 1.20 | 13.08 | 77.46 | 24.82 |

| Board thickness (mm) | Profiled sheet weight ( kg /m2) | Inertia moment I (cm4/m) | Cross sectional moment of inertia W |

| 0.75 | 8.56 | 112.39 | 26.76 |

| 0.90 | 10.27 | 134.87 | 32.11 |

| 1.00 | 11.41 | 149.85 | 35.68 |

| 1.20 | 13.69 | 179.82 | 42.82 |

| Board thickness (mm) | Profiled sheet weight ( kg /m2) | Inertia moment I (cm4/m) | Cross sectional moment of inertia W |

| 0.75 | 11.54 | 92.44 | 21.01 |

| 0.90 | 12.47 | 99.84 | 22.69 |

| 1.00 | 13.85 | 110.93 | 25.21 |

| 1.20 | 18.47 | 147.90 | 33.61 |

| Board thickness (mm) | Profiled sheet weight ( kg /m2) | Inertia moment I (cm4/m) | Cross sectional moment of inertia W |

| 0.75 | 9.81 | 40.54 | 11.50 |

| 0.90 | 11.77 | 48.65 | 13.9 |

| 1.00 | 13.08 | 54.09 | 15.44 |

| 1.20 | 15.70 | 64.86 | 18.53 |

| Board thickness (mm) | Profiled sheet weight ( kg /m2) | Inertia moment I (cm4/m) | Cross sectional moment of inertia W |

| 0.75 | 10.22 | 80.22 | 16.71 |

| 0.90 | 12.26 | 96.31 | 20.06 |

| 1.00 | 13.63 | 111.13 | 23.62 |

| 1.20 | 16.32 | 132.7 | 28.24 |

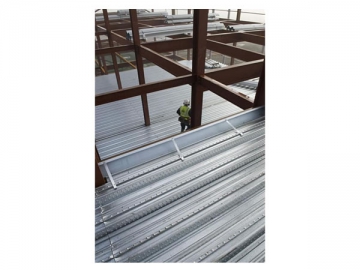

Construction steps

I. Size rechecking and line snapping

1. Size of axis: recheck whether size of axis for steel girder installation meets layout of profiled sheet;

2. Surface treatment of girder: determine ring on the steel girder top surface is removed and smoothed, and rust scale, greasy dirt and sundries on the girder surface are cleaned;

3. Position line: profiled sheet laying starting line and middle control line should be snapped on the girder top surface in accordance with layout of profiled sheet. The laying starting line should indicate laying direction and steel sheet hanging bundle number. The middle control line also can be used as the laying starting line when laying by sections.

II. Hanging and laying

1. DUOWEI profiled sheet should be constructed in accordance with approved laying drawing. Attention should be paid to the design support strength of structural member when bundled profiled sheets are placed on the structure to prevent exceeding their allowable load;

2. When DUOWEI profiled sheets are piled up in bundles, many girders should be crossed, and when they are placed between two girders, attention should be paid to the support width at both ends to avoid falling accident caused by toppling;

3. After DUOWEI profiled sheets are hoisted in place, they should be in position piece by piece from the snapped laying starting line of steel sheet along the laying direction, and plate joint should be properly adjusted after reaching the control line;

4. In case of big wind, construction should be stopped and unpacked profiled sheets should be immediately re-bundled; otherwise, they may be blown up by the wind, thereby causing accident or damaging the profiled sheets.

III. Fixation

1. DUOWEI profiled sheet should be immediately fixed onto the structural member through welding after being fixed;

2. Any laid but unfixed pro