Truss Floor Deck

DUOWEI steel bar truss floor deck is the integrated fabricated formwork for which steel bar is to be processed into steel bar truss and then the steel bar truss is to be welded with galvanized profiled sheet. In the construction stage, the steel bar truss floor deck can bear the construction load; moreover, concrete can be poured after steel bars are directly laid on the beam for simple steel bar works. As form functions can be completely replaced, form erection and removal works can be reduced, so floor slab construction efficiency can be greatly improved.

DUOWEI steel bar truss floor deck has features such as economy, convenience, safety and reliability, etc and it has been widely used by structure and building fields such as multilayer workshops, multilayer, high-rise and ultra-high steel structure buildings and various irregular floors, concrete structures and high speed railway, etc.

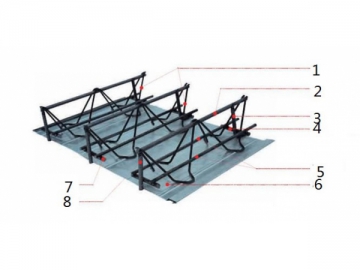

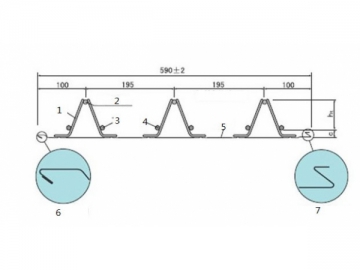

1. Web rebar

2. Upper rebar

3. Vertical support rebar

4. Horizontal support rebar

5. Lower rebar

6. Deck

7. Horizontal support rebar

8. Vertical support rebar

Features

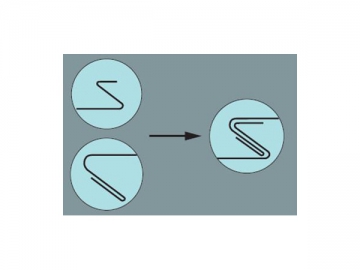

1. Unique double folding design

Effectively increases board edge strength; hard to bend or deform during transportation and construction. Allows for easy fastening at the bottom.

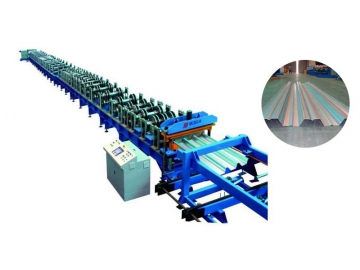

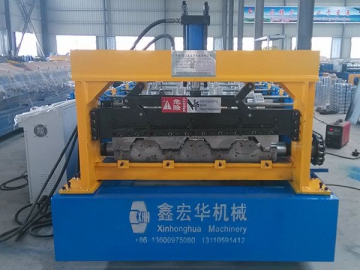

2. Improved form spot welding technology

Original form spot welding equipments are improved to make welding current of many welding heads more balanced and stable, so the floor deck will be free from cold joints or weld penetration phenomenon.

Double folding design

Double folding design Four advantages

1. Economic

The load-bearing of the truss is able to support weight without added structures that could add to the cost of construction.

2. Convenient

Field steel binding is reduced by 60-70% and construction is much quicker.

3. Safe

The mechanical property is basically the same as a traditional floor slab with increased crack resistance. The bottom die is not loaded in the use phase, eliminating fire and corrosion risks.

4. Reliable

The reinforcements are arranged uniformly. The two-way stiffness of the floor slabs are similar which is conducive to seismic stud welding.

1. Web rebar

2. Upper rebar

3. Lower rebar

4. Deck

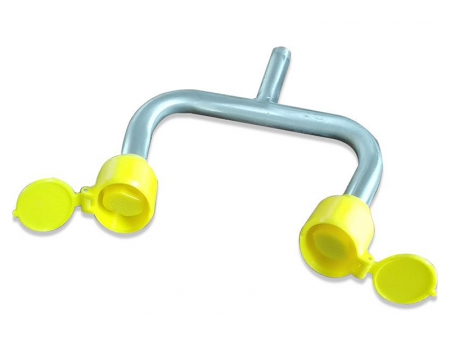

5. Connection clip of deck

6. Connection clip of deck

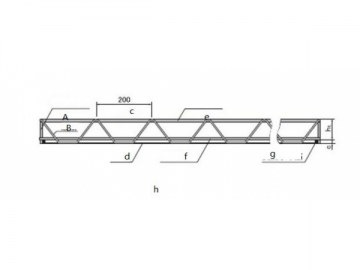

A. Web rebar

B. Upper rebar

C. Vertical support rebar

D. Horizontal support rebar

E. Lower rebar

F. Deck

G. Horizontal support rebar

H. c-thickness of the protective layer of concrete. hc-height steel armor

Material parameters

Upper and lower steel bar: uses grade 3 hot rolled coiled steel bar HRB400 or cold rolled ribbed steel bar CRB550

Web member steel bar: uses cold rolled plain steel bar

Bottom form steel sheet: can use galvanized steel sheet or cold rolled steel sheet according to different applications, normal thickness is 0.4~0.5mm, double size galvanization 120g/m2

| Name | Specification | |

| Upper chord steel bar diameter | 6-12mm | |

| Lower chord steel bar diameter | 6-12mm | |

| Web member steel bar diameter | 4-7mm | |

| Steel bar truss height | 70-270mm | |

| Support horizontal steel bar diameter | 8 、 10mm | |

| Support vertical steel bar diameter | HPB235 | 12 (for h≤150), 14 (for h > 150) |

| HRB335HRB400 | 10 (for h≤150), 12 (for h > 150) | |

| Bottom form steel sheet thickness | 0.4-0.8mm | |

| Bottom form steel sheet width | 590mm | |

| Concrete protective layer thickness | 15-30mm | |

| Steel bar truss floor deck length | 1.0-12.0m | |

Product system

We cut out the factors which could lead to an increase in the cost of materials.

The purpose of profild sheet is changed, and it is just used as the template in construction stage of floor plate, reducing the used amound of profiled sheet and lowering requirements on anti-corrosion coating of profild sheet.

We change the stress mode of floor plate during construction stage

In construction stage, stiffness is provided by steel bar truss instead of by profild sheet.thus, greater stiffness of floor plate can be provided, applicable to larger floor plate span without support.

All of these measures reduces future maintenance costs.