Auto Parts

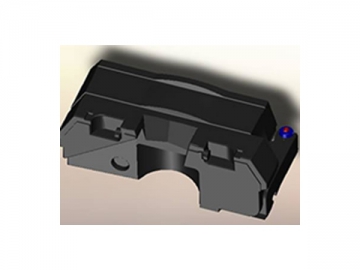

Originally, the roofs of forklift truck and bulldozer are made from iron plates. They have to be maintained frequently in that the iron plate is easy to rust away. In addition, iron plate leads to unbearably hot cab at high temperature whereas freezing cold cab in winter. Therefore, more and more automobile manufacturers start making one-step molded roofs using rotational molding process. Such Rotational Moulding for Auto Parts are not only heat insulating, but also maintenance free. They come with elegant appearance while providing gorgeous color.

Custom Range:

Chunyang can make rotomolded automobile parts to customers’ needs including car roof, water tank, fender, car bumper, ATV trunk box, etc.

Raw Materials:

The rotomolded parts are made from SCG, Exxon Mobil or other brands LLDPE materials. Other materials are also optional if required.

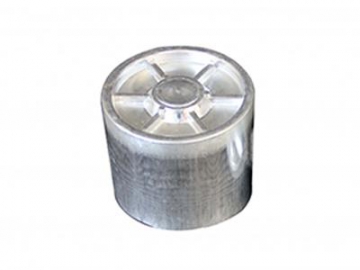

Molds:

Molds used for making the Rotational Moulding for Auto Parts are cast from top quality aluminum material using special processes. They are free from sand holes and bubbles, and allow for excellent roto molded products with uniform wall thickness and air tightness.

Delivery Cycle:

Based on customers’ order, the delivery cycle of the automobile components is within 20 days.

Finished Products Show:

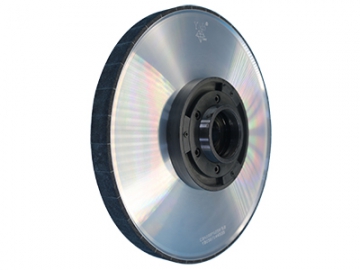

See part of typical examples of our Rotational Moulding for Auto Parts below.

-

ATV seat -

ATV trunk box -

Auto water tank -

Car bumper -

Fender -

Roof of truck

For more information about Chunyang’s rotomolded products and rotational molding process, please click the links: ,