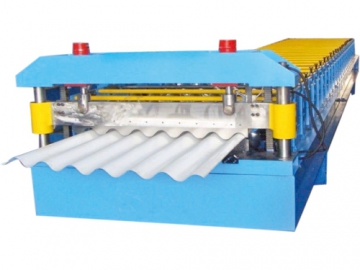

Roll Forming Machine (for Corrugated Sheet)

Request a Quote

| Item | Roofing Corrugated Sheet Roll Forming Machine | |

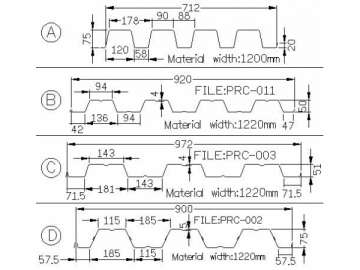

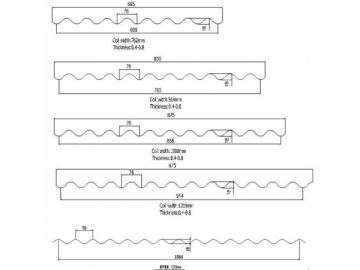

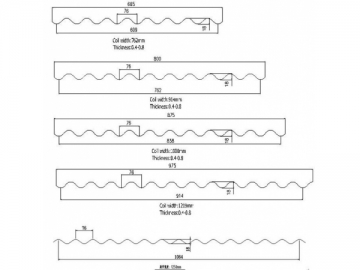

| Coil Material | Thickness | 0.3-0.8mm |

| Coil width | Custom-made, 1000mm or 1200mm or 1250mm | |

| Yield Strength | 250-350 Mpa | |

| Material | PPGI, Color Steel, GI. | |

| Decoiler / Uncoiler | Decoiler Type | Manual or Hydraulic or Auto Type |

| Coil Width | Max. 1250mm | |

| I.D | 508-610mm | |

| O.D | Max. 1500mm | |

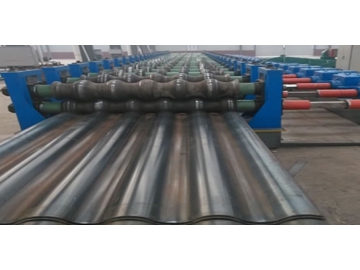

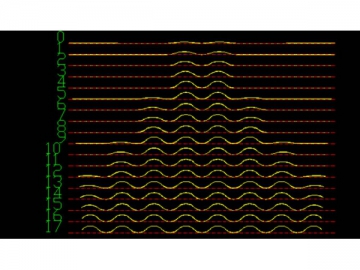

| Corrugated Sheet Roll Forming Machine | Forming Stations | 16 Stations ( Depend on Profiles ) |

| Roller material | 45# steel, surface coated with 0.05mm hard chrome | |

| Diameter of shaft | 76mm | |

| Shaft material | High grade 45# steel | |

| Drive type | Chain transmission | |

| Forming speed | 0-15m/min | |

| Main power | 5.5KW | |

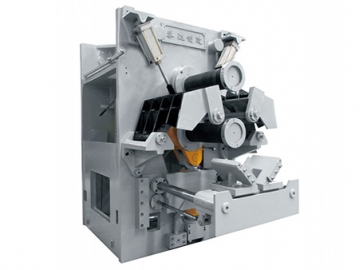

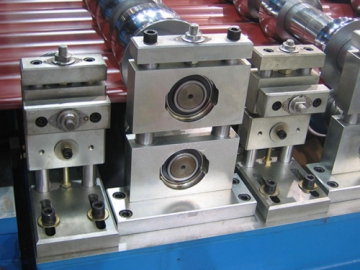

| Cutting | Cutting type | Hydraulic cutting |

| Cutting Die Material | Cr12Mov steel, HRC58-62 | |

| Cutting power | 3KW | |

| CuttingTolerance | 10m /-1.5mm | |

| Encoder | OMRON Brand | |

| Electrical control | PLC | PANASONIC Brand |

| Inverter | PANASONIC Brand | |

| Touch screen | PANASONIC | |

| Operation type | Touch screen & Button | |

| Hydraulic Station | Hydraulic station | Famous Chinese brand |

| Runout Table | Table type | Simple nonpower type |

| Function | To support the finished panels | |

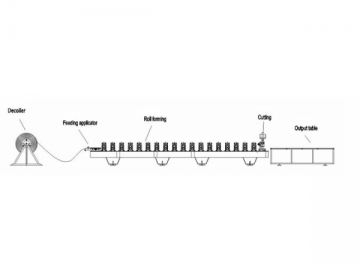

| Decoiler / Uncoiler | 1 Unit |

| Feeding Guide | 1 Unit |

| Main Corrugated Sheet Roll Forming Machine | 1 Unit |

| Hydraulic Cutting Device | 1 Unit |

| Hydraulic Station | 1 Unit |

| PLC Computer Control Board | 1 Unit |

| Runout Table | 2 Units |

Our Advantage

1.High Quality

2.Reasonable Price

3.Good after Service

4.1 Year Warranty

5.More than 16 years of experience

6.CE certification

7.ISO9001

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos