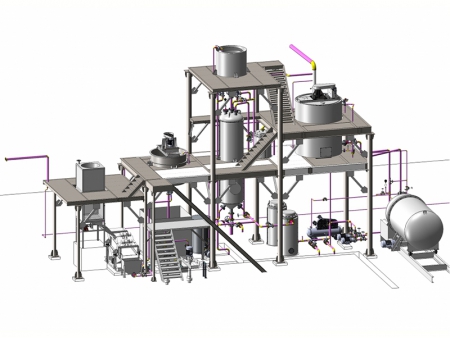

Engineering Machinery

Fuel tanks and water tanks of construction vehicle and special purpose vehicle are mostly made from LLDPE using rotational molding process. For the products with special and complex shapes, especially, this process is a perfect choice. It enables one-step molding, making sure that the engineering machinery parts boast excellent resistance to impact and corrosion, high safety, and other remarkable advantages.

Custom Range:

Rotomolded fuel tanks, water tanks, bumpers, interior trim parts, etc. for engineering vehicles.

Raw Material:

LLDPE of well renowned brands such as SCG, ExxonMobil, etc.;

Other materials: optional according to customers’ needs.

Molds:

Chunyang boasts cutting-edge technology in rotational molding tooling development. Fabricated from high quality aluminum in unique process, our molds are free from sand holes and bubbles, and thereby the rotomolded parts for engineering machinery manufactured in them feature uniform wall thickness and high air tightness.

Delivery Cycle:

According to the order quantity of customer, the delivery cycle of our rotomolded engineering machinery parts is within 20 days.

Finished Products Show:

Typical examples include but not limited to:

-

Automotive fuel tank -

Automotive fuel tank -

Machinery oil tank -

Machinery oil tank -

Urea tank -

Water tank

For more information about Chunyang’s rotomolded products and rotational molding process, please click the links: ,