Metal Stamping

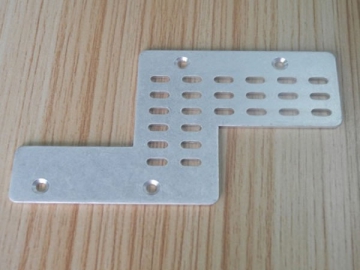

In case you didn't know, metal stamping is a process that involves little or no cutting operation. During a typical run, the stamping press uses its die set to exert sufficient pressure on the materials it works on, causing it to deform or break apart so the desired shape or size is obtained.

For over a decade, YunPeng has been dedicated to providing the best metal stamping service available on the market, and we continue to do so by investing heavily in advanced metal stamping equipment and an engaged team of tooling design experts and metal fabrication professionals.

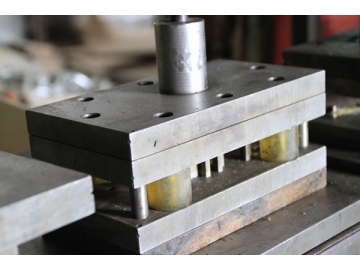

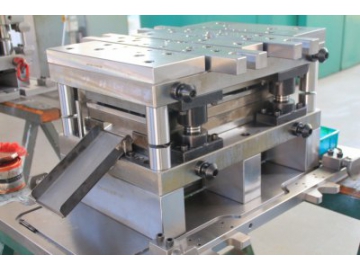

The die set we use in metal stamping is something we take seriously. Its size and shape determines the dimensional and geometrical accuracy of the resultant stamped components. The die set is required not to damage the surface of parts being stamped, and it is often rated for longevity. This is to make sure our metal stamping process can produce consistent results (a.k.a., repeatability), yielding parts that not only look identical but also can be used interchangeably.

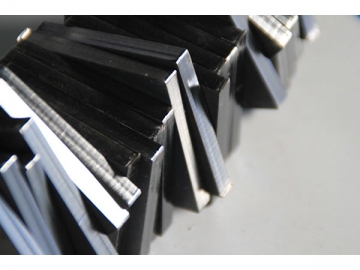

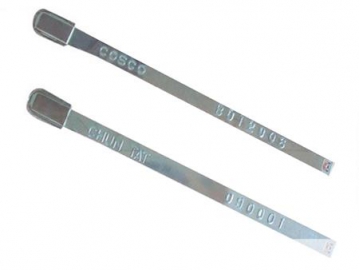

YunPeng does not shy away from complex, hard-to-stamp parts. In fact, we excel at some of the most complicated metal stamping jobs that our competitors can't possibly do. The size of materials we can work on covers a wide range as well. They can be as small as the second hand of a clock, or as large as car panels and cross beams. Better still, metal stamping is a cold working process that tends to strengthen the materials being stamped by plastic deformation, which is why stamped parts can have improved rigidity and strength.

We own and operate a total of 50 stamping presses in load capacities ranging from 16t to 500t. Materials we work on can be up to 16mm thick, all while we can maintain a tight tolerance of ±0.02mm. The minimum thickness we can handle is 0.3mm.

Equipment

Stamping press

Raw Materials, Parts

We specialize in stamping a variety of metal materials, including hot-rolled steel plates, cold-rolled steel plates, bar stocks, stainless steel, aluminum and brass.

We also do all the surface treatment works in-house, including hot-dip galvanizing, nickel plating, chrome plating, oxidation, polishing, and salt spray test.

Customers come to us from various industries. Their products are numerous, including furniture, auto parts, and building materials.