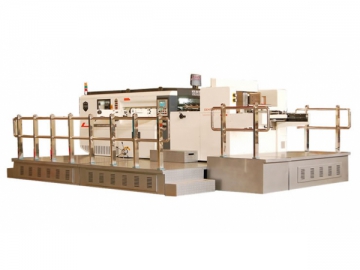

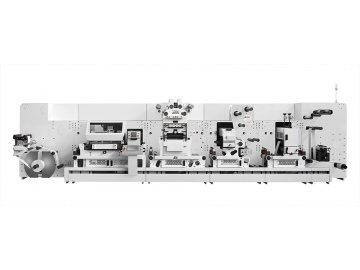

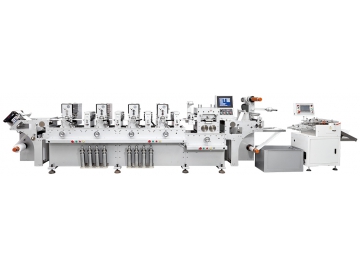

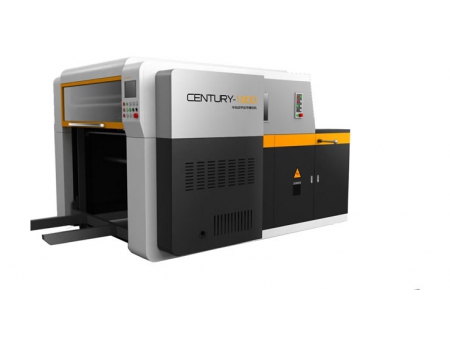

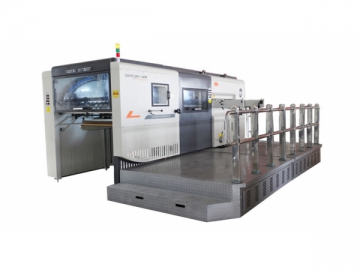

MWB-Q Series Semi-Automatic Flatbed Die Cutting Machine

When customers come to Century, one of the most popular semi-automatic die cutting machines they request from us is in the MWB-Q series. These flatbed die cutters are equipped with a stripping section, For they are equipped with stripping section, which means less stripping work and shorter delivery for packages users.

The stripping unit uses a centerline system and a pneumatic lock-up system for a fast and safe stripping die set up and job change. Processed board's three sides and middle part can be cleaned by double stripping function

Features of the MWBQ series semi-automatic flatbed die cutting machine include:

CE certified

Stripping system

Siemens latest PLC technology

European, Taiwanese and Japanese standard spare parts

ISO9001:2008 approved manufacturing process.

1.Feeding Section

Effective manual feeding system.

Automatic sheet pile lifting system.

Side guide to position paper pile center.

Applicable to E, B, C, A flute and double wall.

2.Die Cutting Section

The centerline system is used for a quick cutting die set up and job changeover.

A pneumatic lock up system ensures safe and operator friendly changeover of the die cutting plate.

3. Stripping Section

Three sides and the middle of the board can be stripped.

An electrically controlled auto-lifter controls the upper stripping tool when stripping is not needed.

The centerline system is used for a quick stripping die set up and job changeover.

4.Delivery Section

Optional function: tape inserter .

Side and front joggers to ensure neat stacking.

Two delivery options available: pallet or trailer.

Photoelectric detective device for safety entrance and operation.

5.Electrical Control Section

The electrical control system uses the latest Siemens PLC technology for a trouble free machine operation.

We also use electric components from internationally known brands for local and quick service and maintenance.

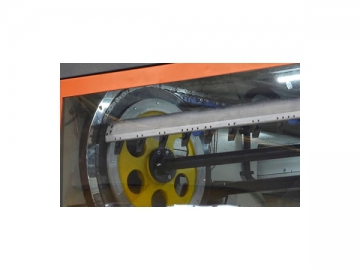

6. Main Drive Chain

A heavy load and highly precise chain achieve a high tensile strength and wear resistance.

7. Main Driving System

A mono-block casting chassis reduces vibration and achieves a more stable performance, as well as a longer lifespan.

A deepened oil tank allows part of the worm wheel to work under lubrication oil for a better all-around lubrication.

| Model | |

| Maximum paper size | 1180*900mm |

| Minimum paper size | 450*400mm |

| Maximum cutting size | 1160*880mm |

| Maximum cutting pressure | 200 T |

| Stock range | Corrugated board up to7mm |

| Cutting precision | ±0.5mm |

| Maximum speed | 4,200 s/h |

| Pressure adjusting range | ±1mm |

| Minimum front waste | 8mm |

| Inner chase size | 1190*910mm |

| Machine dimension (L*W*H) | 6825*4275*2400mm |

| Total power | 13.3 kw |

| Machine's weight | 14 T |

| Model | |

| Maximum paper size | 1330*980mm |

| Minimum paper size | 550*480mm |

| Maximum cutting size | 1300*960mm |

| Maximum cutting pressure | 250 T |

| Stock range | B, C, A flute and double wall |

| Cutting precision | ±0.5mm |

| Maximum speed | 4,200 s/h |

| Pressure adjusting range | ±1mm |

| Minimum front waste | 8mm |

| Inner chase size | 1330*990mm |

| Machine dimension (L*W*H) | 7440*4640*2425mm |

| Total power | 17 kw |

| Machine's weight | 17 T |

| Model | |

| Maximum paper size | 1480*1080mm |

| Minimum paper size | 480*550mm |

| Maximum cutting size | 1450*1050mm |

| Maximum cutting pressure | 300 T |

| Stock range | B, C, A flute and double wall |

| Cutting precision | ±0.5mm |

| Maximum speed | 40,00 s/h |

| Pressure adjusting range | ±1mm |

| Minimum front waste | 8mm |

| Inner chase size | 1480*1080mm |

| Machine dimension (L*W*H) | 7750*4860*2440mm |

| Total power | 21 kw |

| Machine's weight | 19 T |

| Model | |

| Maximum paper size | 1650*1210mm |

| Minimum paper size | 550*650mm |

| Maximum cutting size | 1620*1190mm |

| Maximum cutting pressure | 300 T |

| Stock range | B, C, A flute and double wall |

| Cutting precision | ±0.5mm |

| Maximum speed | 36,00 s/h |

| Pressure adjusting range | ±1mm |

| Minimum front waste | 10mm |

| Inner chase size | 1646*1220mm |

| Machine dimension (L*W*H) | 8150*5155*2500mm |

| Total power | 21 kw |

| Machine's weight | 24 T |